Airplane trailing edge flap retracting mechanism

A technology of trailing edge flaps and retractable mechanisms, applied in wing adjustment, aircraft parts, aircraft control, etc., can solve the problems of aircraft performance degradation, flap span displacement, etc., and achieve light weight, small size, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

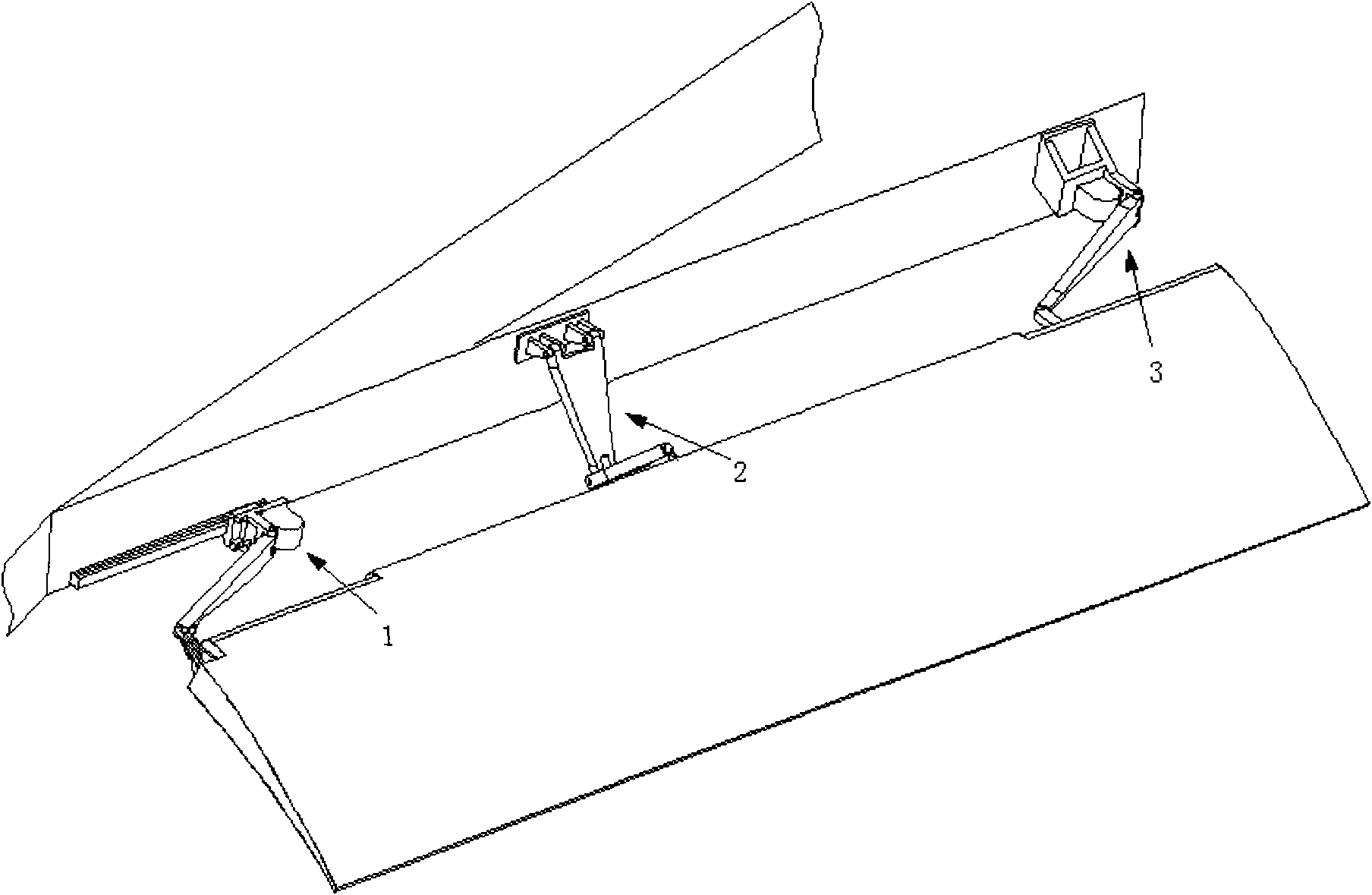

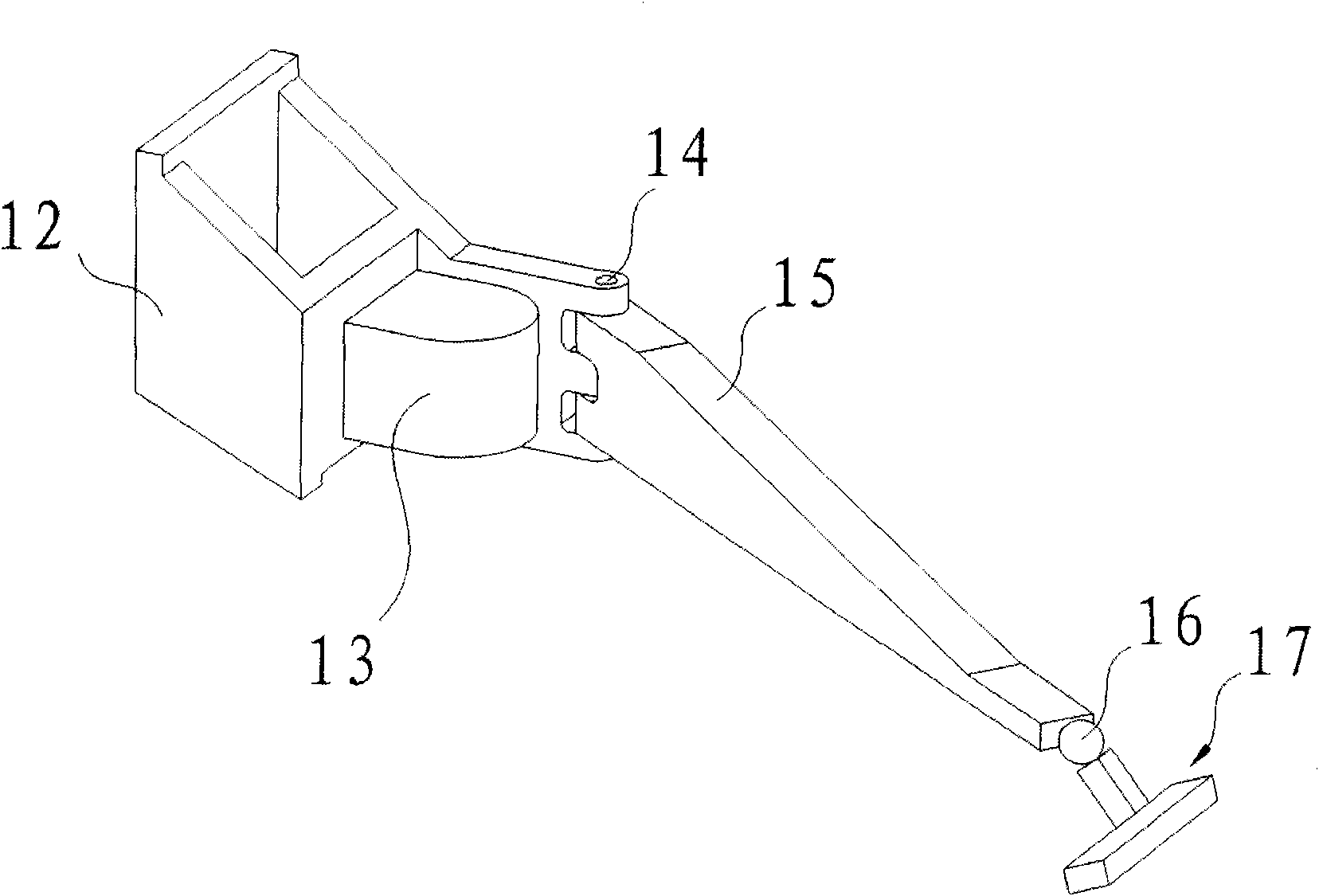

[0013] The present invention will be described in further detail below. see Figure 1~4 , an aircraft trailing edge flap retractable mechanism, comprising wing rear beams and flap leading edge stringers, is characterized in that there is an outer rocker assembly 1, a spanwise constraint rocker assembly 2 and an inner rocker assembly 3. The above three rocker arm components are respectively connected with the wing rear spar and the leading edge stringer of the flap to form the aircraft trailing edge flap retractable mechanism;

