Gas concentration detection system capable of working under explosion environment of explosive

A gas concentration detection and gas concentration technology, which is applied in the field of explosive performance testing of explosives, can solve the problems of difficulty in obtaining gas concentration parameter values, and achieve the effects of wide measurement range, extreme response time, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

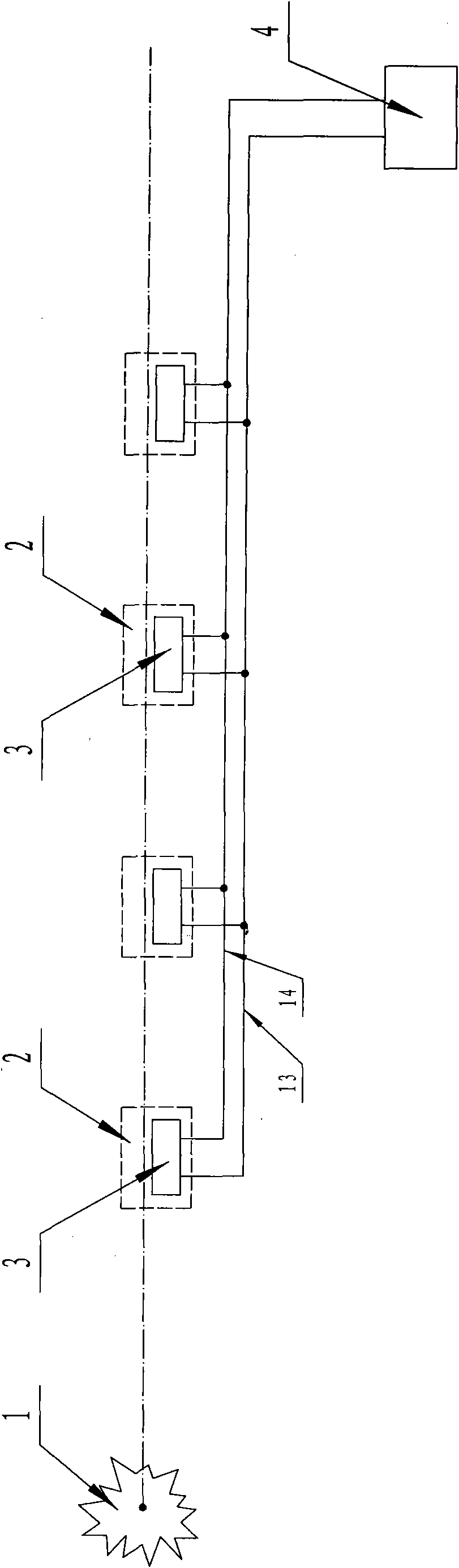

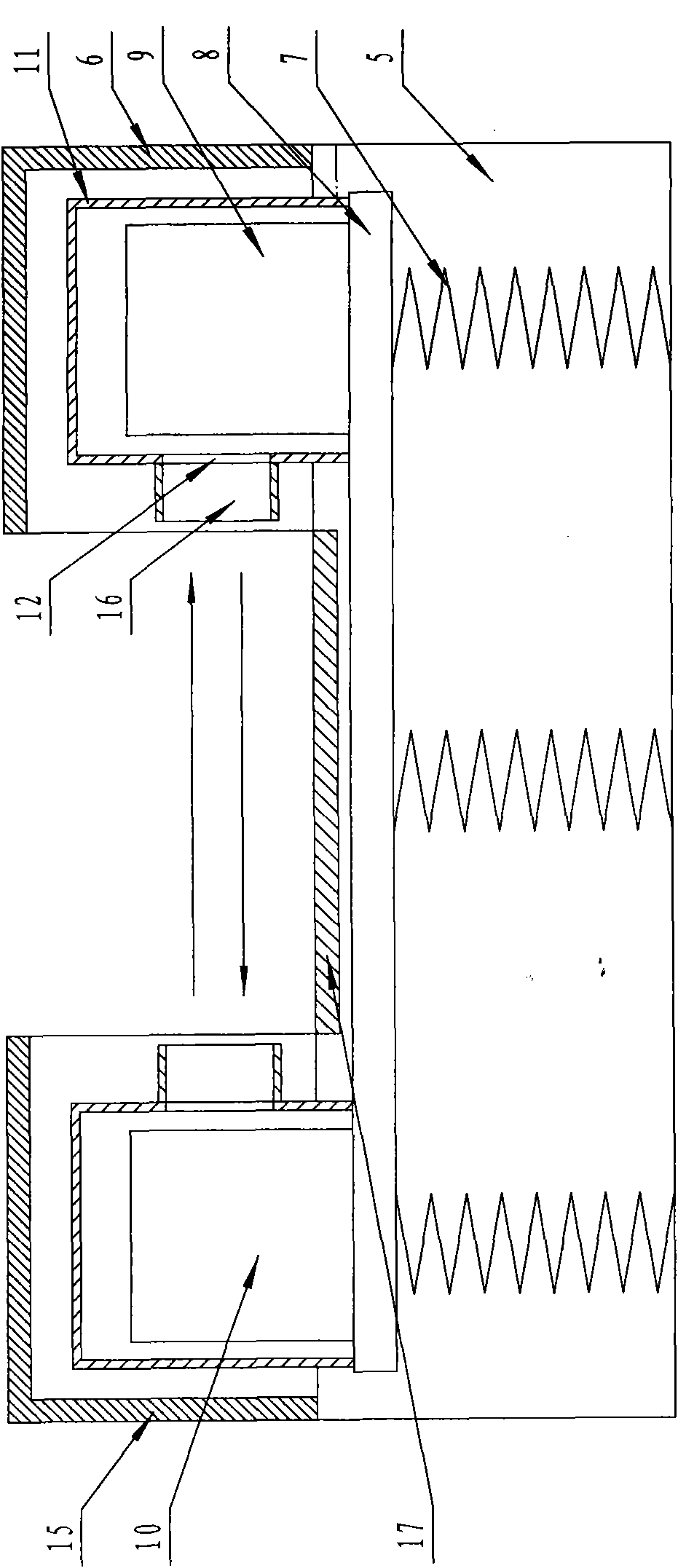

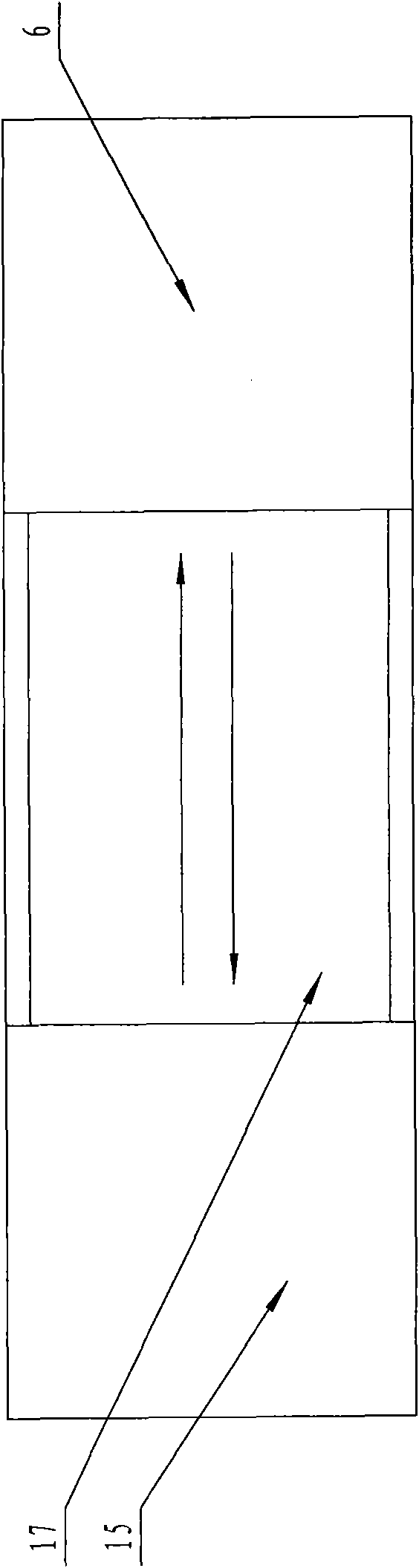

[0017] As attached Figure 1-3 As shown, the gas concentration detection system used in the explosive environment of explosives includes a number of test points 2 arranged in the same ray direction with explosive initiation point 1 as the end point in the area affected by the explosion of explosives. The gas concentration sensing device 3 of 2 and the gas concentration analyzer 4 arranged at the remote end; the ground of each test point 2 is provided with a straight groove 5 perpendicular to the arrangement direction of the test points 2, and the two ends of the straight groove 5 Each cover is provided with cement protective covers 6, 15 protruding from the ground and facing the window side; the gas concentration sensing device 3 includes a bottom frame 8 with high-strength shock-absorbing springs 7 evenly distributed underneath, which are respectively fixed to the bottom The tunable diode laser emitting and receiving device 9 and the laser reflecting device 10 are arranged opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com