Preparation method and device for seabed natural gas hydrate

A hydrate and natural gas technology, applied in the direction of gas fuel, petroleum industry, solid fuel, etc., can solve the problems of low diffusion coefficient of dense hydrate layer, long hydrate formation time, uneven distribution of hydrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method (abbreviated test method) for simulating the diffusion and migration of seabed natural gas to form hydrates, the steps are as follows:

[0049] 1) Installation of the sample: dry the soil sample, and put a certain amount of soil sample into the high-pressure reaction vessel A.

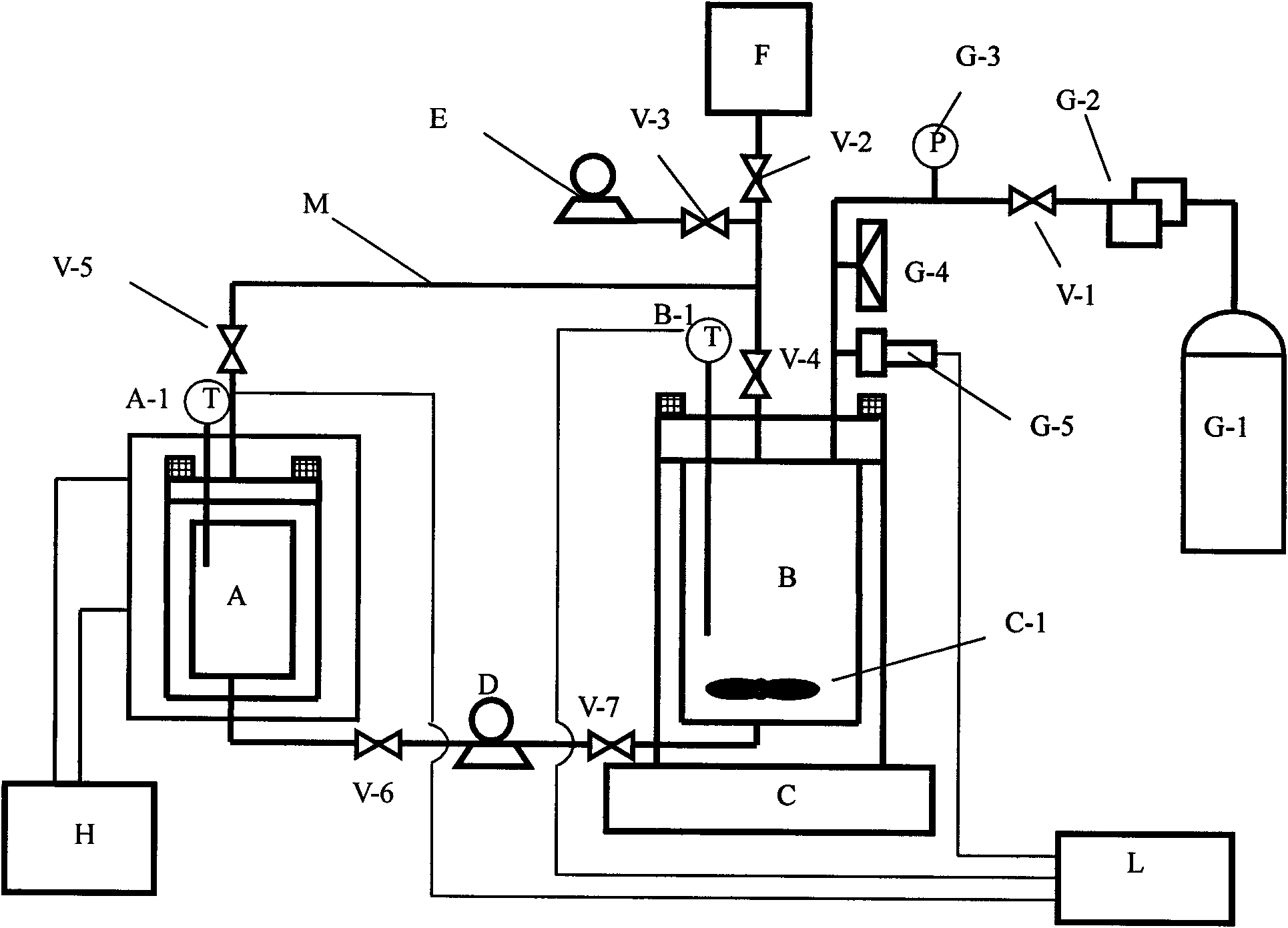

[0050] 2) Check the airtightness of the system: close the second and third valves V-2 and V-3, open all other valves, vent nitrogen to 6-8mpa, close the first valve V-1, wait for 3-4 hours, If the gas pressure in the system remains constant, the airtightness of the system is intact.

