Vertical current transformer

A current transformer, upright and vertical technology, applied in the field of upright and vertical current transformers, can solve the problems that affect the use effect of the current transformer, the welding end is easy to produce tip discharge, and the electric field is unevenly distributed, so as to achieve beauty, practicality and promotion value, reduced tip discharge, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

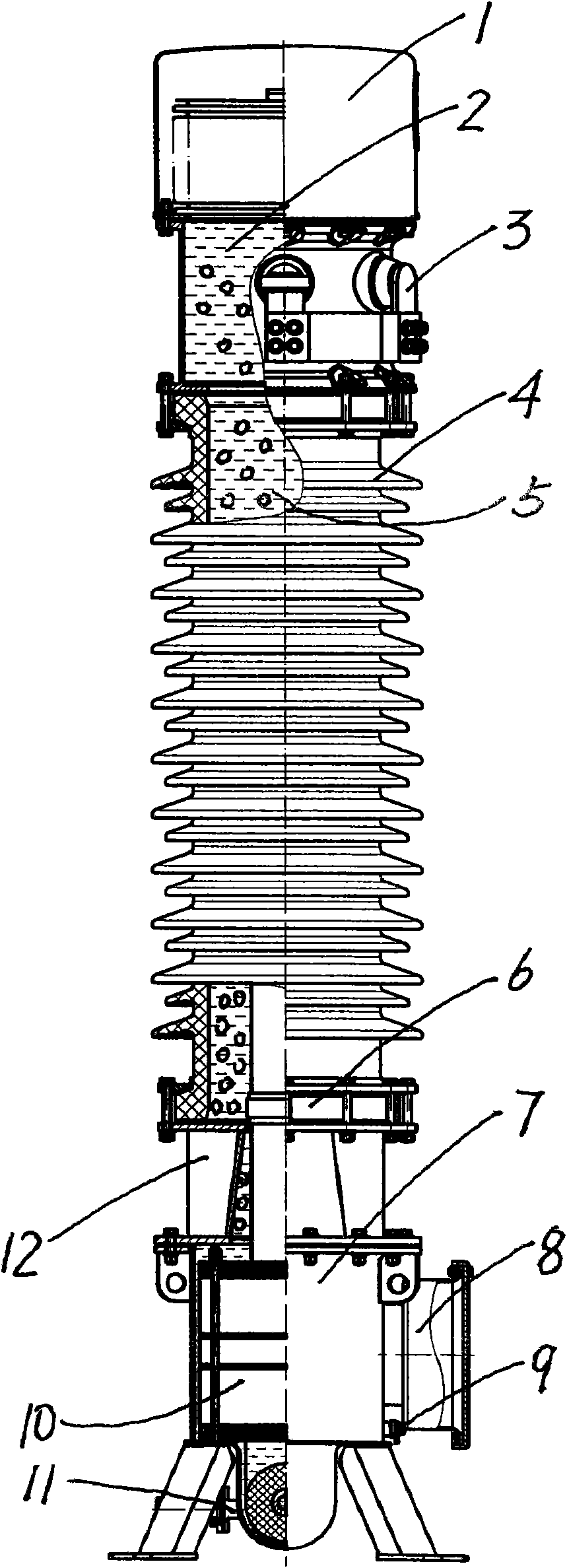

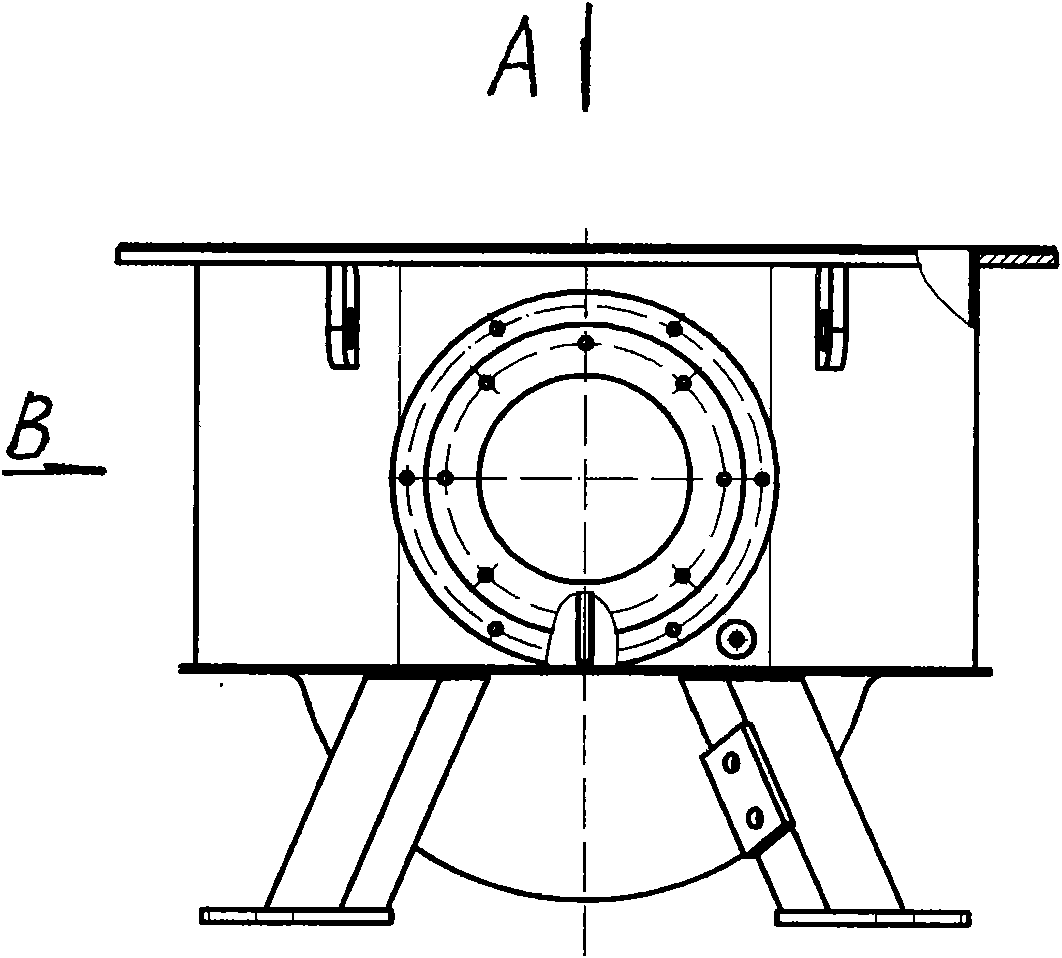

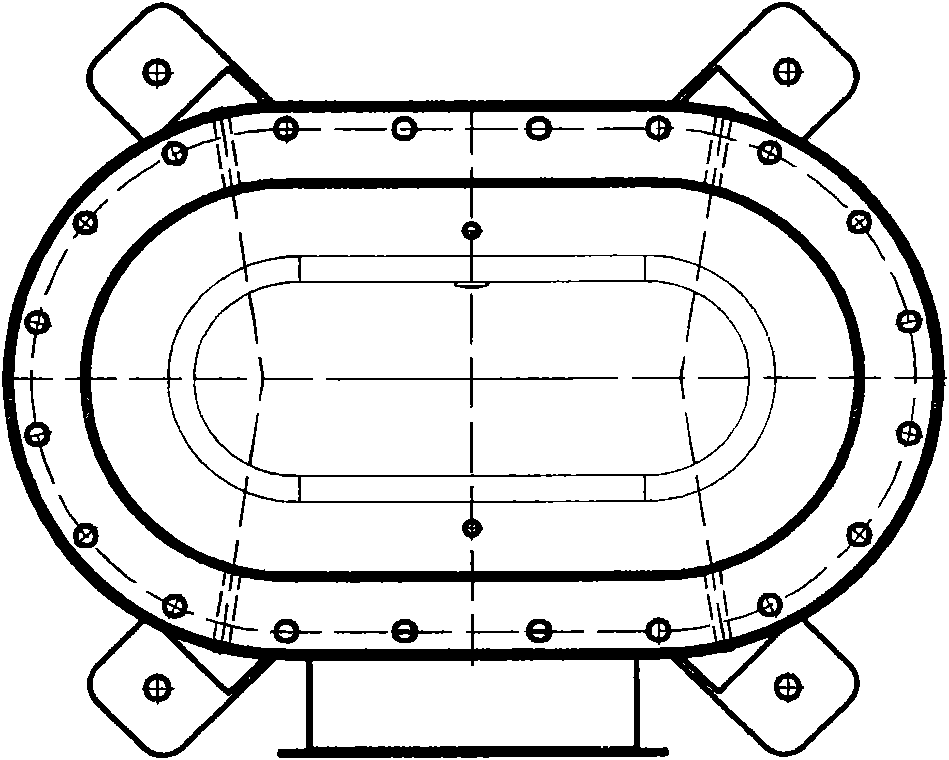

[0017] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , an upright current transformer of the present invention, comprising an expander 1, an oil conservator 2, a primary conductive row 3, a bushing 4, an insulating medium 5, a lower hoop 6, a fuel tank shell 7, an outlet box 8, Grounding bolt 9, secondary winding 10, oil drain valve 11, fuel tank loam cake 12, oil tank loam cake 12 is sealed and fixed on the fuel tank shell 7, and lower hoop 6 is sealed and fixed on the fuel tank loam cake 12, and the lower A casing 4 is arranged on the hoop 6, and an oil conservator 2 is connected to the casing 4, and an expander 1 is arranged on the oil conservator 2, and a primary conductive bar 3 is arranged on the oil conservator 2, and through the conductive rod It is connected with the secondary winding 10, the outlet box 8 is connected with the fuel tank shell 7, the outlet box 8 is connected with the secondary winding 10, an oil discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com