Active matrix display compensating method

A voltage source and source electrode technology, applied in the field of active matrix display devices, can solve the problems of reducing the aperture ratio and unusable bottom light-emitting devices, and achieve the effect of increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

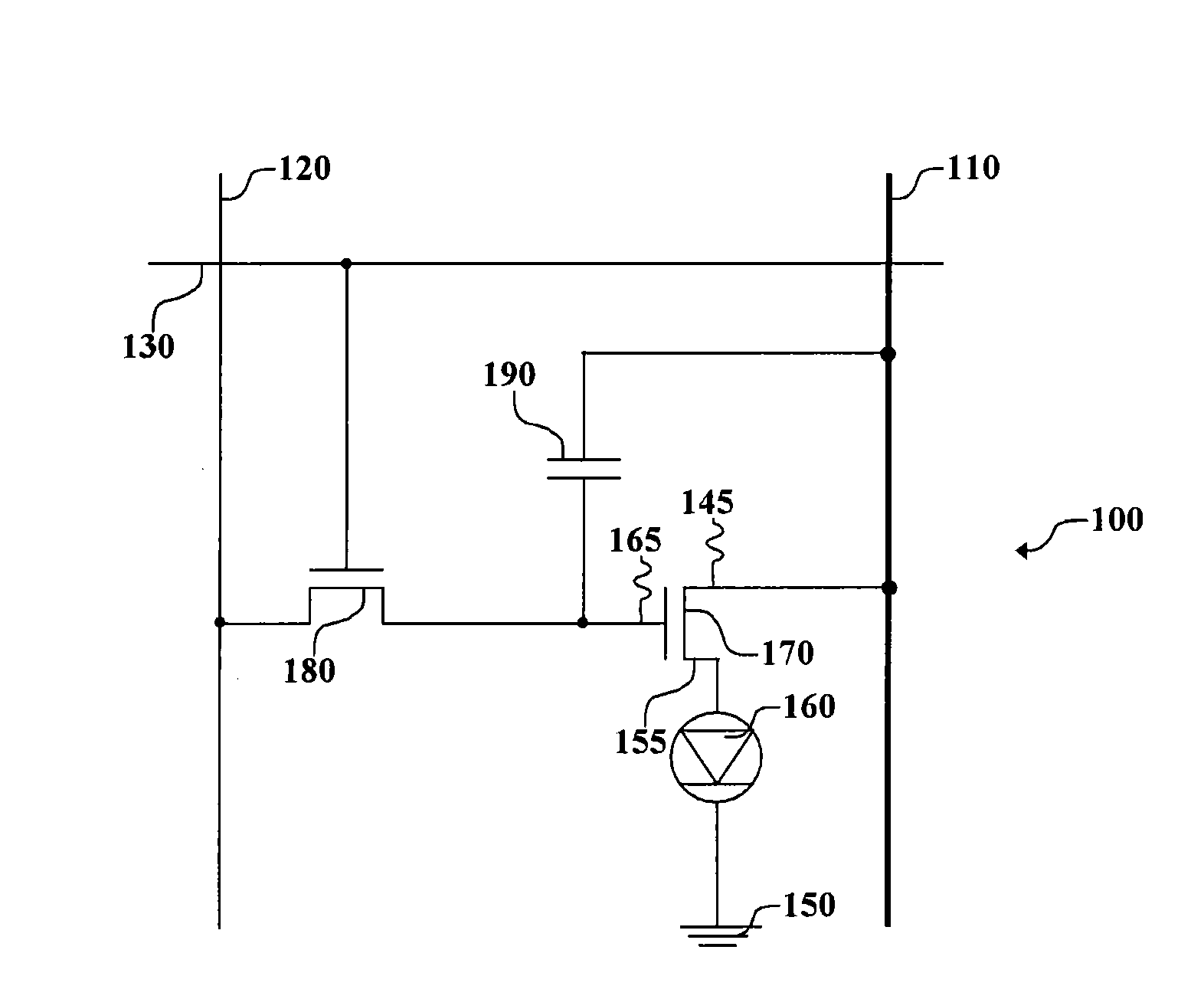

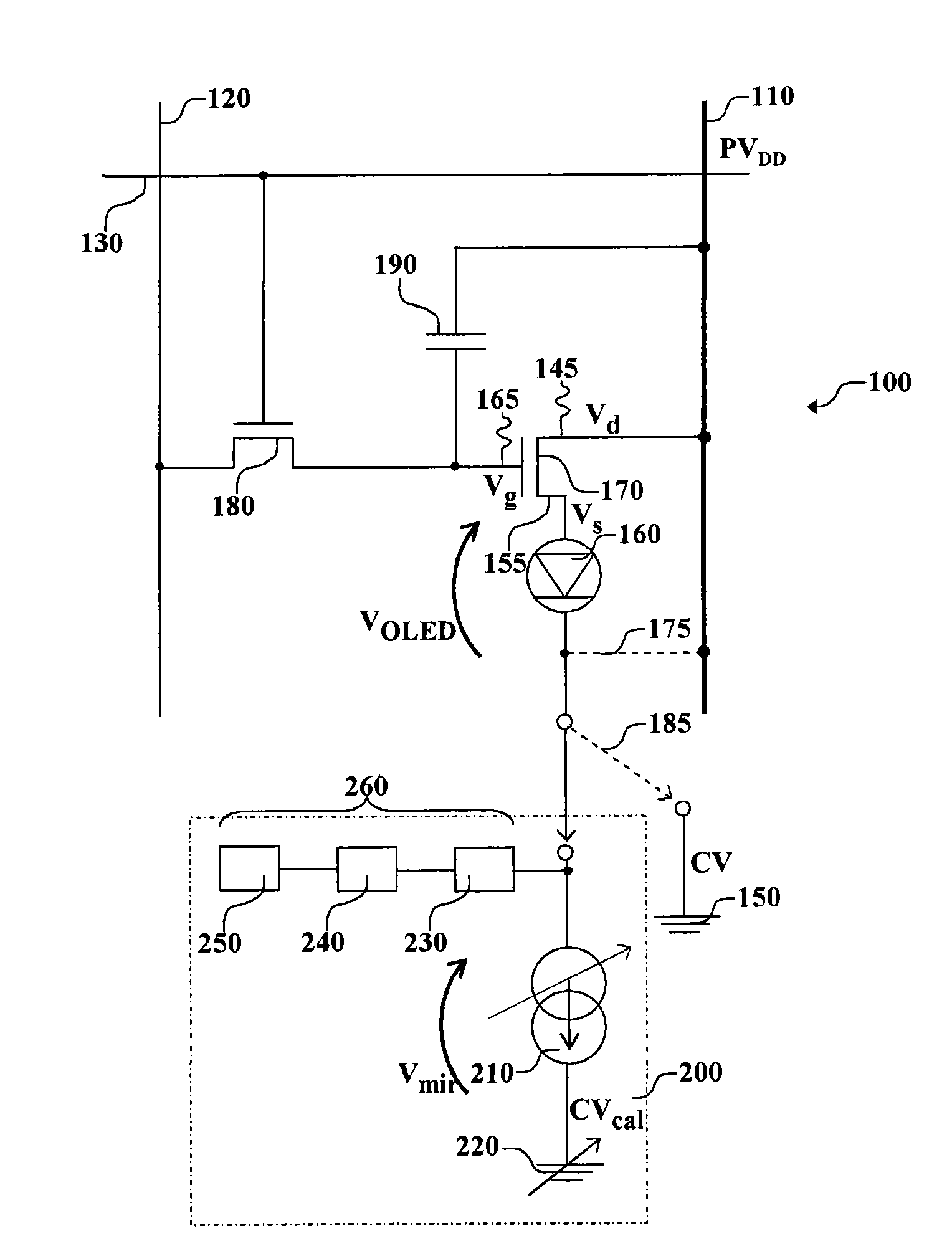

[0020] now go to figure 1 , shows a schematic diagram of one embodiment of an OLED driving circuit that can be used in the practice of the present invention. Such OLED driver circuits are well known in the technical field of active matrix OLED displays. OLED pixel drive circuit 100 has data line 120, supply line or first voltage source 110, select line 130, drive transistor 170, switching transistor 180, OLED device 160, which may be a single pixel of an OLED display, and capacitor 190. The driving transistor 170 is an amorphous silicon (a-Si) transistor and has a first electrode 145 , a second electrode 155 and a gate electrode 165 . The first electrode 145 of the drive transistor 170 is electrically connected to the first voltage source 110 , and the second electrode 155 is electrically connected to the OLED device 160 . In this embodiment of the pixel driving circuit 100, the first electrode 145 of the driving transistor 170 is a drain electrode, and the second electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com