Self-calibration linear displacement type filling machine for liquid

A self-calibrating, volumetric technology, used in liquid bottling, liquid distribution, conveying or transfer devices, liquid handling, etc. High, strong adaptability, convenient barreling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

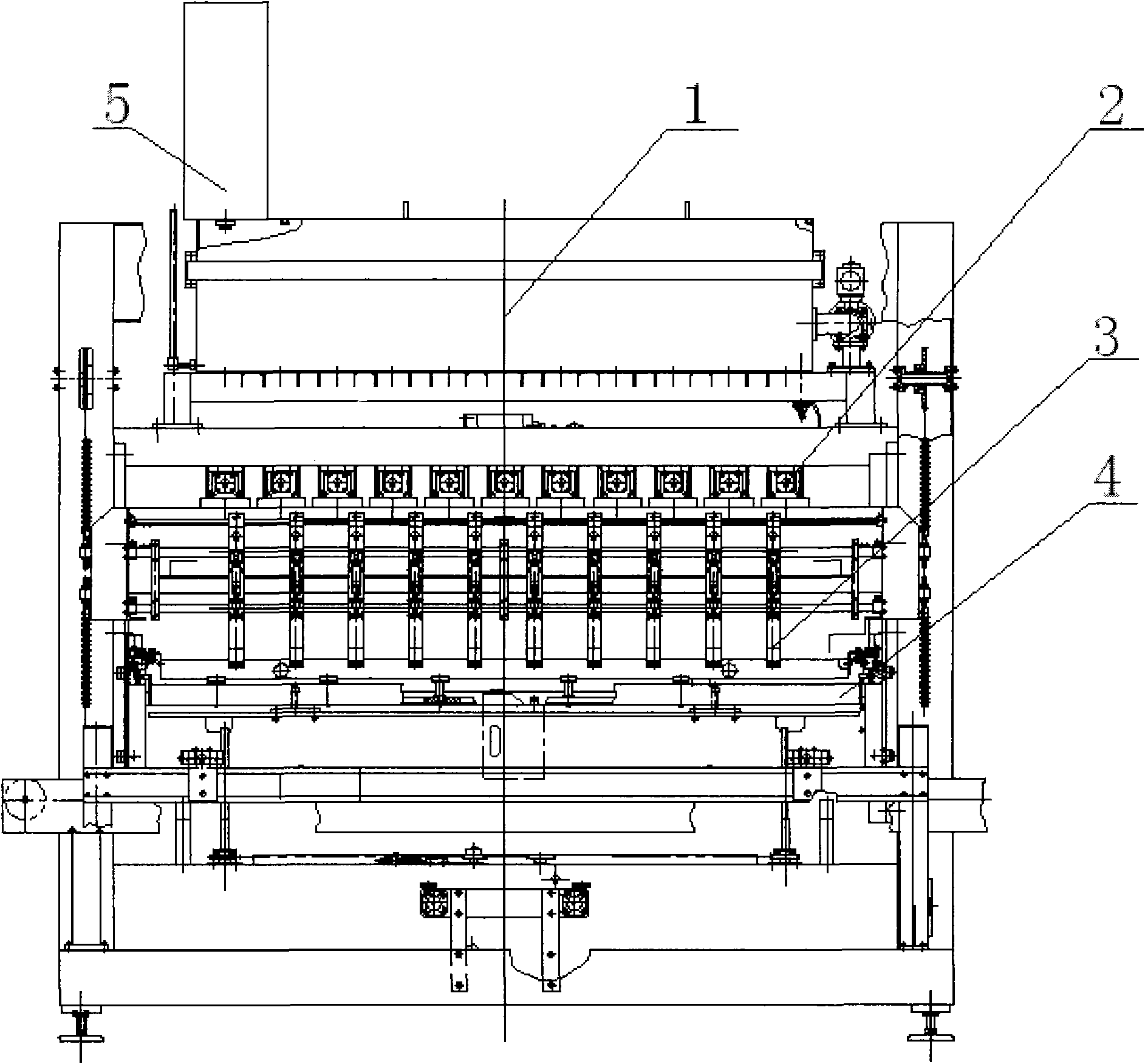

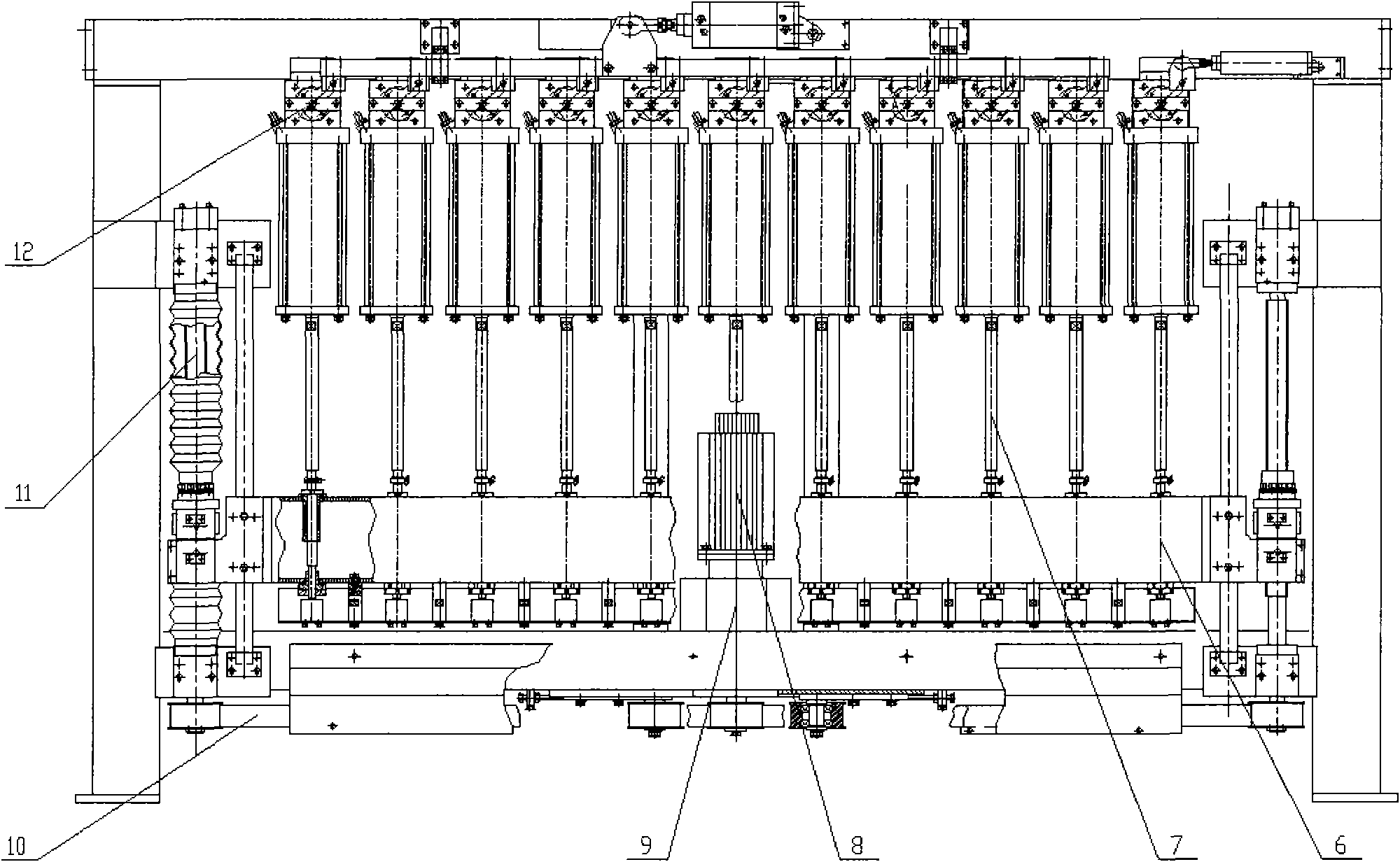

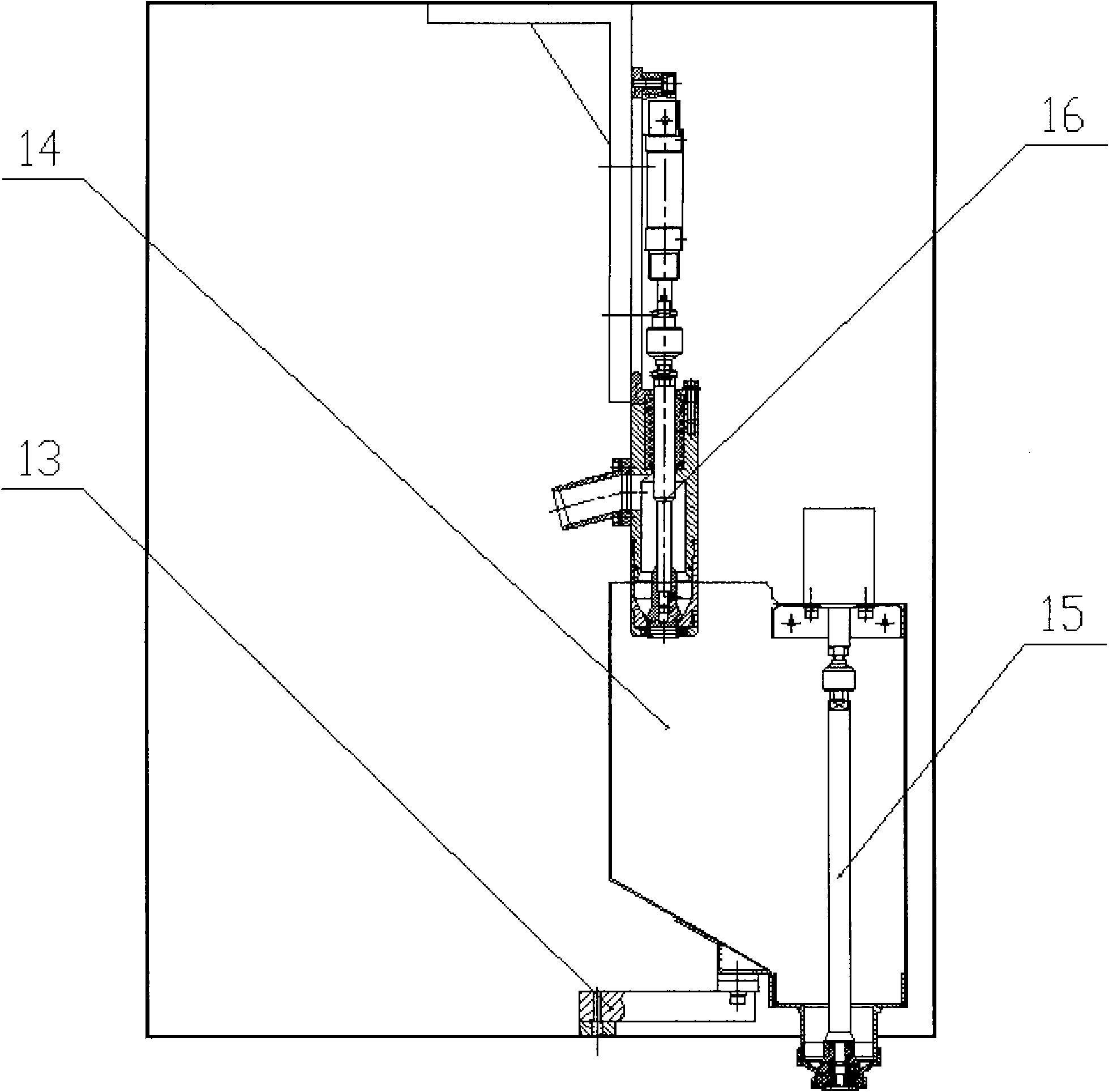

[0012] The research and development of the self-calibrating linear volumetric filling machine makes up for the low precision of the volumetric filling machine and the low speed of the weighing filling machine. It can realize high-precision and high-speed filling, and the filling speed can reach 3500 barrels / Hours, the accuracy is within 7 grams. With the same number of filling heads, the filling speed is twice that of the linear weighing filling machine, and at the same filling speed, the filling accuracy is three times that of the linear volumetric filling machine. At the same time, the self-calibrating linear volumetric filling machine has the characteristics of high degree of automation and convenient operation. It can automatically track the filling volume online through the weighing feedback system, and can automatically adjust the filling volume according to the filling deviation, so that the filling accuracy can be controlled within 7 grams. It can measure the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com