Distribution device applied to thick plaster slurry

A distribution device and thick slurry technology, which is applied in the field of wet flue gas desulfurization, can solve the problems of complex pipeline system layout, easy deposition and blockage of equipment pipelines, etc., and achieve the effects of reducing failure points, reducing power consumption, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

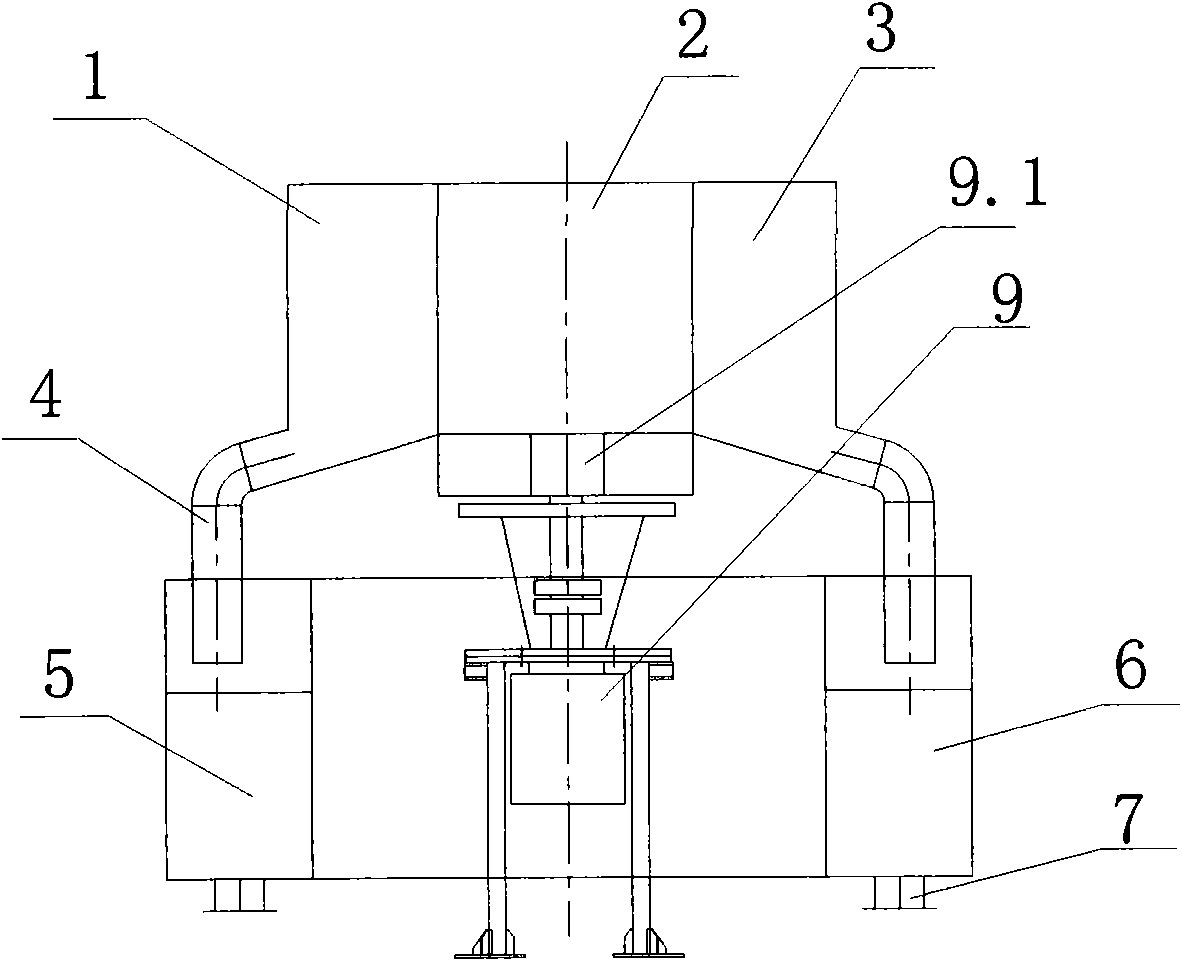

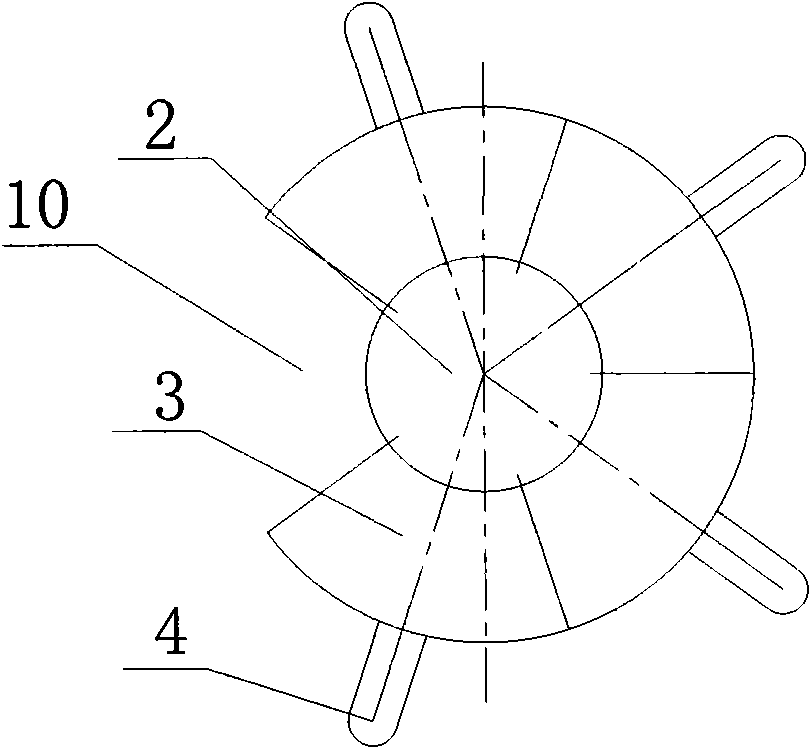

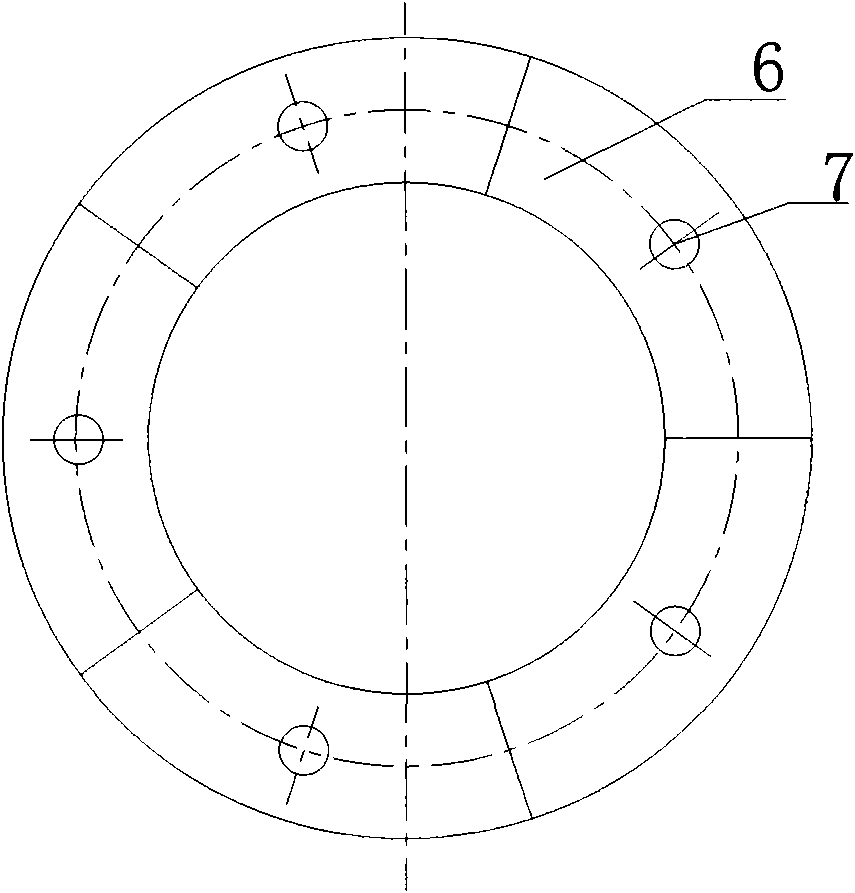

[0022] see Figure 1 to Figure 4 , the present invention includes a top flow distributor 1, an annular bottom flow distribution box 5 and a vertical drive mechanism 9. The top flow distributor 1 is composed of a central cylinder 2, a plurality of compartments 3 and gaps 10 communicating with the central cylinder 2, and a movable inserting plate 8 is provided at the connection between each compartment 3 and the central cylinder 2. The numbers of the compartments 3 and the gaps 10 are respectively the same as the number of operating units and the number of spare units of the vacuum belt dehydrator. The bottom plane of the central cylinder 2 of the top flow distributor 1 is supported on the bearing 9.1 at the top of the driving mechanism 9 and makes the top flow distributor 1 rotate under the driving state. The outlet at the bottom of the bottom plane of each compartment 3 is connected with a downwardly curved slurry distribution pipe 4 facing the underflow distribution box 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com