Aromatic polyester resin moldings and process for production thereof

A technology for aromatic polyester and resin moldings, applied in the field of further improvement, can solve problems such as inability to obtain gas barrier properties and lower air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

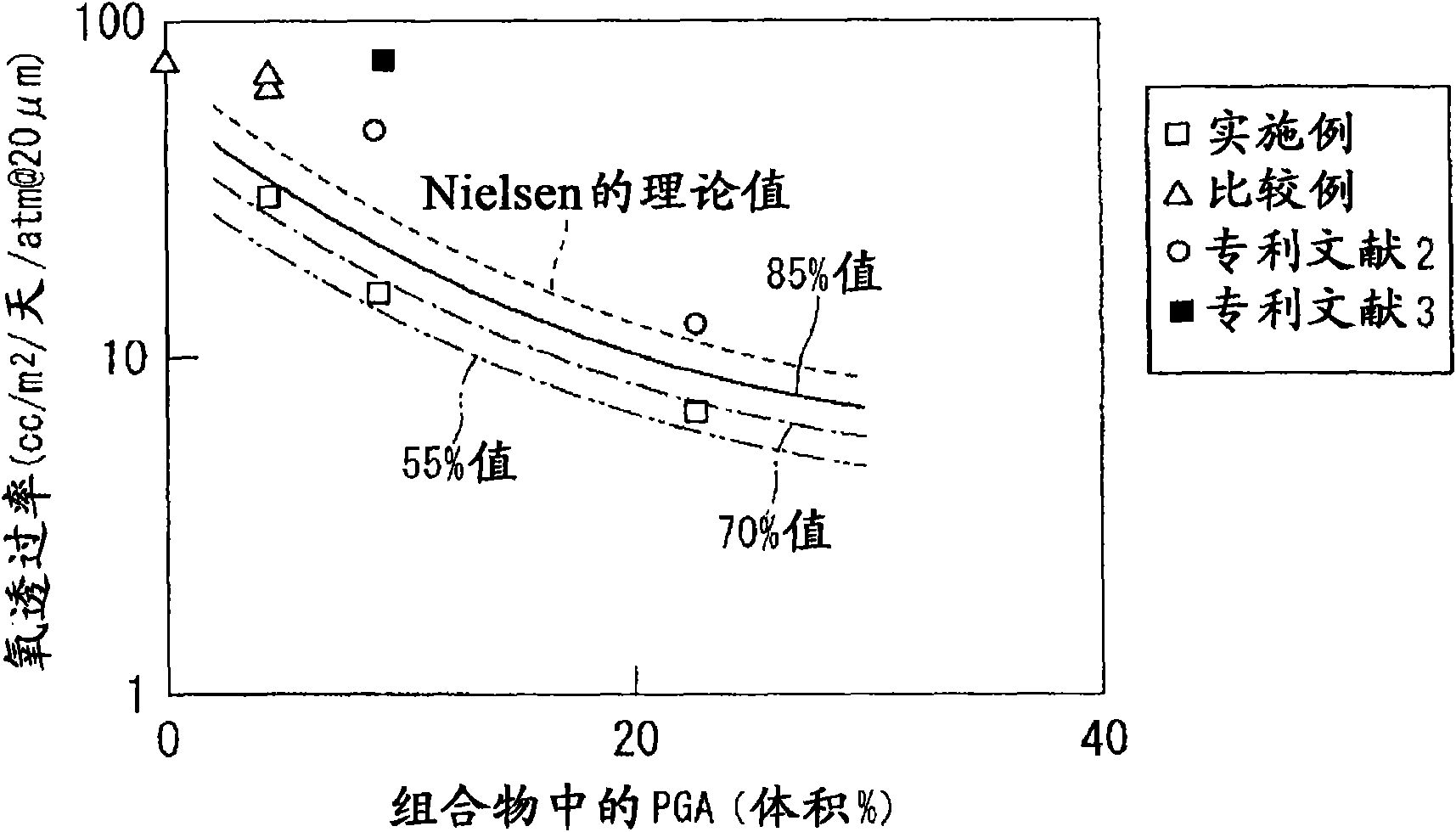

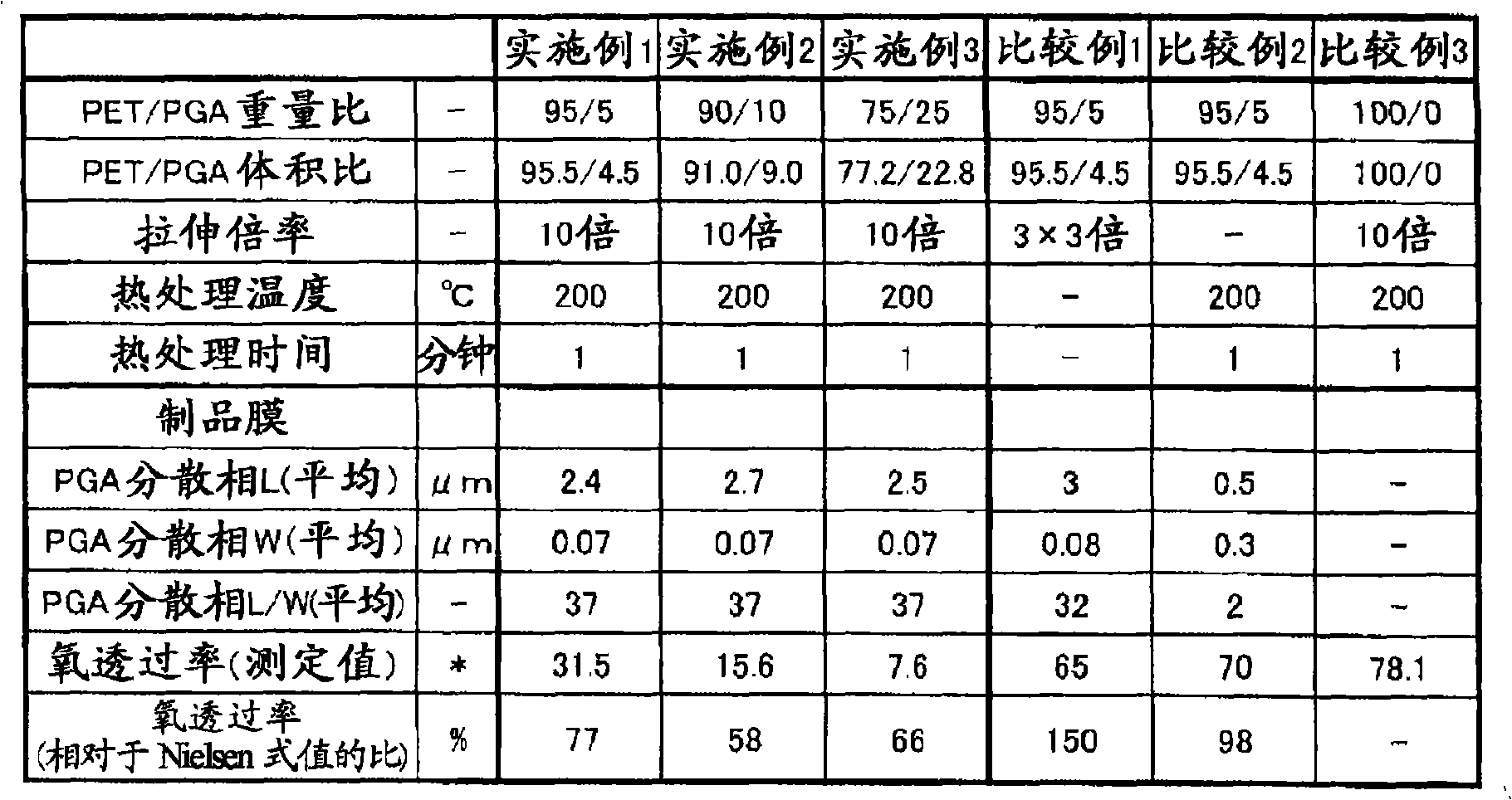

[0069] In a dry state, 95 parts by weight of polyethylene terephthalate (PET) flakes (manufactured by KoSa "1101") and 5 parts by weight of the above-mentioned PGA flakes were mixed in a dry state until they were uniform, and they were mixed with a Using a twin-screw extruder ("LT-20" from Toyo Seiki Co., Ltd.), melt processing was carried out under the conditions of a residence time in the extruder of 5 minutes to obtain pellets of the resin composition.

[0070] The obtained resin composition pellets were pinched between aluminum sheets, placed in a 270° C. hot press in this state, heated for 3 minutes, and then pressed at 5 MPa for 1 minute. Immediately thereafter, the mixture was transferred to a press machine in which water was circulated, and kept under pressure at 5 MPa for about 3 minutes to produce an amorphous compressed tablet.

