Aerostatic bearing spindles

A bearing and static technology, applied in the direction of air-cushion bearings, bearings, bearing components, etc., can solve the problems of influence, increase dynamic, bearing performance stiffness and unfavorable vibration reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

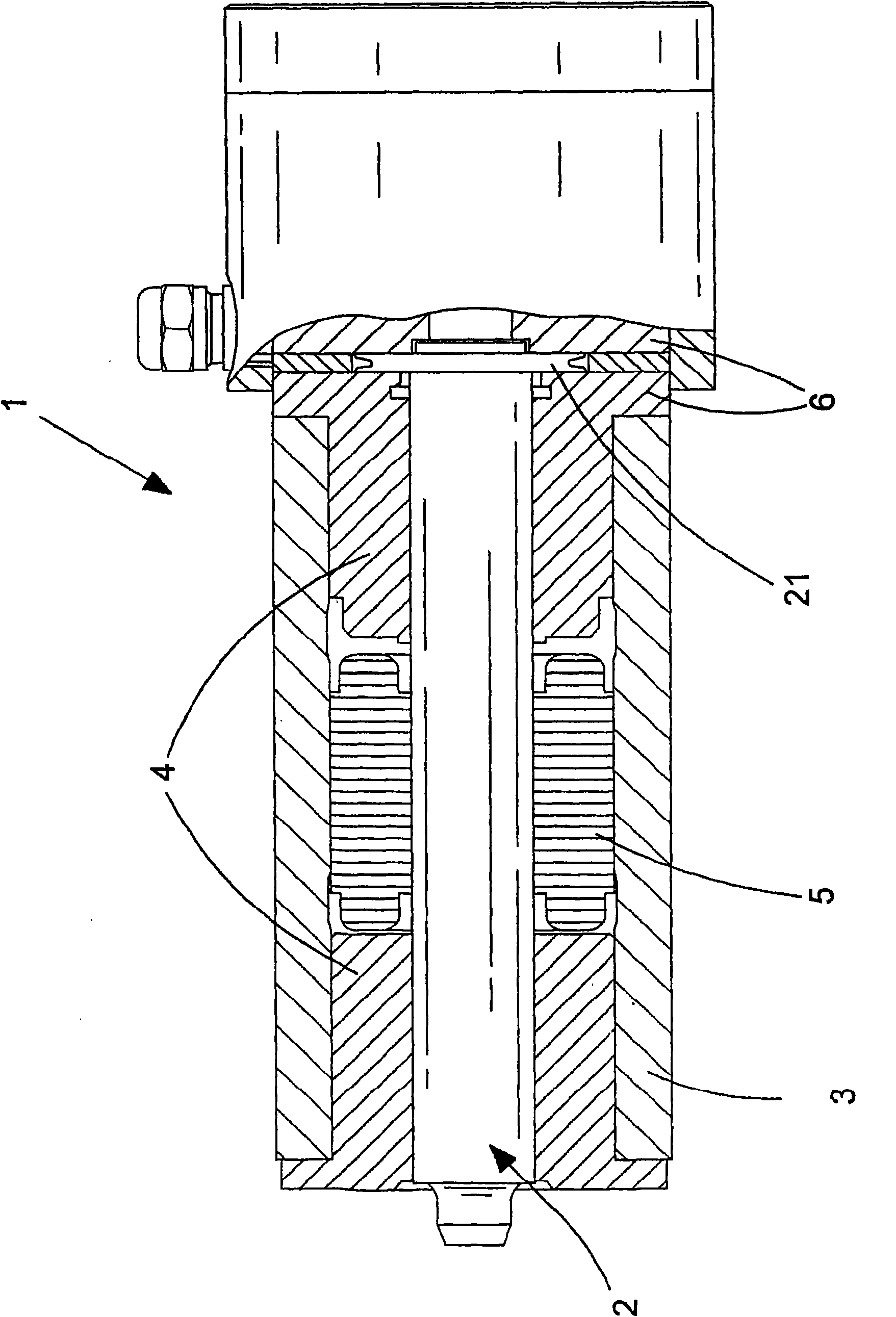

[0050] figure 1 There is shown a high speed pressurized aerostatic bearing spindle 1 arranged for a drilling machine and operating at speeds in excess of 50,000 rpm and up to about 300,000 rpm. The spindle comprises a shaft assembly 2 supported for rotation inside a body 3 by means of a pair of air bearings 4 . Between the pair of air bearings 4 is arranged an integral rotary motor 5 for driving the shaft assembly 2 in rotation relative to the remainder of the spindle. The structure and operation of the electric motor 5 is conventional in the field of aerostatic bearing drilling spindles, so it will not be described in more detail. A pair of opposed thrust bearings 6 are provided at one end of the spindle which sandwich a shaft runner 21 and provide axial positioning. A tool holder (not shown) is provided at the other end of the shaft assembly 2 for holding a tool, which in this embodiment is a drilling tool.

