Processing box

A process cartridge and sliding element technology, which is applied in the field of process cartridges for electrophotographic imaging devices, can solve the problems of manufacturing accuracy requirements and high cost of the process cartridges, and achieve the requirements of solving manufacturing accuracy requirements and high costs, reducing friction and reducing manufacturing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

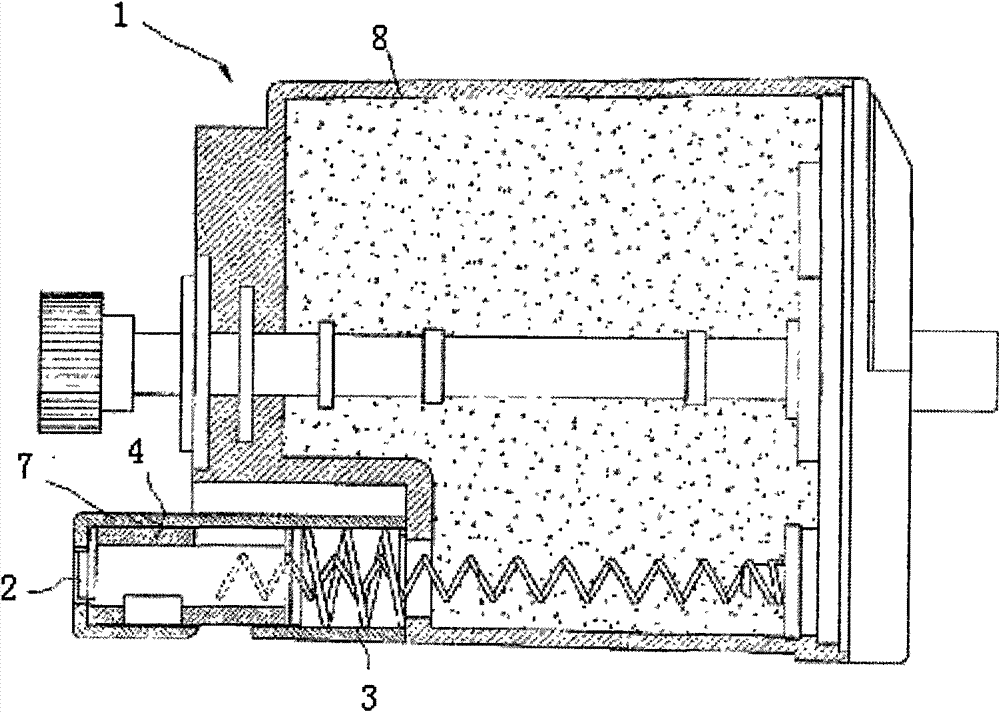

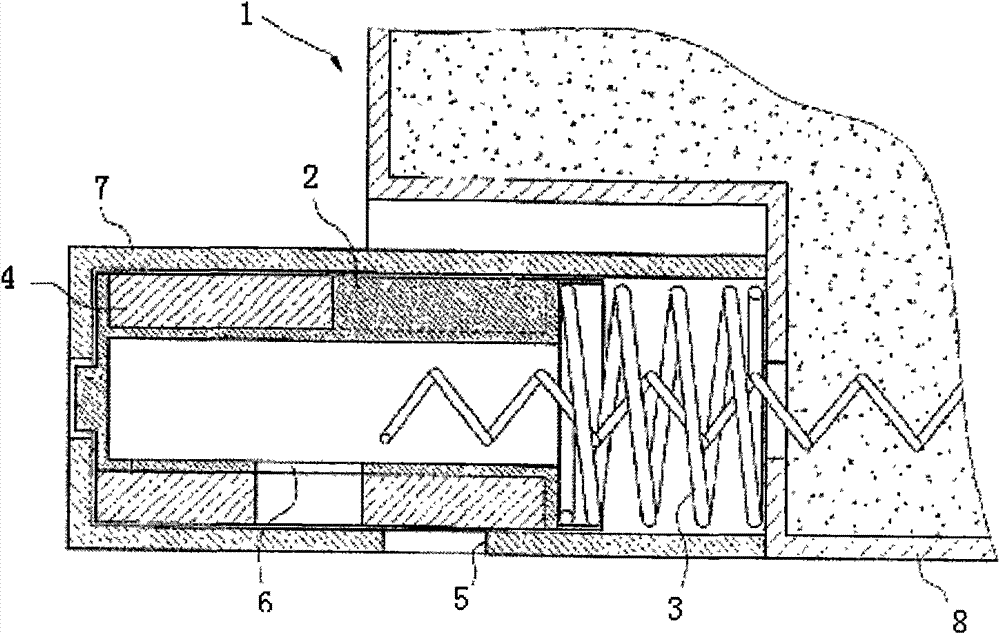

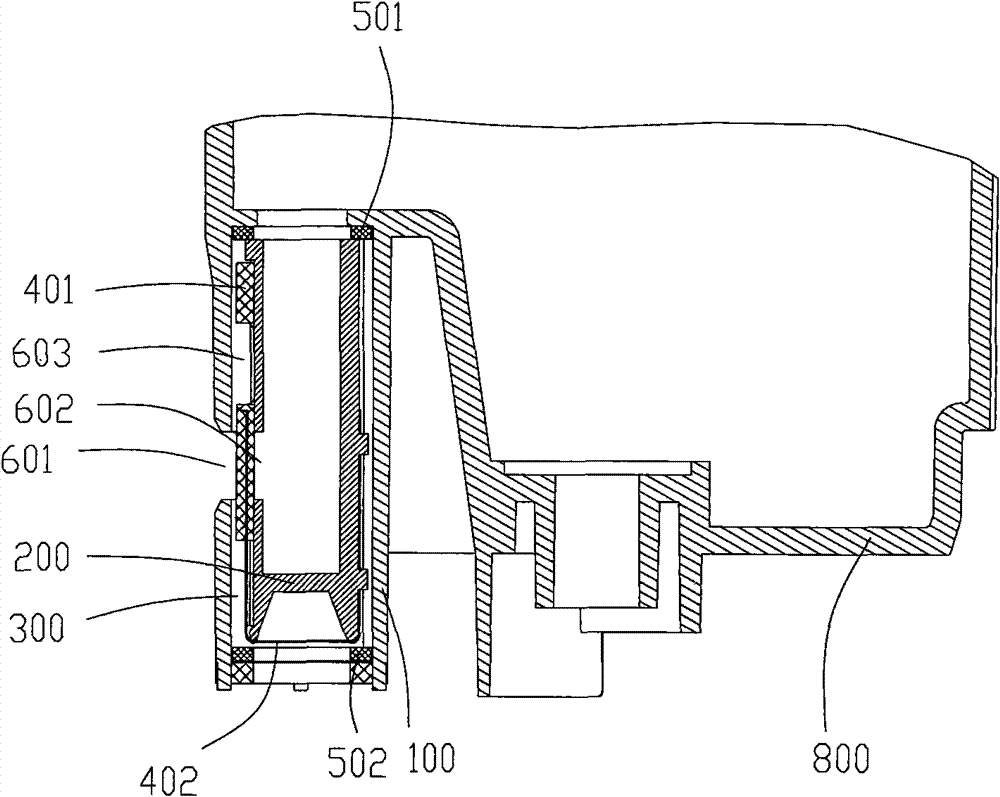

[0023] Such as image 3 , Figure 4 As shown, the processing box includes a main body 800 and a powder feeding part 100, the powder feeding part 100 is fixed on the main body 800; the powder feeding part 100 has a powder outlet 601; the internal element 200 is arranged inside the powder feeding part 100 and is fixed Inside the powder feeding part 100, the internal element 200 and the powder feeding part 100 form a slideway 300; there is an internal powder feeding port 602 on the internal part 200, and the internal powder feeding port 602 is facing the powder outlet 601, and the internal component 200 Sealing elements 501 and 502 are respectively provided at both ends of the toner to prevent leakage of carbon powder; the sliding element can slide on the slideway, and the sliding element has an elastic opening 603;

[0024] Such as Figure 5 , Figure 6 As shown, the sliding element includes an elastic part 401 and a stretching part 402, the elastic part 401 is made of elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com