Process chamber and process method

A process chamber and process technology, applied in the field of process chambers, can solve problems such as failure, insufficient electrostatic adsorption, influence on film growth, photolithography, etc., to reduce temperature difference, reduce peeling, improve process stability and The effect of process results

Pending Publication Date: 2022-07-29

BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, since the target atoms will be deposited on the lining, and the stress of the titanium nitride film is relatively large, and the plasma bombarding the target will generate a lot of heat, the lining will have a large temperature difference between the process and the non-process (greater than 50°C), therefore, the titanium nitride film on the lining will be easily peeled off from the lining to form particles, if the particles formed by the peeled titanium nitride film stick to the back of the wafer (wafer The side facing the electrostatic chuck) will cause insufficient electrostatic adsorption of the electrostatic chuck to the wafer during the subsequent process, resulting in wafer offset or even wafer transfer failure resulting in debris. If the particles formed by the peeled titanium nitride film stick to the The front side of the wafer will affect the subsequent film growth, lithography (Litho) and etching (Etch), resulting in poor process stability and poor process results

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] In order for those skilled in the art to better understand the technical solutions of the present invention, the process chamber and the process method provided by the present invention are described in detail below with reference to the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

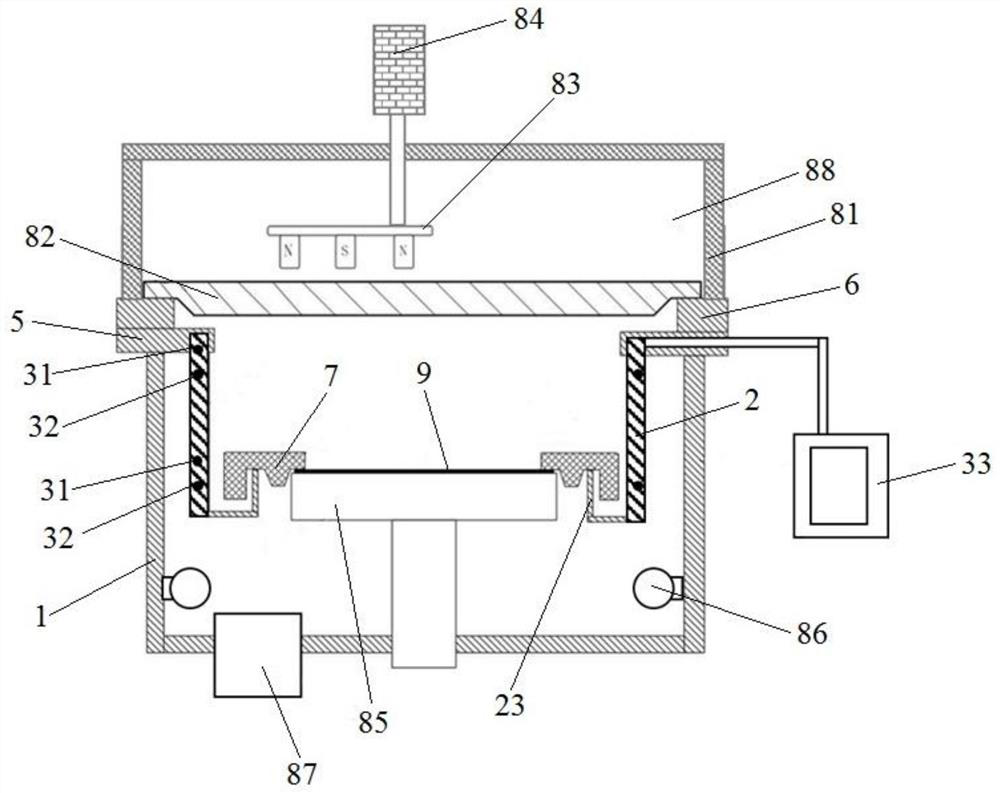

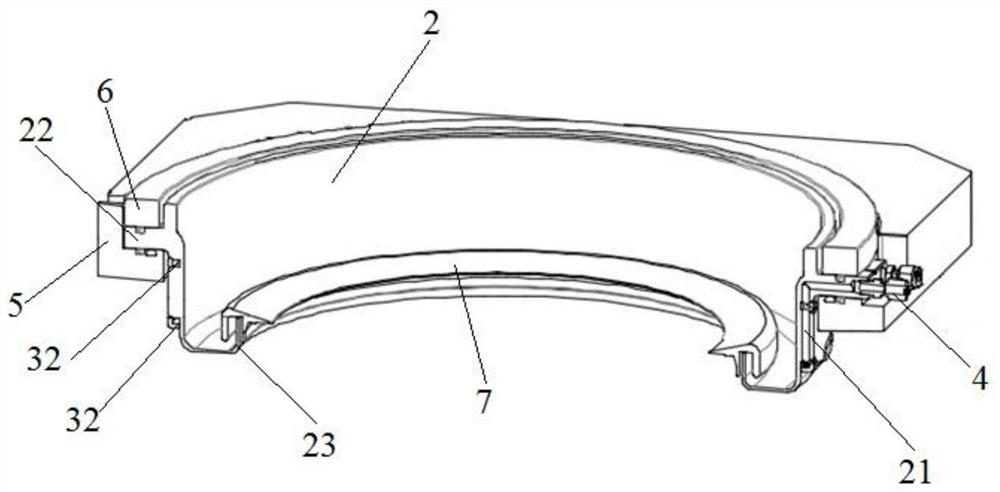

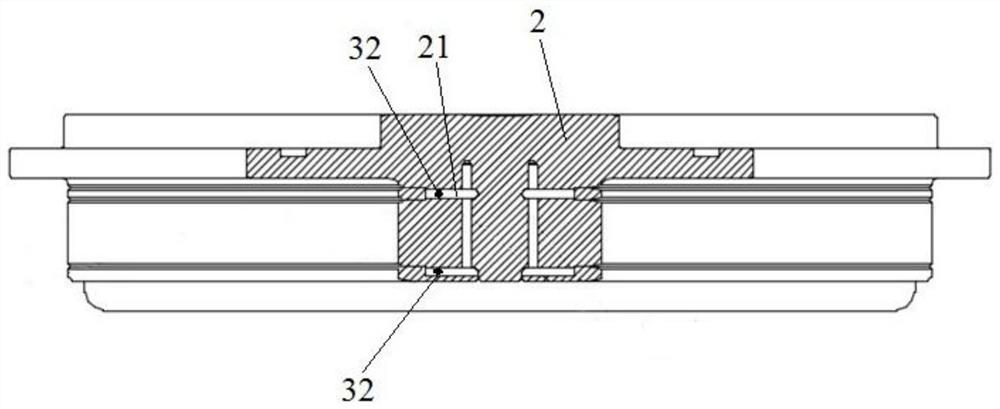

