Synchronous lifting mechanism

A technology of synchronous lifting and lifting of screw, applied in auxiliary devices, gas flame welding equipment, plasma welding equipment, etc., can solve the problems of poor synchronization, high cost, easy to produce tilt, etc., to control the failure rate and wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

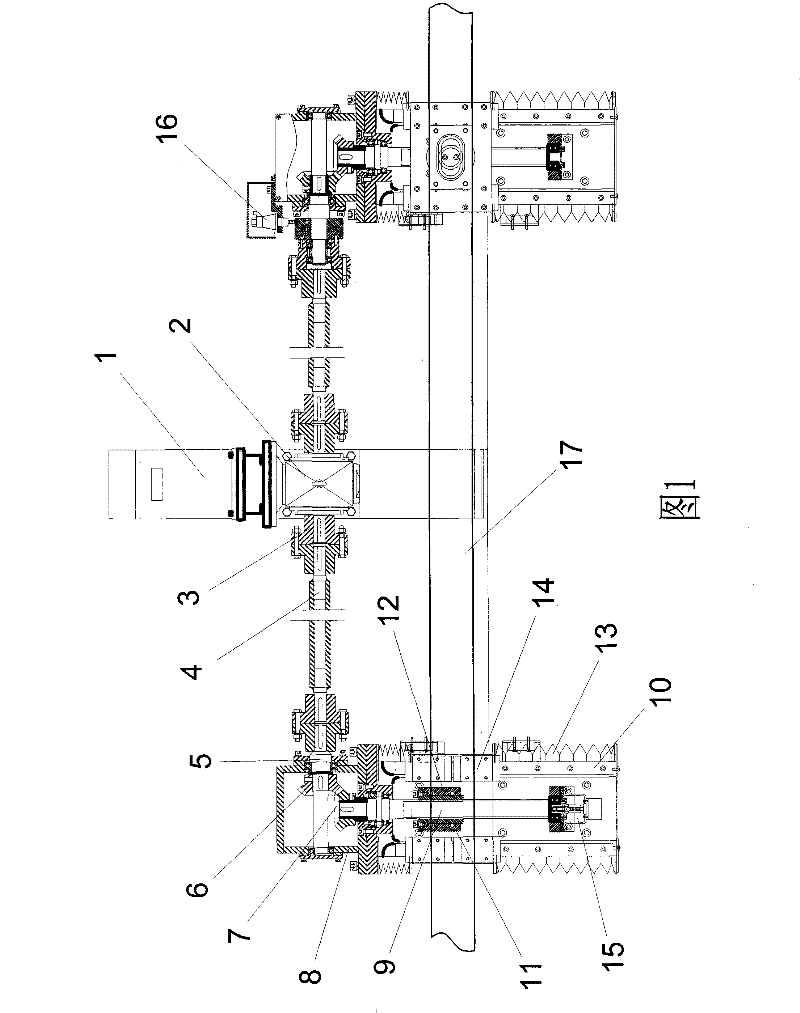

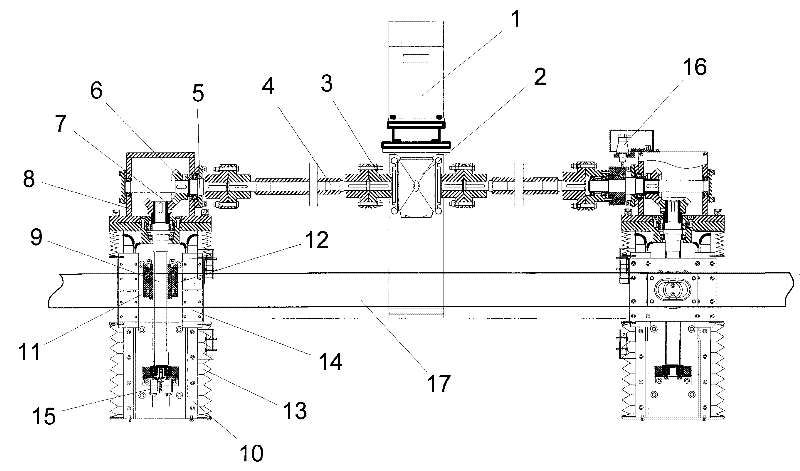

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] Such as figure 1 As shown: the synchronous lifting mechanism includes the active part, left and right driven parts, left and right connecting parts, encoder 15 and clutch 16; the left end of the driving part is connected with the left driven part by the left connecting part, and the encoder 15 is installed on the left driven part; Active part right end is connected with clutch 16 left ends with the right connecting part, and clutch 16 right ends are connected with right driven part.

[0014] The active part includes a DC motor 1 and a double-output shaft reducer 2 connected thereto. The DC motor 1 is used as a power output source and is bidirectionally driven by the double-output shaft reducer 2; the left and right connecting parts have the same structure, including a joint Shaft device 3 and connecting rod 4, shaft coupling 3 and connecting rod 4 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com