Normal temperature compound desulfuration and dearsenization agent and preparation method thereof

A technology for desulfurization, dearsenic, and carrier, which is used in the refining of hydrocarbon oil, refining with metal oxides, and the petroleum industry. and other problems to achieve the effect of reducing pollution and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

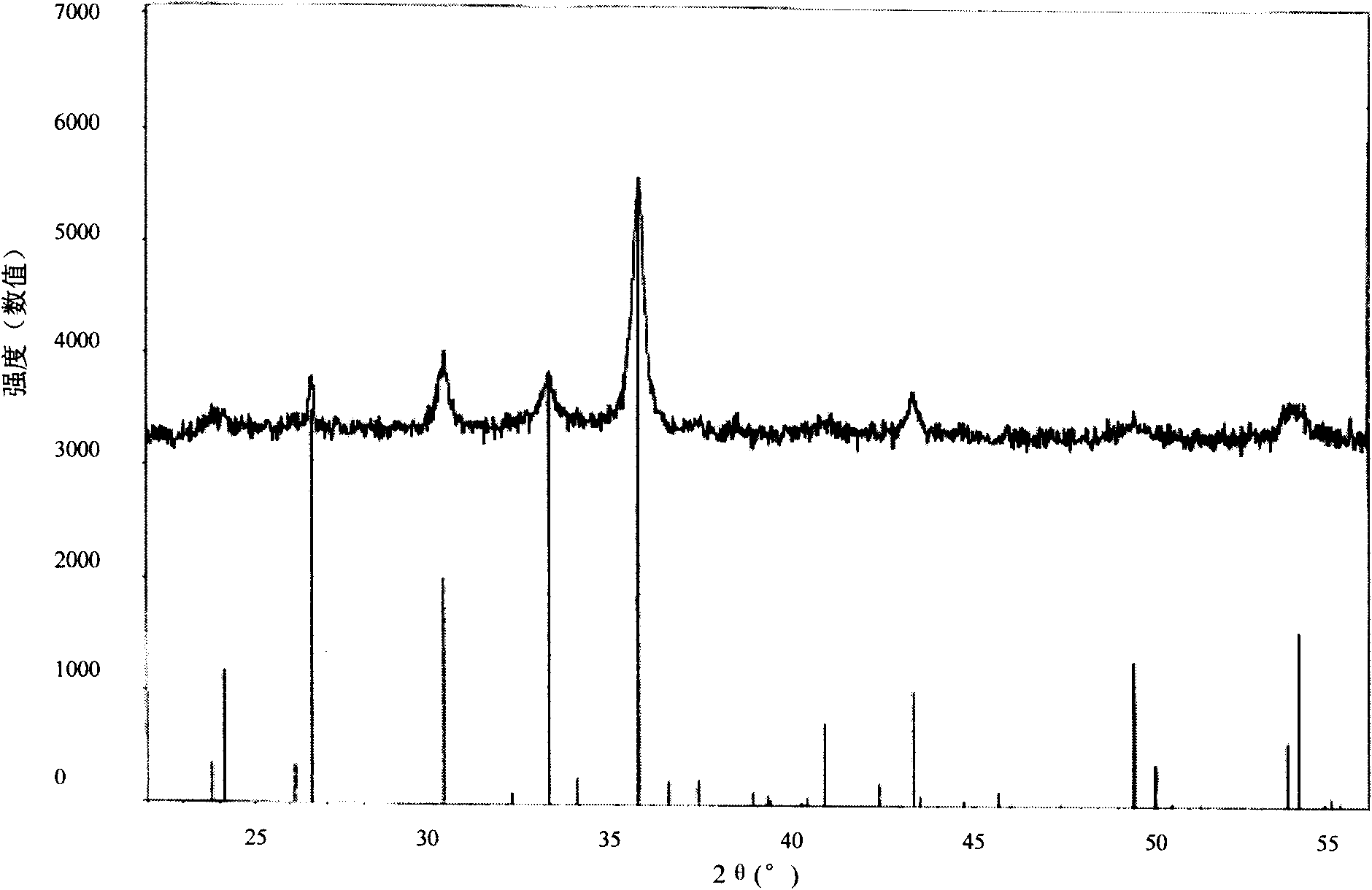

Image

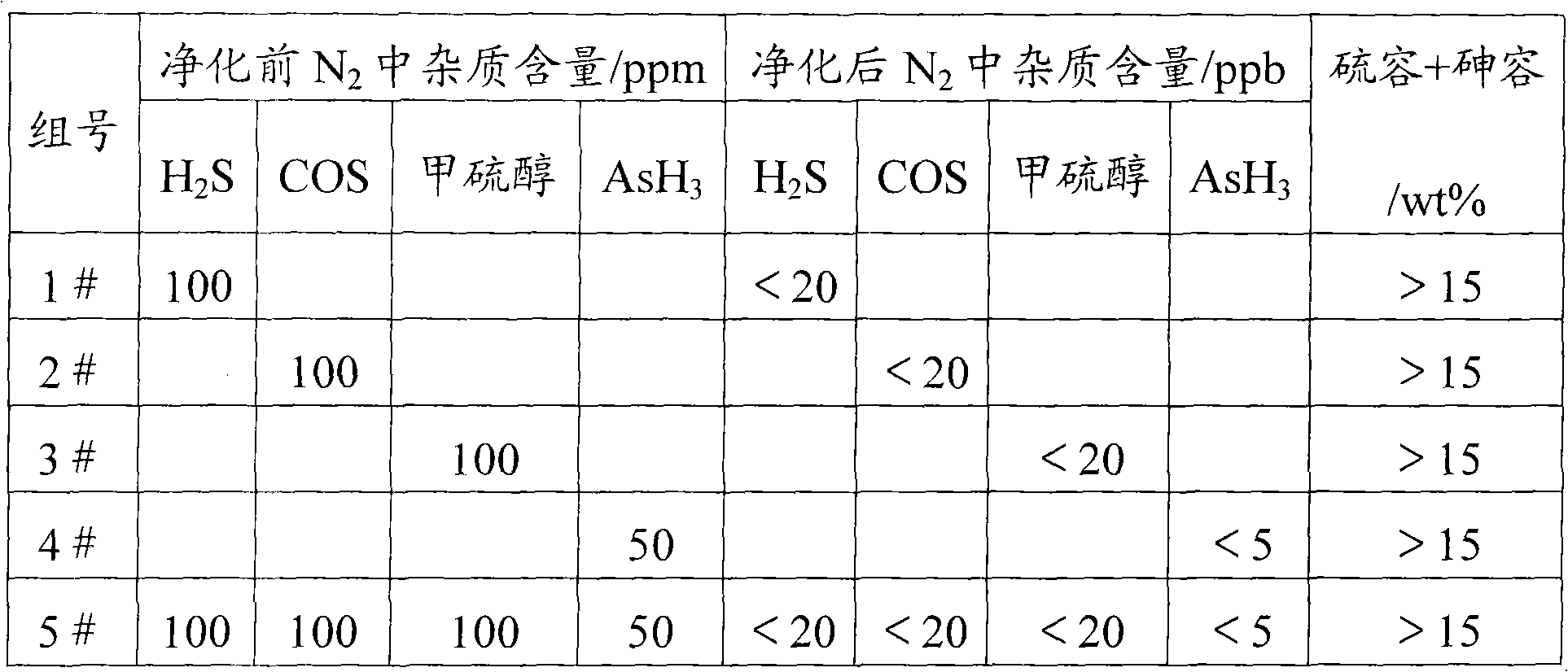

Examples

Embodiment 1

[0027] Choose 80 mesh, specific surface area is 300m 2 / g, the pore volume is 10cm 3 / g microspheres γ-Al 2 o 3 Carrier 9.9g is put into the lead acetate solution (Pb(Ac) of 100ml 0.89mol / L 2 ·3H 2 (2) in, immerse 3 hours and make active lead acetate solution fully enter microsphere carrier inside; Because the amount of impregnating liquid is selected according to the absorption rate of carrier to active component, so described active component impregnating liquid can one-time immerse Inside the microsphere carrier, no lead acetate waste liquid will remain. After the impregnating solution is completely immersed in the carrier, the carrier is taken out and dried at 100°C for 5 hours to remove the moisture in the carrier; then the dried γ-Al loaded with lead acetate 2 o 3 The carrier is activated by roasting at 400°C for 10 hours under aerobic conditions, so that the lead acetate solution is decomposed, and then the γ-Al loaded with PbO active components is obtained. 2 o ...

Embodiment 2

[0031] Select 60 mesh, specific surface area is 20m 2 / g, the pore volume is 0.1cm 3 / g microspheres γ-Al 2 o 3 Carrier 0.066g is put into the lead acetate solution (Pb(Ac) of 1000ml0.18mol / L 2 ·3H 2 (2) in, immerse 1 hour and make active lead acetate solution fully