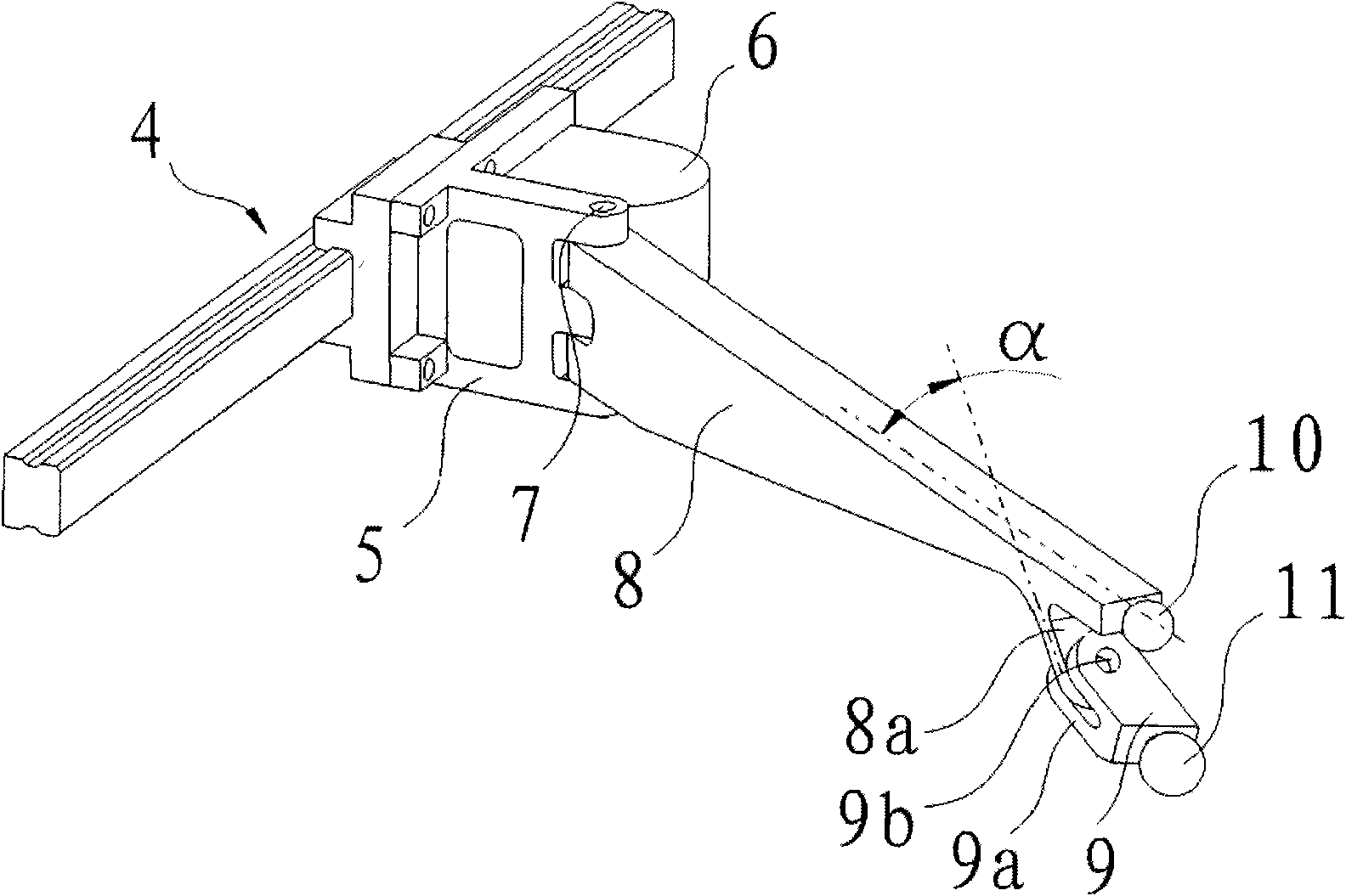

[0014] (1) The outer rocker arm assembly 1 consists of the first guide rail slider mechanism 4, the outer rocker arm support 5, the first drive motor 6 with a deceleration mechanism, the outer rocker arm shaft 7, the outer rocker arm 8, the control arm 9, the first A spherical hinge 10 and a second spherical hinge 11 are formed; the guide rail of the first guide rail slider mechanism 4 is fixed on the position corresponding to the outer end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com