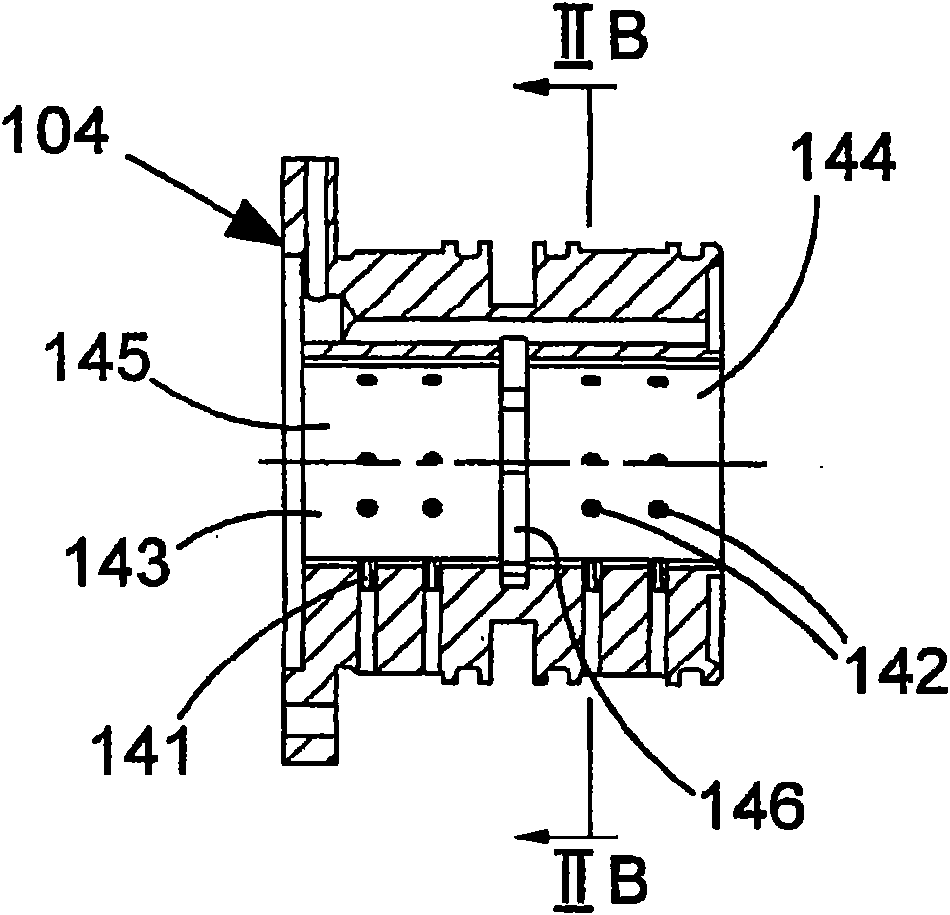

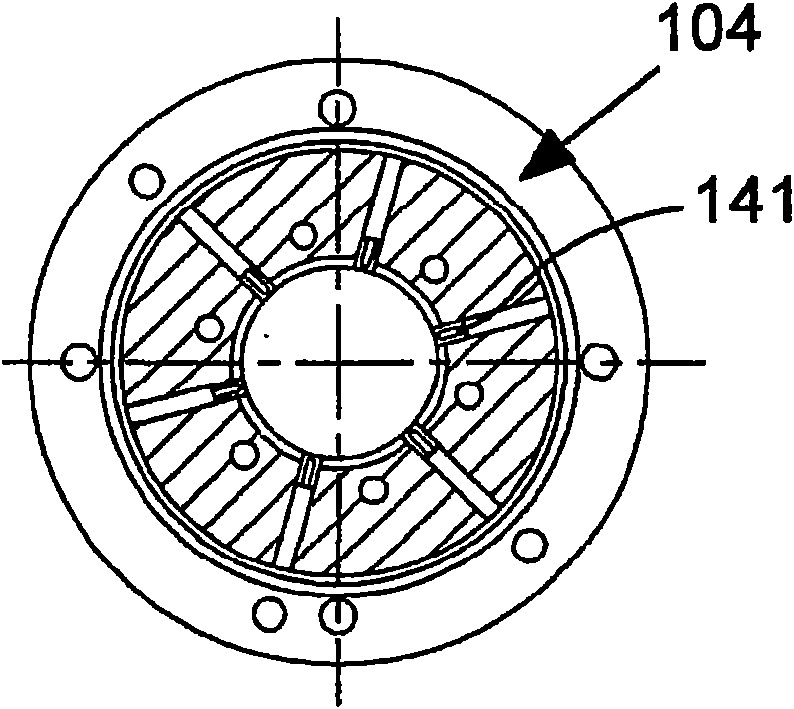

[0051] Figure 2A and 2B A conventional bearing 104 is shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com