heating cooker

A technology for cooking utensils and heating chambers, which is applied to cooking utensils, ohmic resistance heating, electric/magnetic/electromagnetic heating, etc., and can solve the problems of easy spillage and water spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

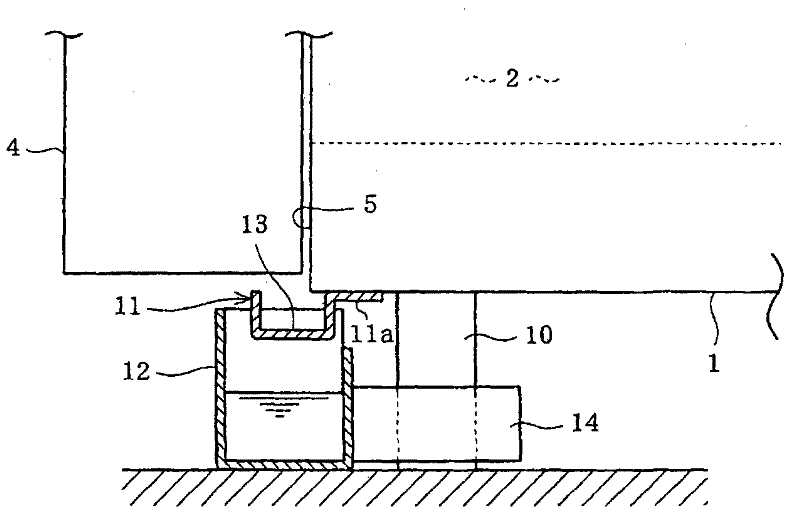

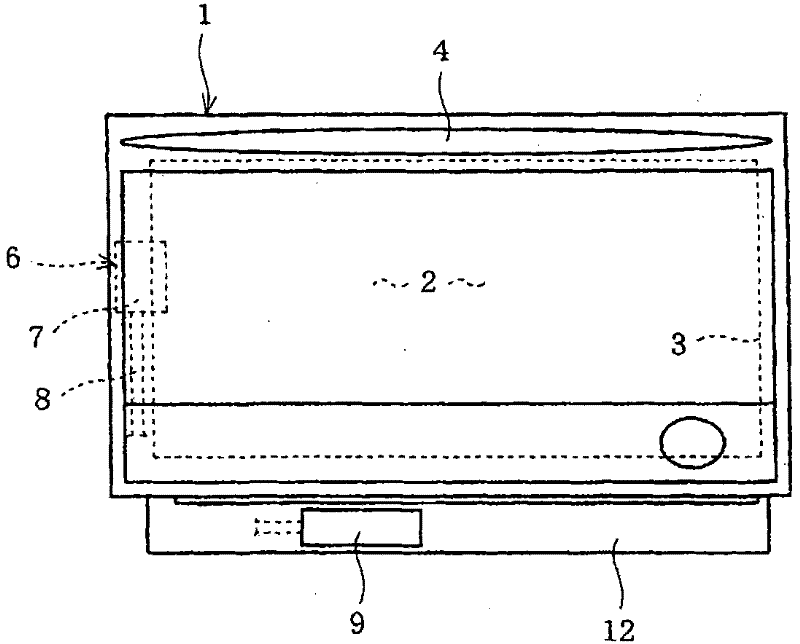

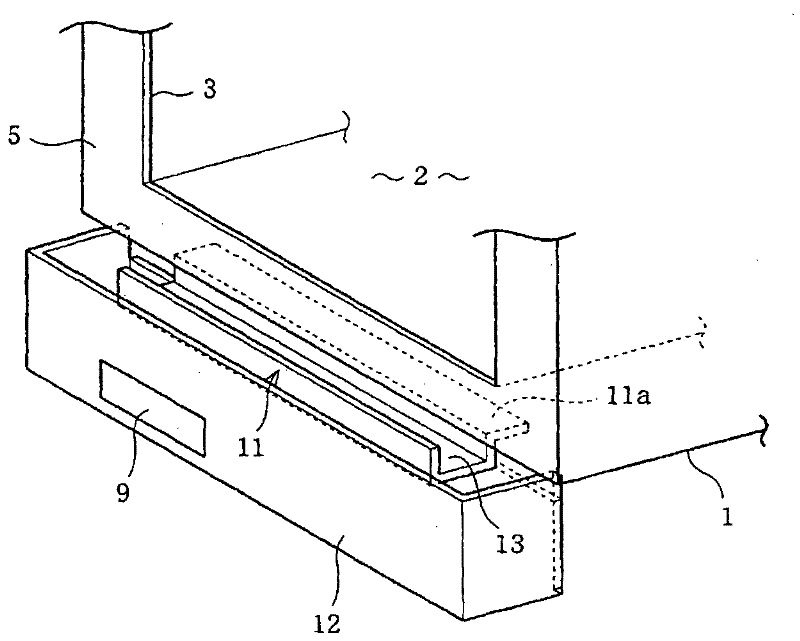

[0030] Hereinafter, regarding the heating cooker provided with the steam supply unit representing the first embodiment of the present invention, refer to Figure 1 ~ Figure 3 Be explained. in, figure 2 It is the front view of the whole heating cooker, figure 1 It is an enlarged side view showing the main part of the water drop countermeasure unit, image 3 It is an enlarged perspective view of the same essential part with the door removed.

[0031] This heat cooker is provided with a rectangular box-shaped main body 1 and a door 4. The main body 1 has a heating chamber 2 for heat-processing food inside. The operation part used for cooking setting is provided to be able to rotate in the front-back direction with the lower part as a fulcrum. Specifically, the door 4 is configured to be able to contact and separate from the front frame portion 5 around the opening portion 3 on its back side. In addition, at the four corners of the bottom of the main body 1, cylindrical leg ...

no. 2 Embodiment approach

[0046] Figure 4 and Figure 5 , representing the second embodiment of the present invention, Figure 4 is the part that has tank 9 etc. with figure 1 quite figure, Figure 5 It is an exploded perspective view showing a disassembled state of a main part. In this embodiment, with respect to the water tank 9 that constitutes the steam supply unit 6 described in the above-mentioned embodiments, specifically, a holding case 15 that can be detachably accommodated and held to hold the water tank 9 is provided, and in connection therewith, water droplets Improvement of countermeasures.

[0047] That is, the water tank 9 has a detachable box-shaped structure penetrating through the center of the second water receiving part 16 similarly to the above-mentioned embodiment, and a handle part 9a is provided at the front end. And the 2nd water receiving part 16 made of resin, especially from Figure 5 It can be clearly seen that a wide water storage space extending to the rear is form...

no. 3 Embodiment approach

[0054] Figure 6 , which represents the essence of the third embodiment of the present invention and figure 1 equivalent diagrams showing the composition with additional partial sections, and Figure 7 is the same as that showing its modification figure 1 Quite a graph. In this embodiment, a water drop countermeasure that can also cope with the different dripping states of water droplets leaking out of the main body 1 is implemented.

[0055] First, regarding the Figure 6 The composition is explained. The bottom plate 2a constituting the bottom of the heating chamber 2 included in the main body 1 and the bottom plate 1a constituting the bottom of the main body 1 are integrally welded to the front frame portion 5 at the front, thus forming a heating system having an opening 3 at the front. Chamber 2 for body 1. Moreover, the first water receiving portion 21 is fixed under the bottom plate 1a as the outer bottom of the main body 1, so far it is the same as that of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com