Method for controlling mold cavity resin pressure of injection molding machine

A cavity pressure and pressure control technology, applied in the field of injection molding, can solve problems such as poor precision and stability, and inability to control product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

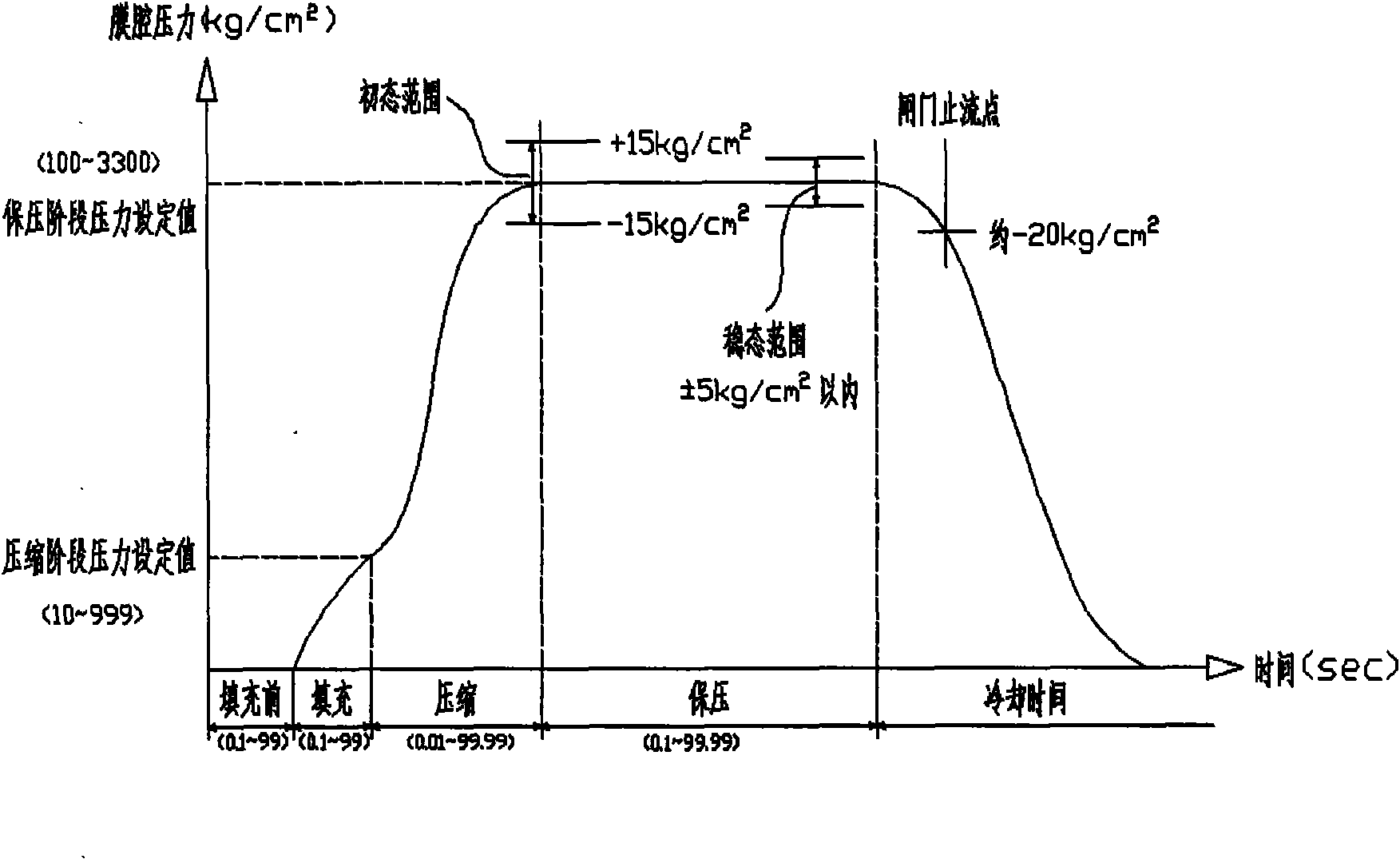

[0027] The present invention comprises the following steps:

[0028] Step 1: Set the detection position of the pressure sensor; firstly, investigate the pressure distribution of each part of the product, and then use the membrane cavity pressure sensor for the purpose of monitoring the molding conditions and controlling the quality of the product. The detection position of the pressure sensor is generally divided into two situations: 1. When the product is perpendicular to the sprue, the detection position is set near the main flow channel. 2. When the product is located on both sides of the sprue and the joint part, set the detection position near a part of the main flow channel. In addition, the stagnant part and bifurcation point of the resin need to be avoided and the selected path must be the path that the end part of the resin must pass through.

