Compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve the problem of not being able to open too much, and achieve the effect of ensuring the discharge flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

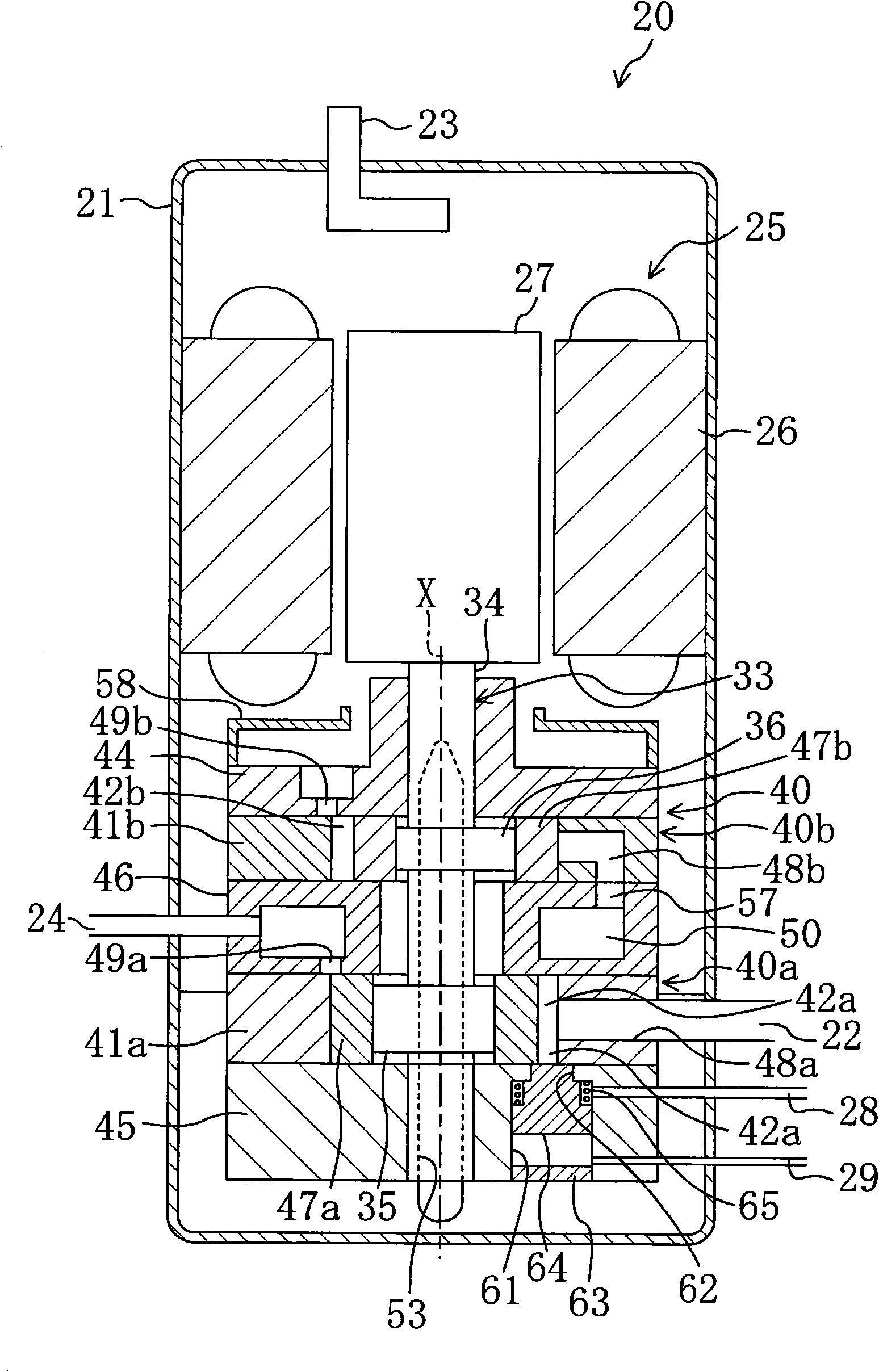

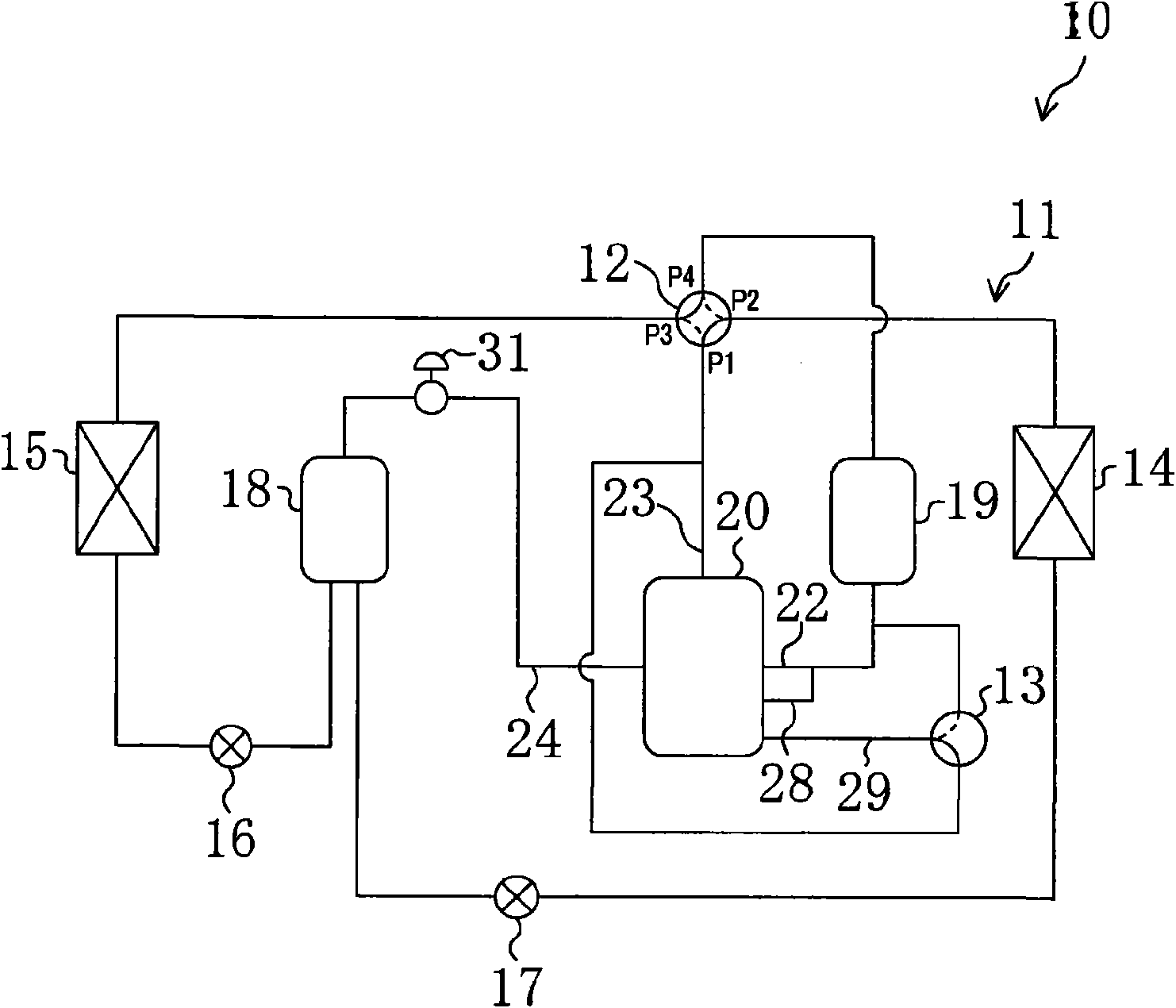

Such as figure 2 As shown, the air conditioner 10 according to the first embodiment of the present invention includes a two-stage compressor 20. This air conditioner 10 includes a refrigerant circuit 11.

[0039] In this refrigerant circuit 11, a two-stage compressor 20, an outdoor heat exchanger 14, an indoor heat exchanger 15, a first expansion valve 16, a second expansion valve 17, a four-way reversing valve 12, and a three-way reversing valve are connected. Valve 13, gas-liquid separator 18, and accumulator (accumulator) 19.

[0040] In detail, the discharge side of the two-stage compressor 20 is connected to the first port of the four-way switching valve 12 through the discharge pipe 23. In addition, the suction side of the two-stage compressor 20 is connected to the bottom of the accumulator 19 through a suction pipe 22. Also, the top of the accumulator 19 is connected to the fourth valve port of the four-way reversing valve 12. In addition, one end of the outdoor heat excha...

no. 2 approach

Next, the second embodiment of the present invention will be explained. The two-stage compressor 220 according to this second embodiment is different from the first embodiment in that the bypass passage is provided in the high-stage compression mechanism 240b, and the enclosed volume of the high-stage compression mechanism 240b is changed. That is, the low-stage compression mechanism 240a constitutes a second compression mechanism, and the high-stage compression mechanism 240b constitutes a compression mechanism. In addition, the same components as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof will be omitted.

