Target type flowmeter of non-contact type displacement sensor

A technology of displacement sensor and target flow, which is applied in the direction of volume/mass flow generated by mechanical effects, and the dynamic effect of fluid flow through detection, etc., and can solve problems such as drift, seal damage, and measurement data changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

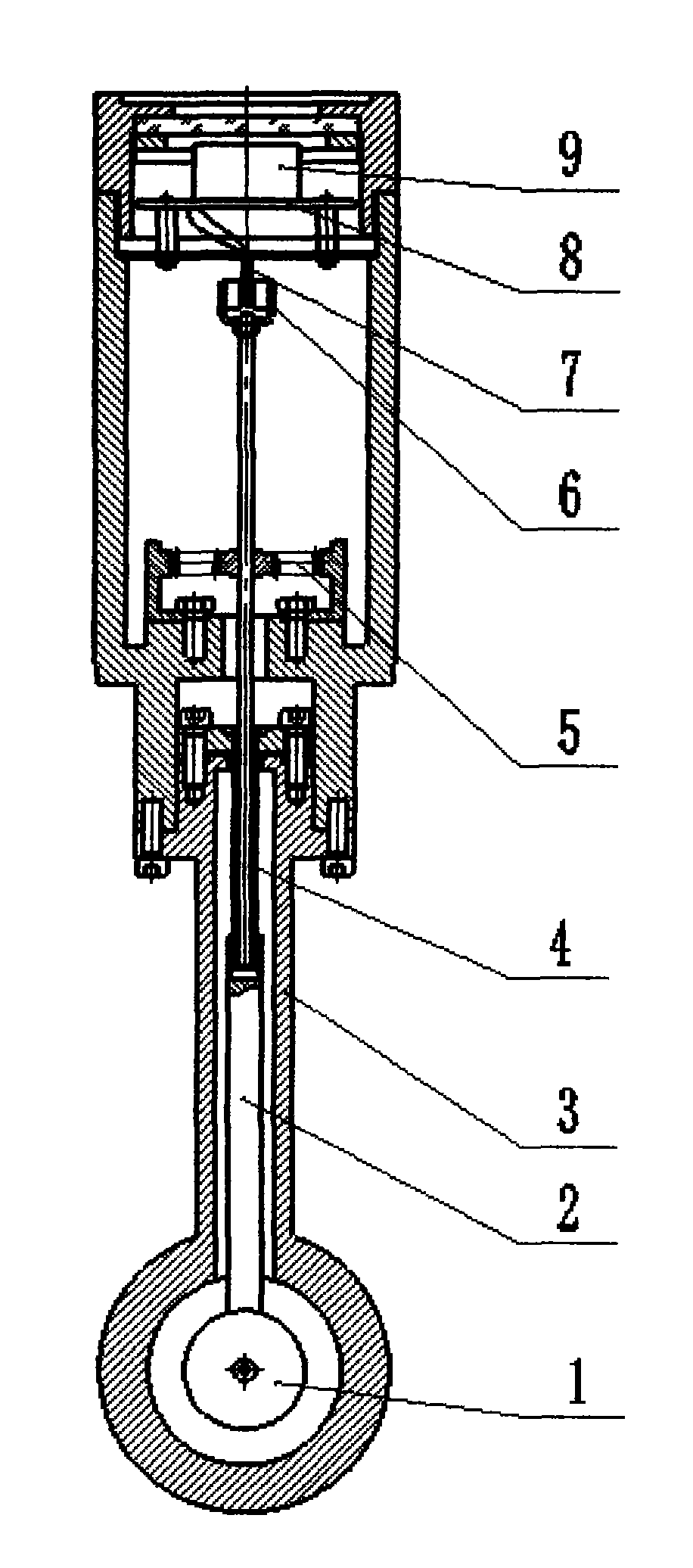

[0009] The structure and measurement method of the present invention are illustrated in conjunction with the accompanying drawings.