[0051] 3) Vacuuming: close the first and second valves V-1 and V-2, and open all other first, second, third, fourth, fifth, sixth and seventh valves V-1 and V- 2. For V-3, V-4, V-5, V-6, and V-7, turn on the vacuum pump E to pump air for 15 minutes to 30 minutes. Close the third valve V-3.

[0052] 4) Water injection saturation: open the second valve V-2 and use the water supply tank F to in...

Embodiment 2

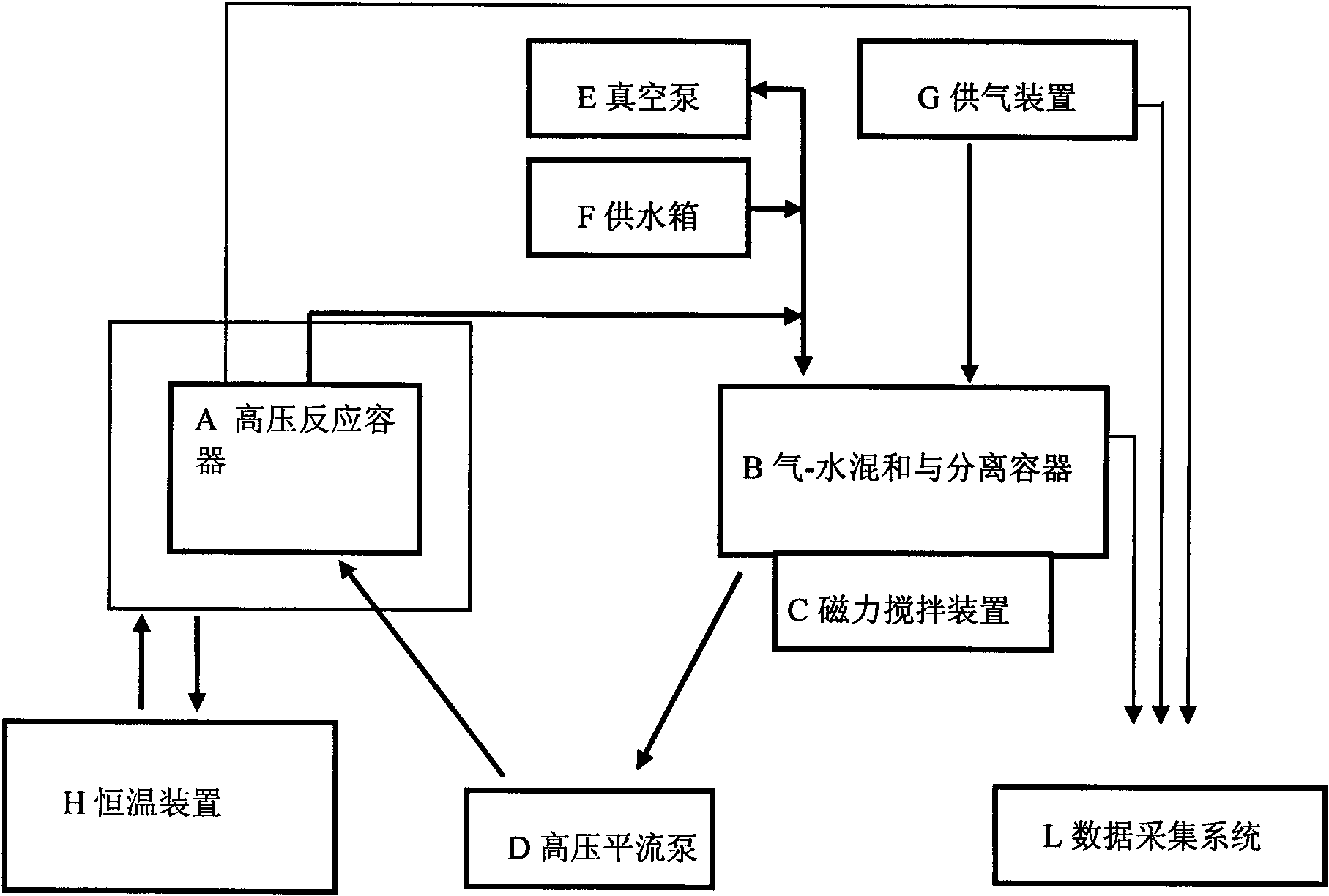

[0063] A device (referred to as the test device) that can effectively simulate the preparation method of the seabed natural gas diffusion and migration to form hydrates, according to figure 2 It can be seen that the device includes a high-pressure reaction vessel A, a gas-water mixing and separation high-pressure vessel B, a magnetic stirring device C, a high-pressure advection pump D, a vacuum pump E, a water supply tank F, a gas supply device G, a constant temperature device H, and a data acquisition system L (including various sensors, 2 temperature sensors and 1 pressure sensor), ordinary valve V (composed of seven valves V-1-V-7), the first gas storage cylinder G-1, and high-pressure pipeline M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com