[0110] Specifically, on the front top 244, such as Figure 8 As shown, as with the rear top 45 of the first embodiment, the large-diameter valve body receiving hole 261 penetrates from its upper surface to the lower surface, and the valve body receiving hole 261 faces the front top from the bottom of the valve body receiv...

no. 3 approach

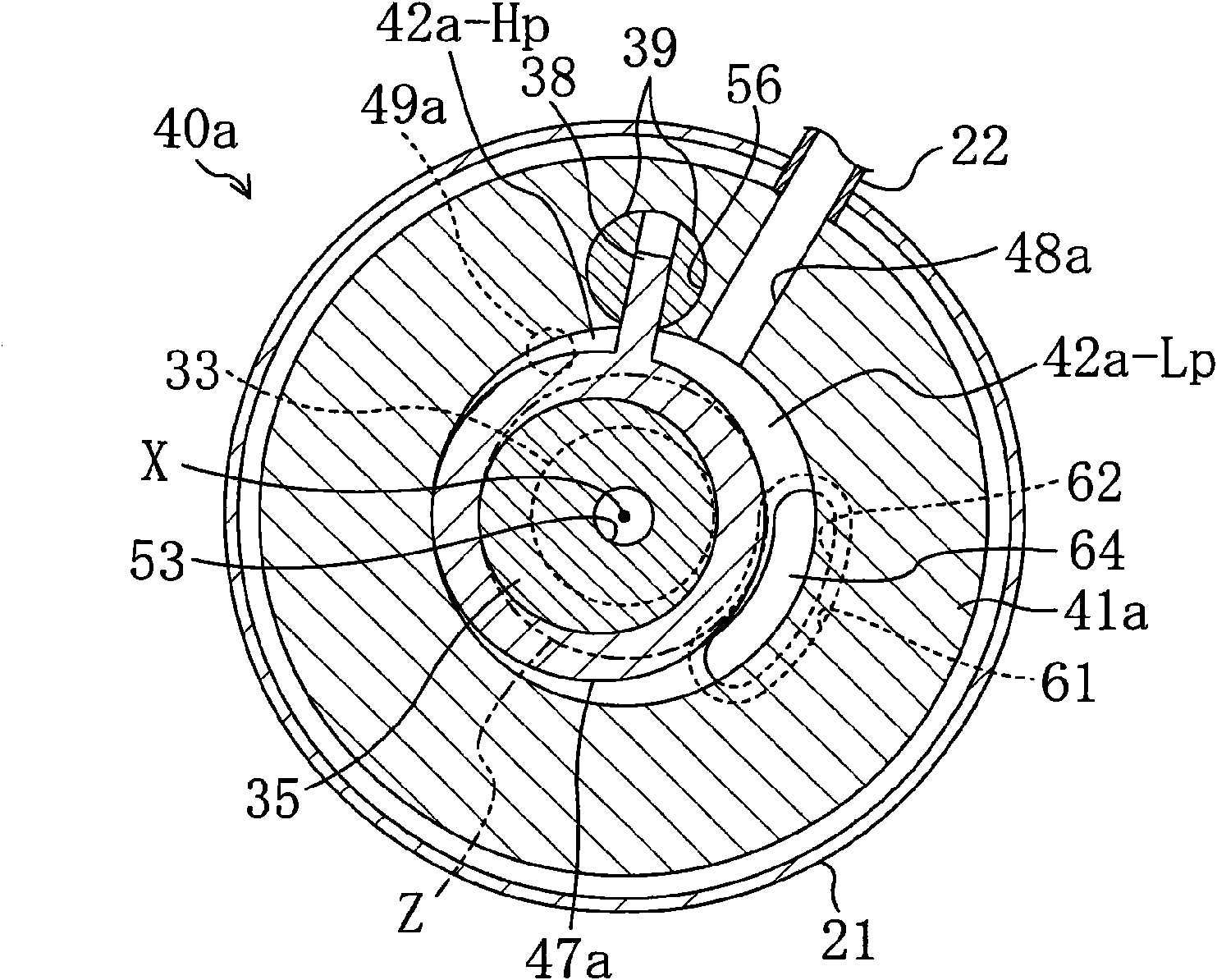

Next, a third embodiment of the present invention will be explained. The two-stage compressor 320 according to the third embodiment differs from the first embodiment in that a valve body accommodating hole 361 and a bypass hole 362 are formed on the side wall of the lower-stage cylinder 341a of the lower-stage compression mechanism 340a . In addition, the same configuration as the first embodiment is denoted by the same reference numeral, and the description is omitted.

[0119] The two-stage compressor 320 involved in the third embodiment is such as Picture 9 As shown, the valve body receiving hole 361 and the bypass hole 362 are formed on the side wall of the lower-stage side cylinder 341a, not on the rear top. A valve body housing hole 361 and a bypass hole 362 are formed in order from the radially outer side to the inner side on the side wall of the lower-stage side cylinder 341a. While the bypass hole 362 opens on the inner peripheral surface of the lower-stage side cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com