Planar motor adopting groove-type coil

A planar motor and coil technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of decreasing density and affecting the thrust of the motor, improving acceleration and load capacity, avoiding mutual cancellation, high air gap body Effect of Current Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure, mechanism and working process of the present invention will be further described below in conjunction with the accompanying drawings.

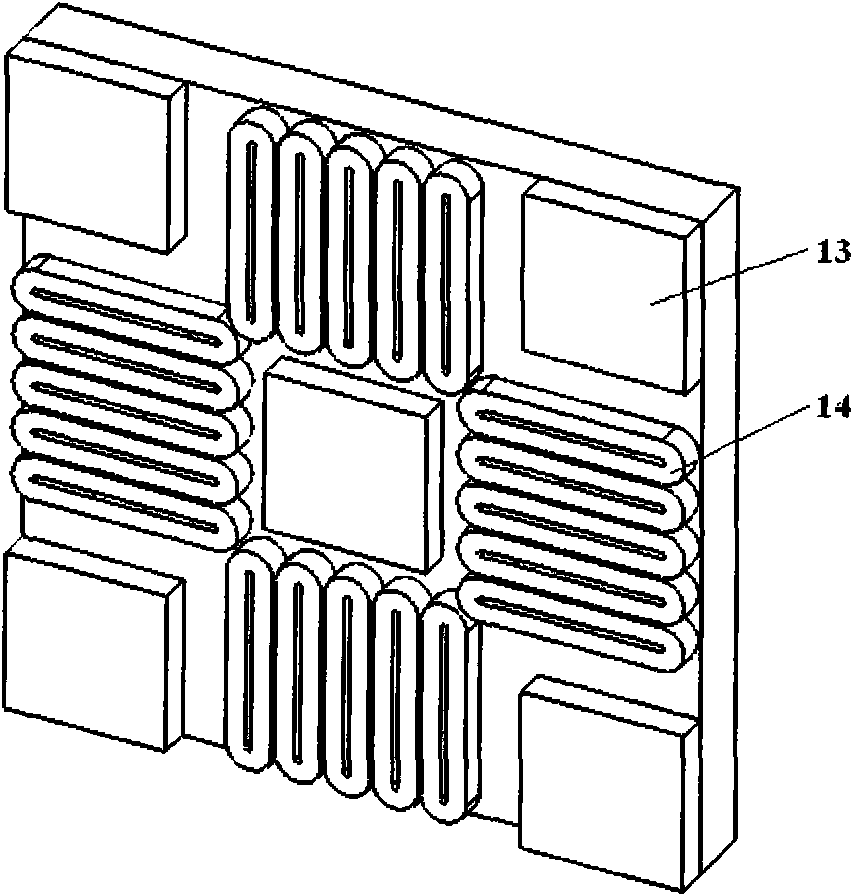

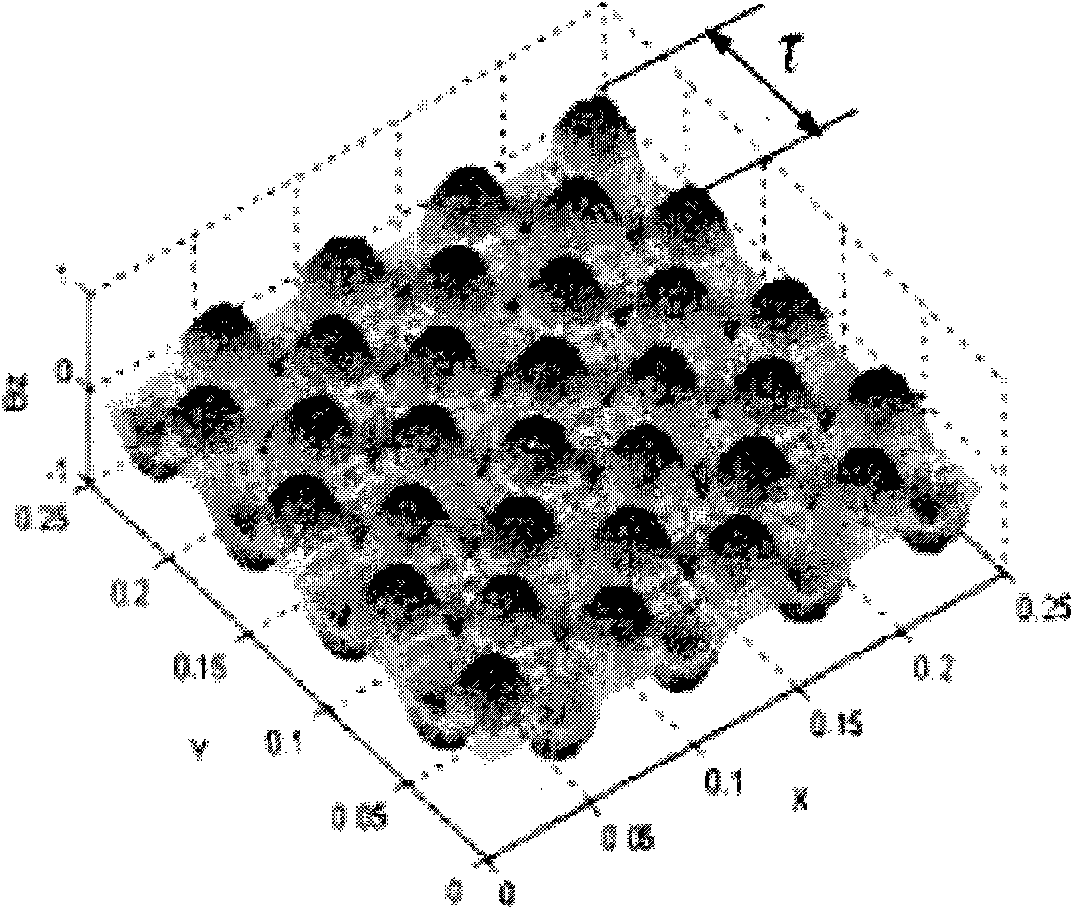

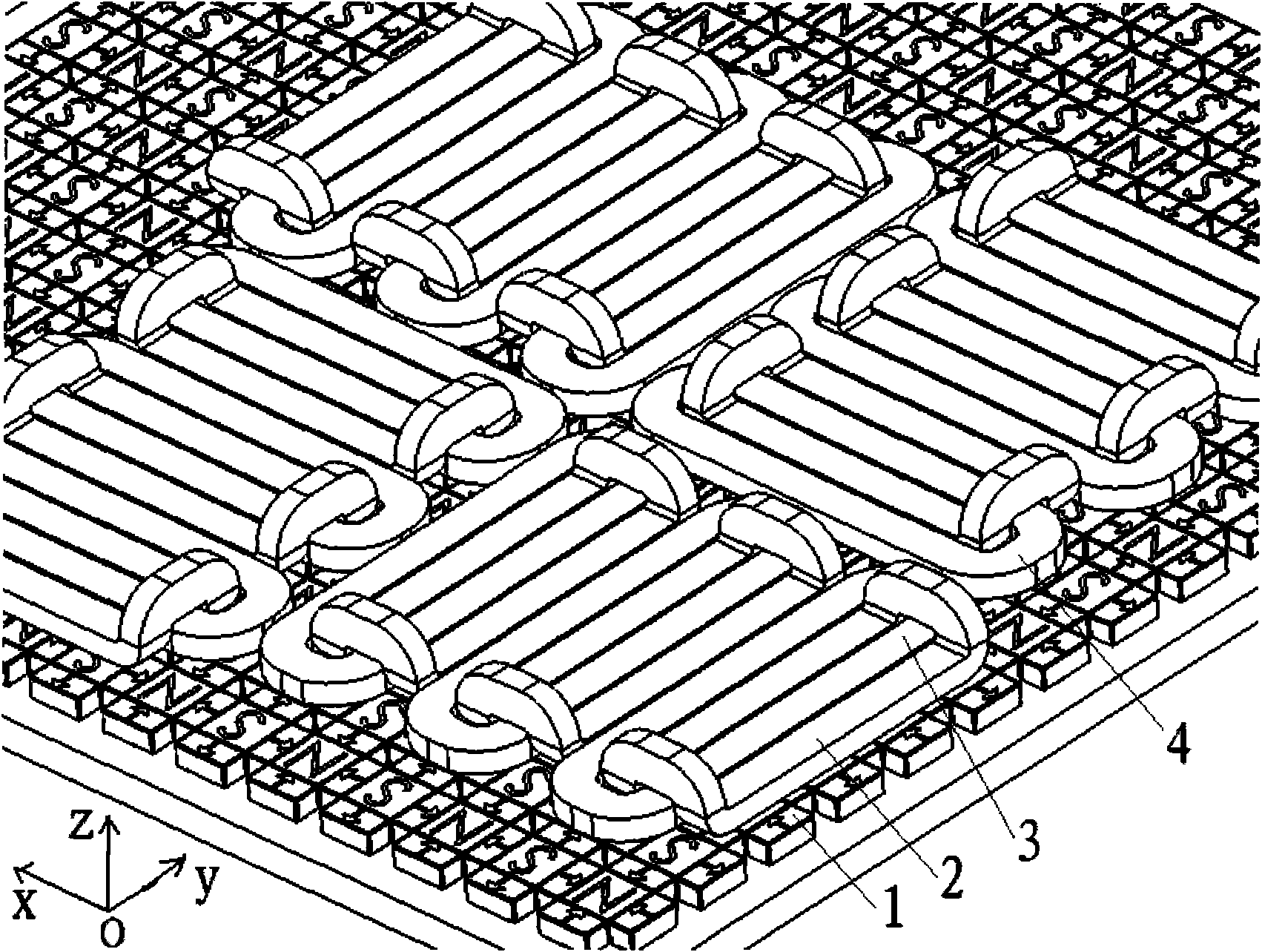

[0020] image 3 It is a three-dimensional view of a planar motor using slot coils according to the present invention, including a mover 4 and a stator 1. The planar motor includes a moving coil structure using a coil array as a mover or a moving iron structure using a coil array as a stator structure, the coil array is composed of a plurality of one-dimensional coil arrays, and each one-dimensional coil array is staggered by an iron-less rectangular coil 3 and an iron-free slot coil 2 whose two short sides of the rectangle are upturned into a slot shape Arranged, one long side of an adjacent slot-shaped coil 2 is embedded between the two long sides of each rectangular coil 3 (such as Figure 5 As shown), it is also possible to embed one long side of two adjacent slot coils between the two long sides of each rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com