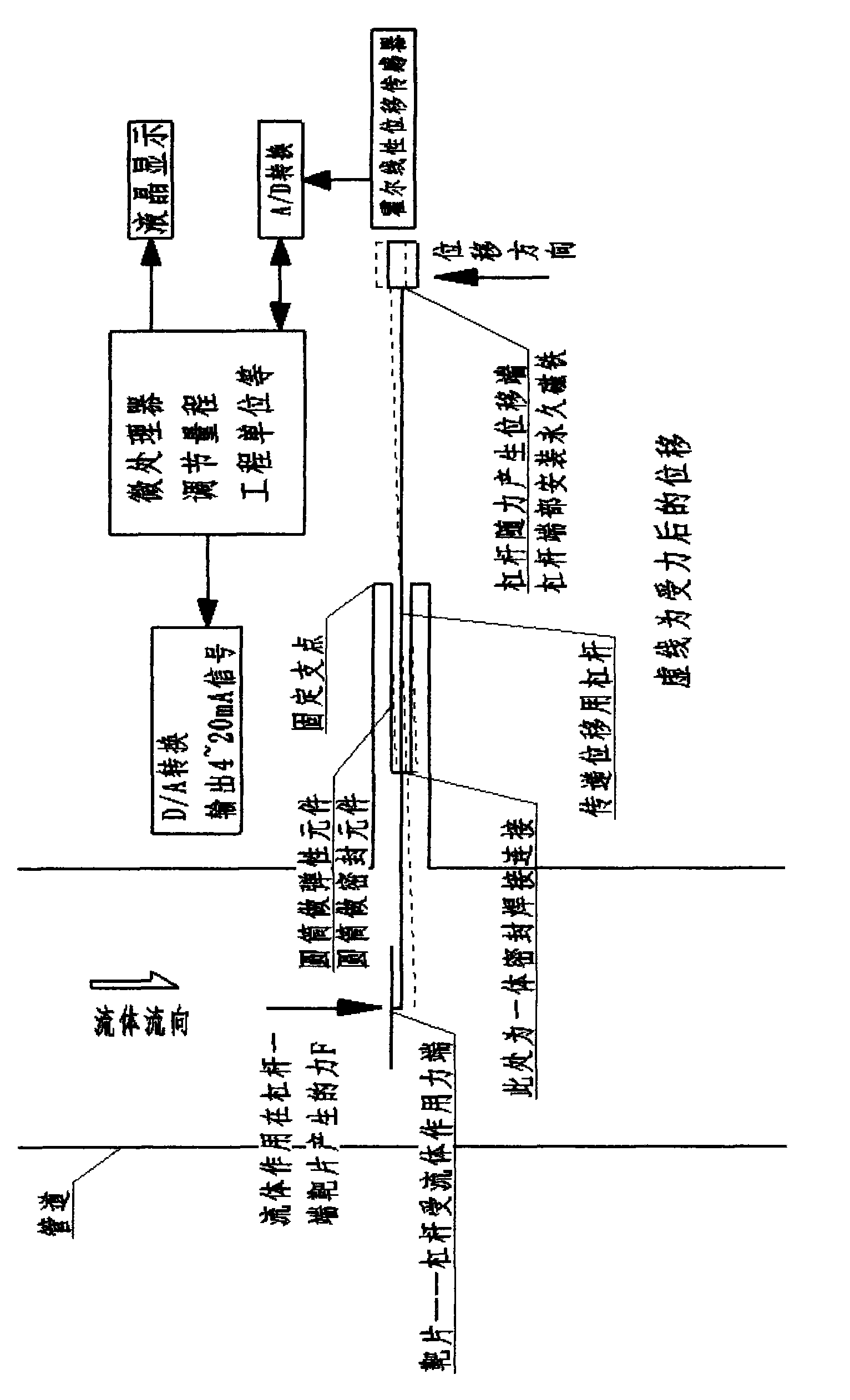

[0010] A non-contact displacement sensor target type flowmeter, in which an elastic element 4 is installed in a casing 3, the elastic element is a thin-walled cylinder or a thick-walled cylinder. The elastic element is both an elastic element and a sealing body, and the thick-walled cylinder increases the reliability of the seal and has a large anti-overload capacity. The target rod 2 is installed in the elastic element 4, the target piece 1 is installed at the lower end of the target rod 2, the mechanical damping device 5 is installed on the upper part of the target rod 2, and the top of the target rod 2 is provided with a The detection displacement magnet 6 is equipped with a Hall linear displacement sensor 7 at the corresponding position of the detection displacement magnet 6. The sensor is placed far away from the medium and can be made into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com