Steel-plastic composite pipe for low-pressure water delivery

A steel-plastic composite pipe and water delivery technology, applied in the field of water delivery pipes, can solve the problems of water leakage or fracture, insufficient welding strength, inconvenient use, etc., and achieve the effects of increasing the service life, increasing the overlapping area and reducing the use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

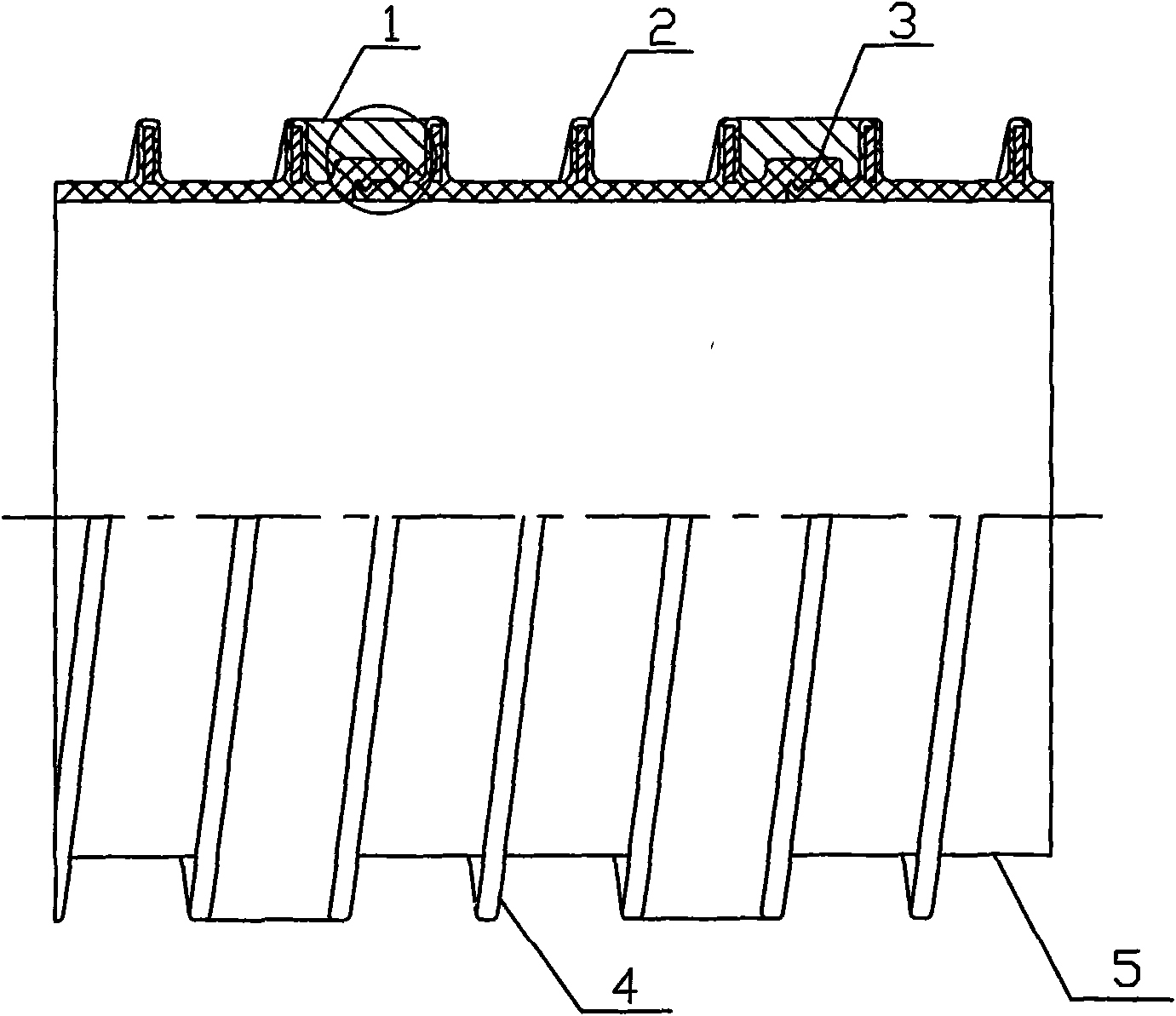

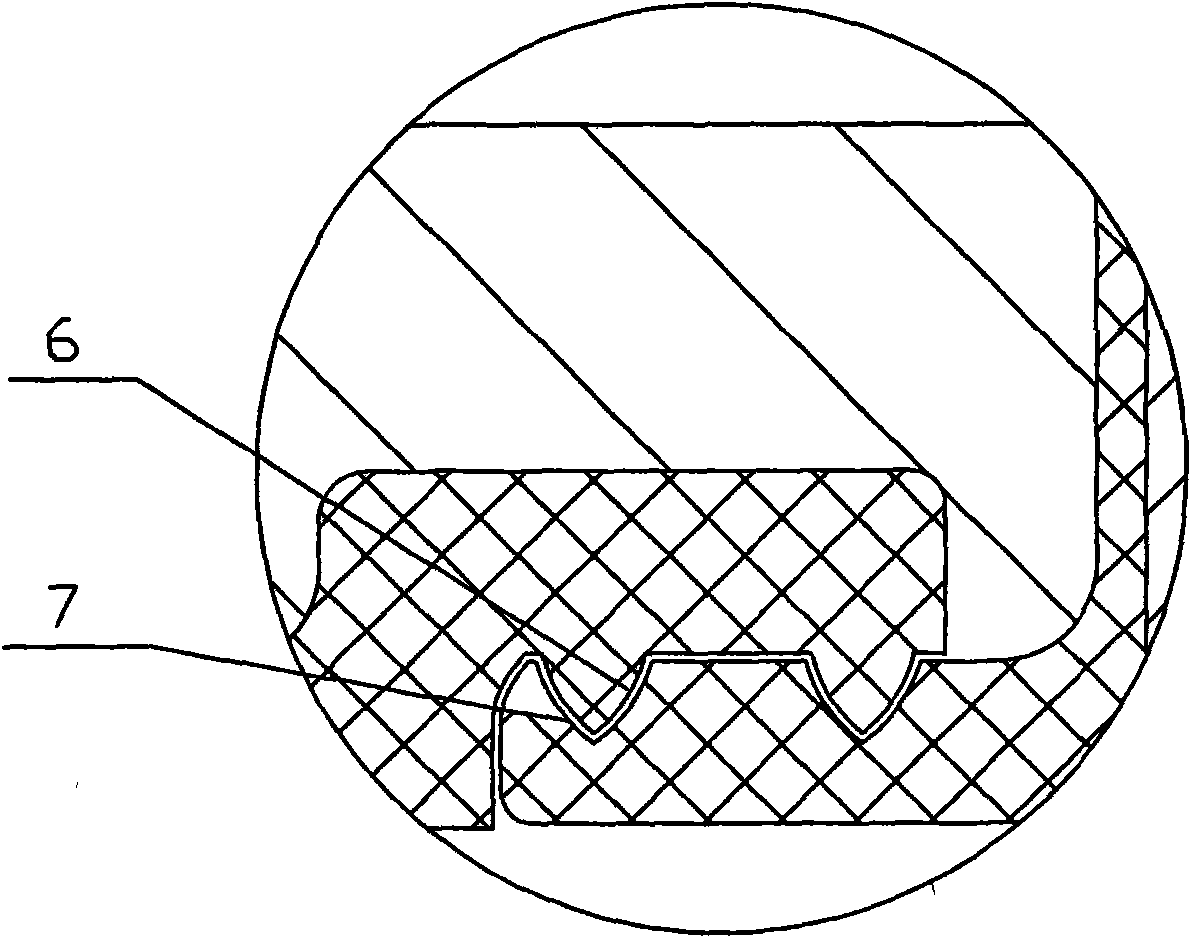

[0014] Refer to the attached figure 1 , attached figure 2 The steel-plastic composite pipe for low-pressure water delivery of the present invention will be described in detail below.

[0015] The steel-plastic composite pipe for low-pressure water delivery of the present invention has a structure comprising a plastic pipe body 5 and a reinforcing rib 4 integrated with the pipe body. The reinforcing rib 4 is compounded with a metal reinforcing belt 2. The plastic pipe body 5 Matching strip-shaped protrusions 6 and strip-shaped grooves 7 are respectively provided on the overlapping surface 3 , and the protrusions 6 are respectively located in the corresponding grooves when the plates are welded in a spiral seam. The number of said protrusions and grooves is 2 respectively, of course, it can also be one or more. A reinforcing surface 1 is annularly wound between two reinforcing ribs 4 with overlapping surfaces 3 to increase the welding strength of the overlapping surfaces 1 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap