Integral type stopper capable of controlling inflow gas

An integral, stopper technology, applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc., can solve the problems of increasing leakage points, harsh raw materials and precision, and non-concentration, so as to reduce parts and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

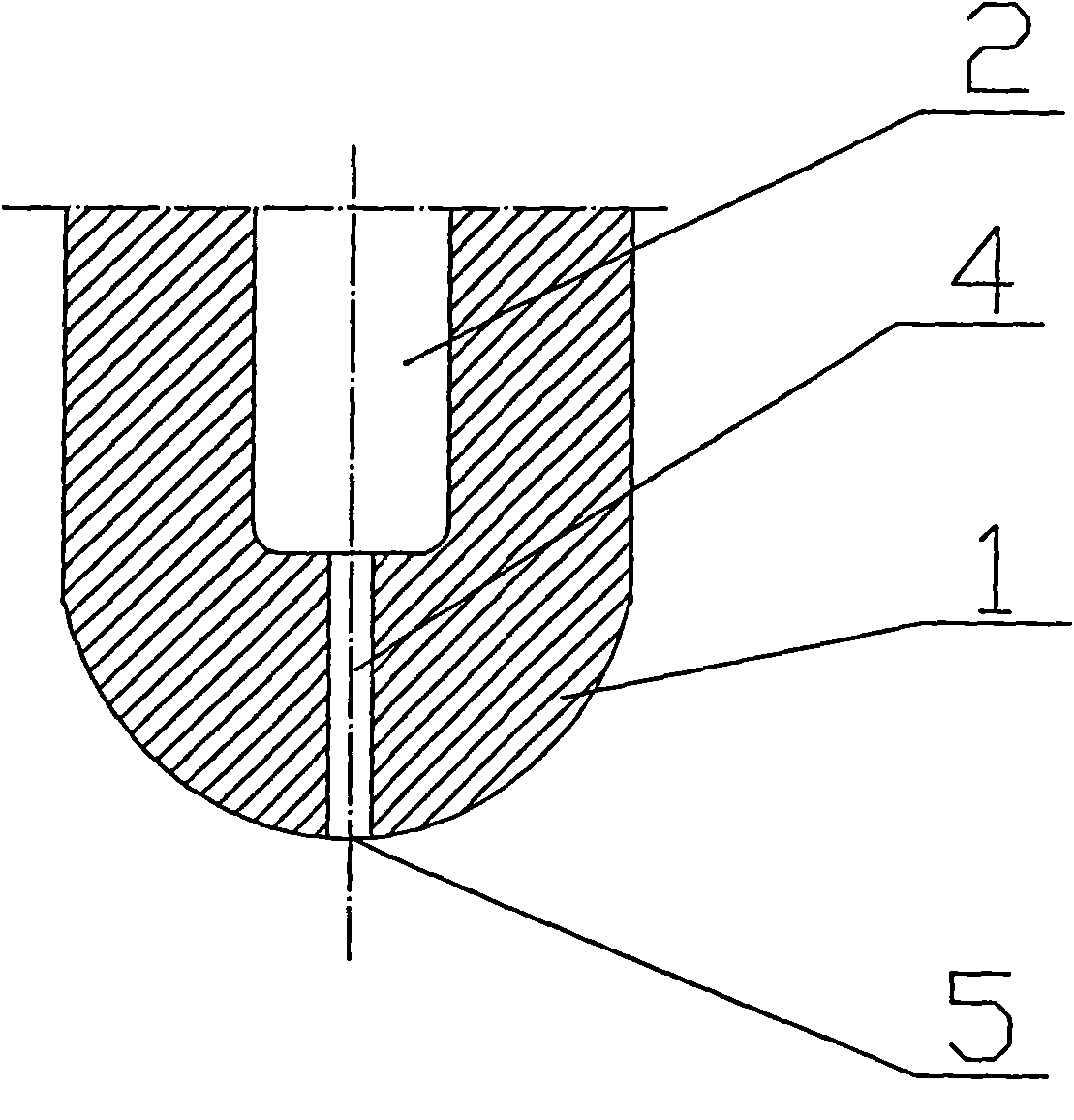

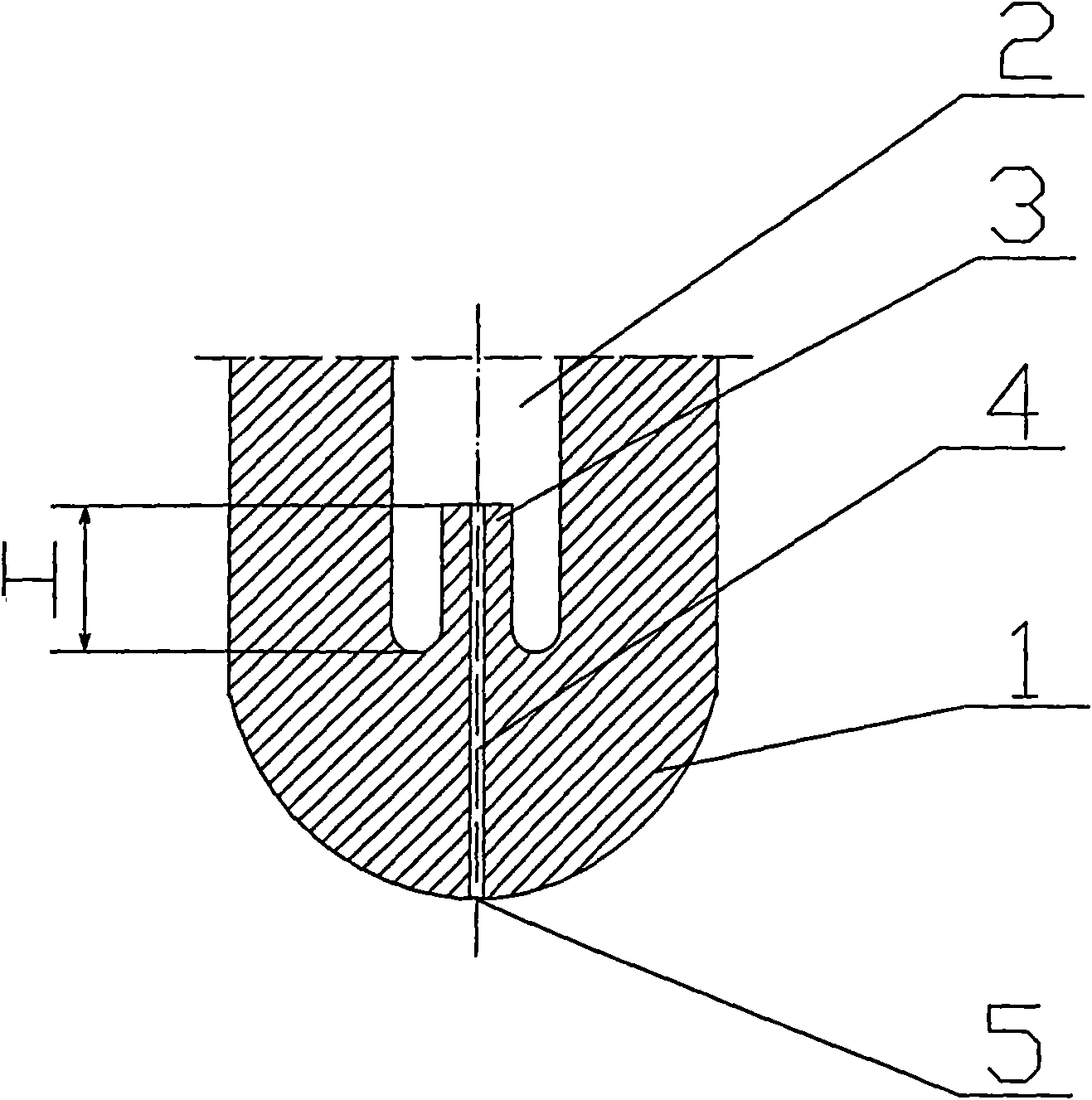

[0023] An integral plug rod that can control the inflow of gas, comprising a plug rod body 1, an internal chamber 2 located in the plug rod body 1, a gas discharge port 5 located at the end of the plug rod body 1, the internal chamber 2 and the gas discharge port 5 is communicated and connected through the gas channel 4, the inner chamber 2 is provided with a gas inlet column 3 extending upward and higher than the bottom end of the inner chamber 2 at one end of the gas channel 4, and the gas channel 4 extends upward to the top opening of the gas inlet column 3, and communicate with the inner chamber 2; an annular cavity is formed between the outer wall of the gas inlet column 3 and the inner wall of the inner chamber 2; the gas inlet column 3 and the stopper body 1 are integrated.

[0024] The gas channel 4 is a tubular channel of equal diameter or a tapered channel of unequal diameter or a stepped channel of unequal diameter from the top opening of the gas inlet column 3 to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com