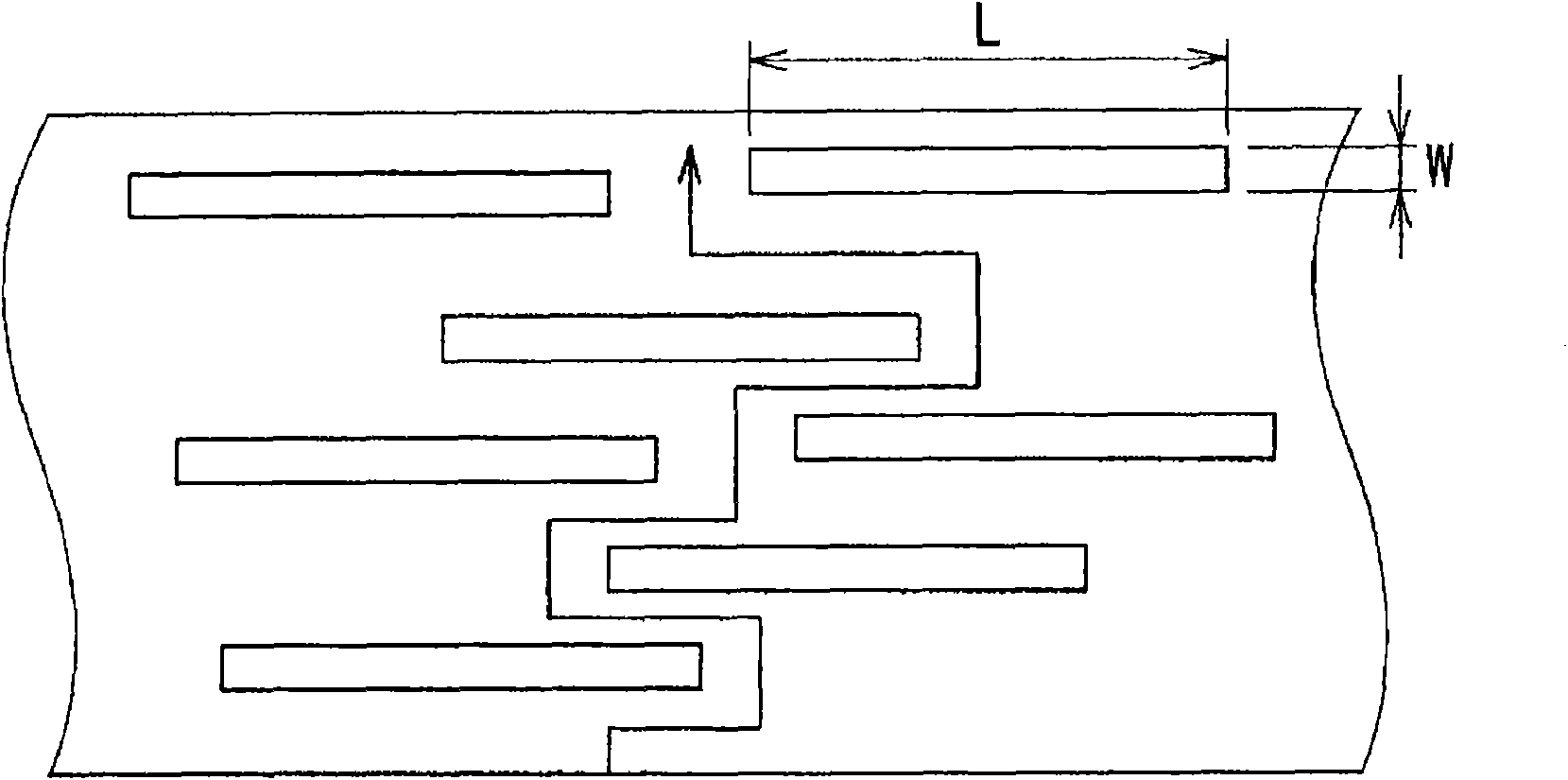

[0071] The obtained compressed sheet was fixed in a frame, held at 100° C. for 1 minute, and stretched by blow molding to a thickness of a...

Embodiment 2

[0078] A stretched and heat-treated film was produced in the same manner as in Example 1 except that the mixing ratio was changed to 90 parts by weight of PET flakes and 10 parts by weight of PGA flakes.

Embodiment 3

[0080] A stretched and heat-treated film was manufactured in the same manner as in Example 1 except that the mixing ratio was changed to 75 parts by weight of PET flakes and 25 parts by weight of PGA flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com