Printing using a structure coated with ultraviolet radiation responsive material

A radiation reaction, ultraviolet technology, applied in the production of special varieties of prints, photosensitive materials for optomechanical equipment, printing, etc., can solve the problem that the modifier is not photosensitive, changes the state, and the coating cannot be excited by ultraviolet radiation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

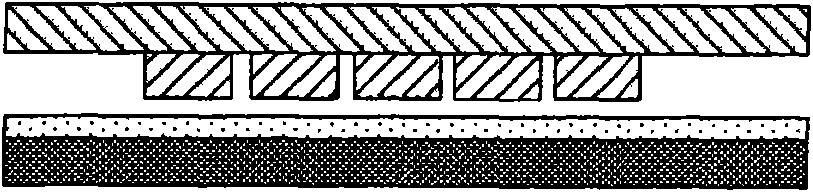

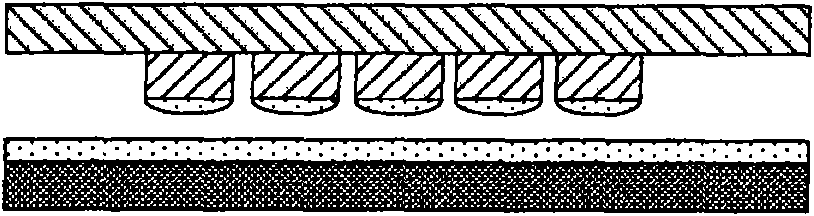

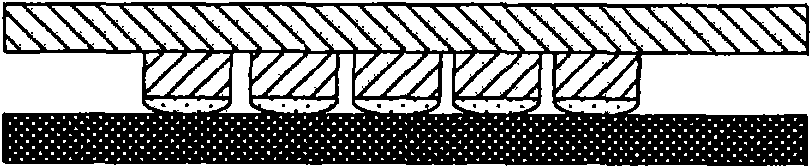

[0017] The present invention relates to the construction of stamp structures with coatings of UV radiation responsive materials and methods of printing with UV radiation reactive materials on stamps and substrate surfaces during printing. The details of the invention are described here with the aid of the accompanying drawings in order to enable a thorough understanding of the constructions described herein, but the invention is not limited thereto. The features, structures, materials, and characteristics of the techniques described above may be combined in any suitable manner in one or more configurations.

[0018] summary

[0019] Ultraviolet radiation or other actinic light exposure is applied to the surface coated with the ultraviolet sensitive material coating. The coating should be able to transform its chemical structure or surface energy in real time to assist the printing process.

[0020] The strategy of the present invention is based on coating the stamp with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com