enter the inside of microsphere carrier; Because the amount of soaking liquid is calculated and selected according to the absorption rate of carrier to active component, so described active component soaking liquid can one-time immerse Inside the microsphere carrier, no lead acetate waste liquid will remain. After the impregnating solution is completely immersed in the carrier, the carrier is taken out and dried at 120°C for 1 hour under aerobic conditions to remove the moisture in the carrier; then the dried γ-Al loaded with lead acetate 2 o 3 The carrier is activated by roasting at 650°C for 5 hours under aerobic conditions to decompose lead acetate, and then obtain γ-Al loaded with PbO active components 2...

Embodiment 3

[0035] Select 120 mesh, specific surface area is 350m 2 / g, the pore volume is 20cm 3 3g of activated carbon / g is put into 100ml 0.893mol / L lead acetate solution (Pb(Ac) 2 ·3H 2 (2), immerse 2.5 hours to make the active lead acetate solution fully enter the inside of the microsphere carrier; because the amount of the impregnating liquid is selected according to the absorption rate of the carrier to the active component, so the active component impregnating liquid can be immersed in one time. Inside the microsphere carrier, no lead acetate waste liquid will remain. After the impregnating liquid is completely immersed in the carrier, take out the carrier and dry it at 110°C for 2.5 hours to remove the moisture in the carrier; then roast the dried activated carbon loaded with lead acetate under aerobic conditions at 500°C After 8 hours of activation, the lead acetate is decomposed, and then an activated carbon carrier loaded with PbO active components is obtained. In the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com