Surface carving technology of metal jewelry

A metal and technical technology, applied in the field of engraving on the surface of metal jewelry, can solve the problems of poor effect, high production cost, delicate pattern effect, unclear pattern, etc., and achieve clear and obvious patterns, smooth lines, and improve ornamental and artistic quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to illustrate the idea and purpose of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

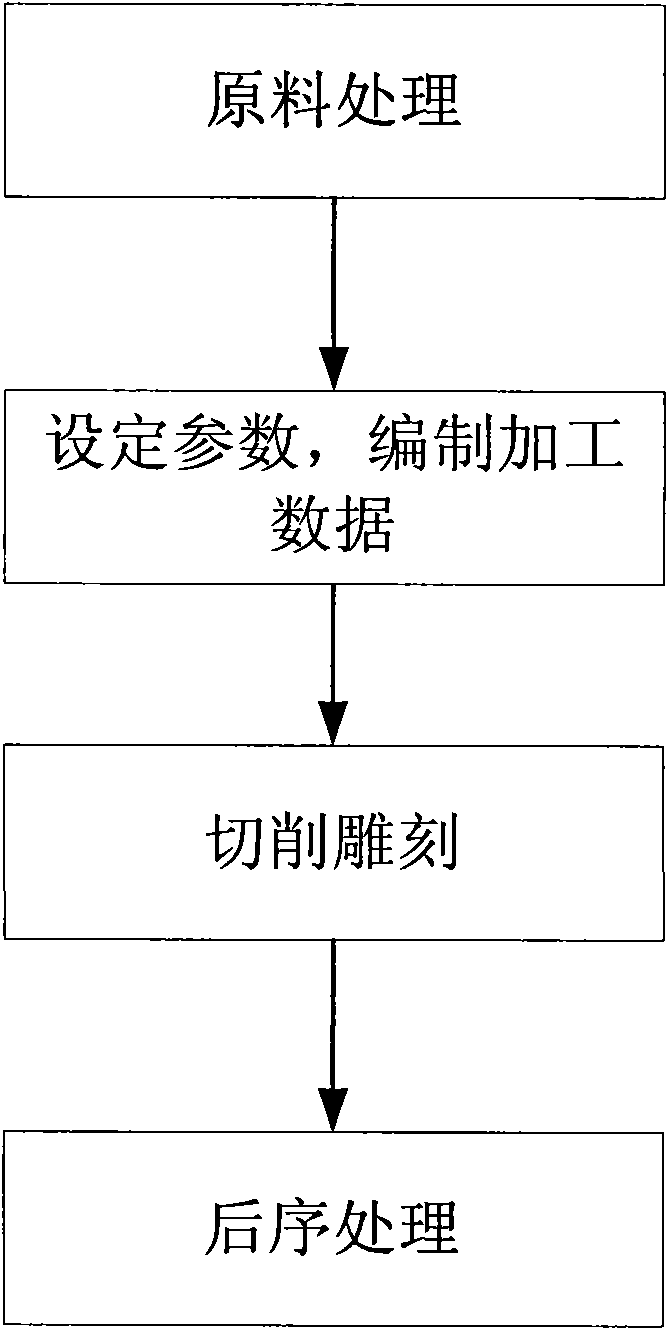

[0014] See figure 1 As shown, a metal jewelry surface engraving process mainly includes the following steps:

[0015] (1) Raw material processing: the metal is melted and drawn into a plate shape, and the plate metal is stamped out of the corresponding shape, and then shaped by cutting.

[0016] Specifically: first select a certain amount of metal (gold or silver), and add a certain proportion of other metals (such as platinum) to melt in the smelting equipment, and form an alloy between the two, and then the resulting alloy melt Casting into a mold of a specific shape, pulling out the plate-shaped metal material; then cooling the plate-shaped metal material, and punching out the corresponding shape through stamping, hydraulic equipment and pre-made molds (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com