The invention provides a process chamber and a process method.The process chamber comprises a chamber body, a lining, a temperature control part and a control piece, and the lining is annular, is arranged in the circumferential direction of the inner circumferential wall of the chamber body and is used for shielding the inner circumferential wall of the chamber body; the temperature control part is arranged on the lining and is used for detecting the temperature of the lining and heating the lining; the control part is electrically connected with the temperature control part and used for controlling the temperature control part to heat the lining when the real-time temperature of the lining does not reach the stable temperature according to the stable temperature and the real-time temperature, detected by the temperature control part, of the lining in the semiconductor technology so that the temperature of the lining can be controlled. According to the process chamber and the process method provided by the invention, the temperature difference of the lining in the process and when the process is not carried out can be reduced, and the stripping of sediments is reduced, so that the process stability and the process result can be improved.

Description

technical field [0001] The present invention relates to the technical field of semiconductor equipment, and in particular, to a process chamber and a process method. Background technique [0002] In some semiconductor processes, a physical vapor deposition (Physical Vapor Deposition, abbreviated PVD) process is required to deposit a titanium nitride (TiN) film on a wafer as an adhesion layer. In an existing process of depositing a titanium nitride film by a physical vapor deposition process, the wafer is placed on an electrostatic chuck in a process chamber, and a process gas is introduced into the chamber, and the process gas can form a plasma in the chamber The titanium target on the top of the cavity is bombarded, so that the target atoms are continuously deposited on the wafer, thereby forming a titanium nitride film on the wafer. In this process, in order to prevent the target atoms from being deposited on the inner peripheral wall of the cavity, a ring-shaped inner li...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C14/54C23C14/56C23C14/06

CPCC23C14/54C23C14/56C23C14/0641

Inventor 韩为鹏李强黄其伟邓斌

Owner BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com