Alignment method of shooting line and object moving direction based on linear array CCD camera velocity measurement

A technology of object movement and direction of movement, applied in radio wave measurement systems, devices used to measure the time required to move a certain distance, re-radiation of electromagnetic waves, etc., can solve problems such as inaccurate CCD speed measurement and cloth deviation from the direction of movement, etc., to achieve High measurement accuracy, improved speed measurement accuracy, and the effect of maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

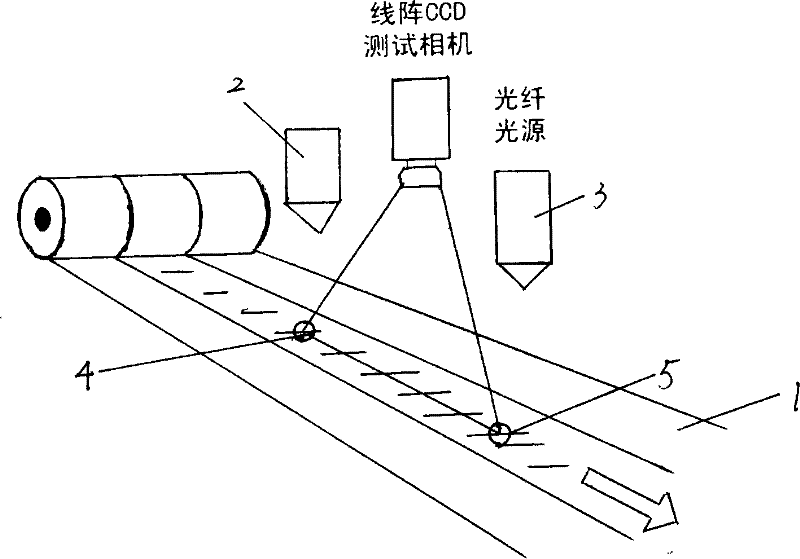

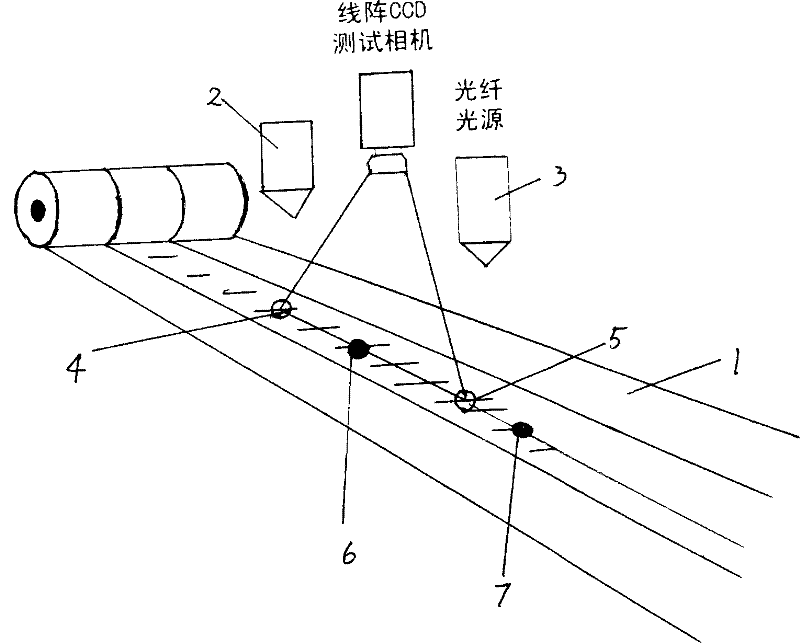

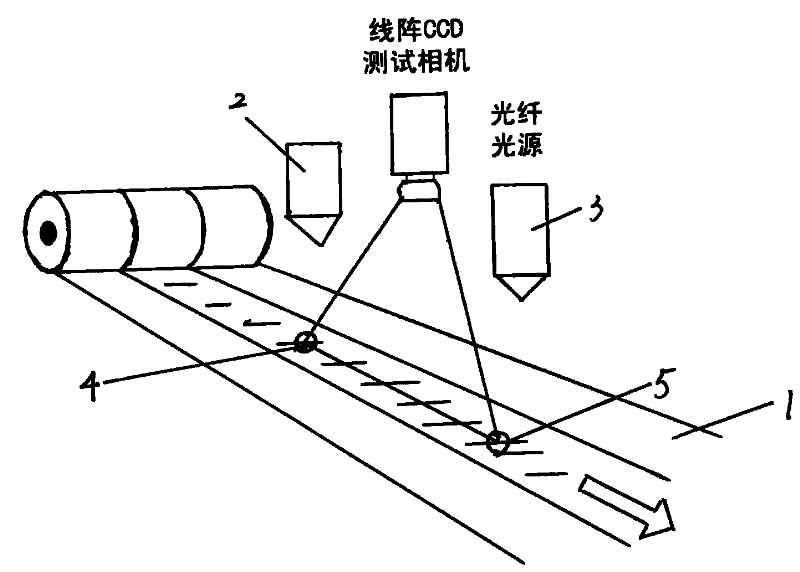

[0033] A method for aligning a shooting line with a moving direction of an object based on a linear array CCD camera speed measurement, comprising the following contents:

[0034] (1), above the fast-moving object (cloth) 1, in the direction of motion of the object, set a linear array CCD speed measuring camera, with the front and rear two point light sources 2, 3, and the front and rear two point light sources 2, 3 Irradiate on the surface of the object to produce front and rear light spots 4, 5; the linear array CCD speed measuring camera takes an image of the object surface at a certain moment, the image contains the front and rear light spot images, and the front and rear light spot images respectively contain corresponding to The surface information of the first object 6 and the surface information of the second object 7 at the positions of the front and rear light spots;

[0035] (2), according to the distance between the front and rear light spots produced by the two po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com