Curving-type monorail crane and traveling method thereof

A monorail crane and variegated technology, which is applied in the direction of traveling mechanism, load suspension components, load block, etc., can solve the problem of not being able to carry power supply equipment and spray pumps along the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

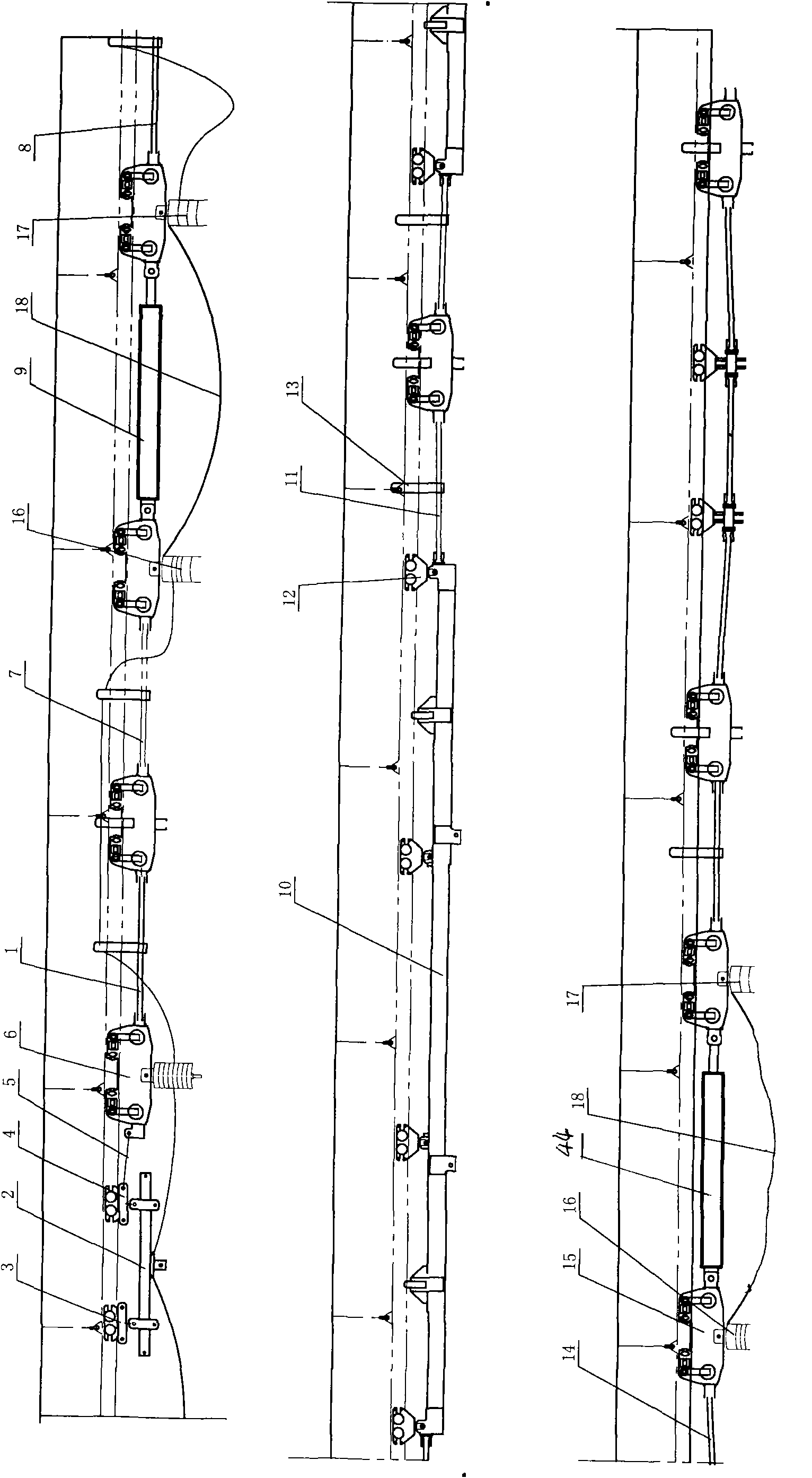

[0033] Example: figure 1 , Figure 16 As shown, there are 44 carrying devices and 16 braking devices in this embodiment connected by connectors or hydraulic cylinders (traveling hydraulic cylinders) or pull rods, and two of them are connected by traveling hydraulic cylinders. Two parts of the middle section are connected by connectors, and the rest are connected by tie rods of different lengths.

[0034] The present embodiment is divided into three sections with two walking hydraulic cylinders as the dividing point, that is, the middle section between the two walking hydraulic cylinders, the front section before the walking hydraulic cylinder 44, and the rear section after the walking hydraulic cylinder 9. The rear section is composed of 16 carrying trolleys and 4 braking devices connected by pull rods, and 8 cable carrying trolleys are composed of 16 carrying trolleys for carrying cables. Figure 16 As shown, the cable carrying vehicle 2 is formed by connecting two carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com