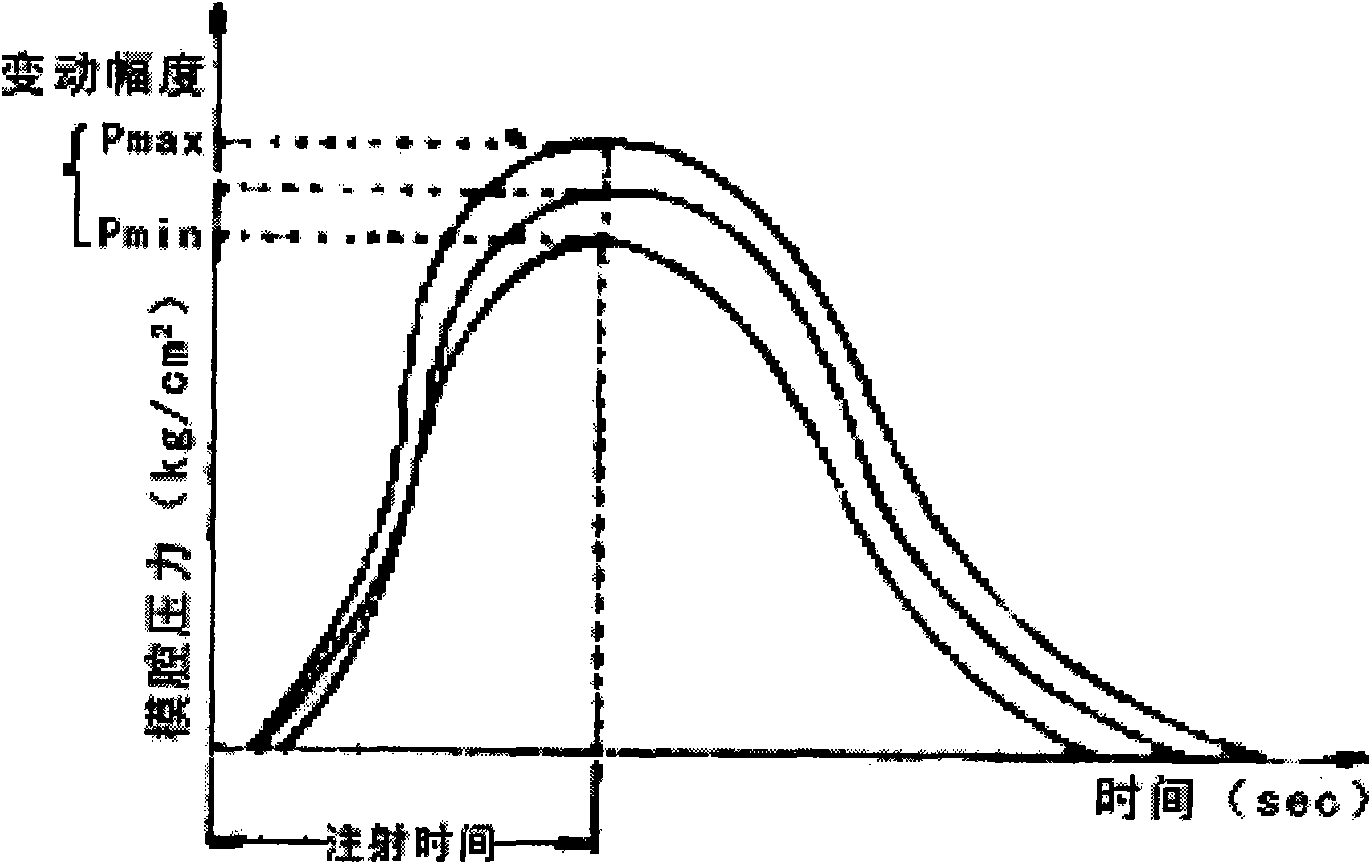

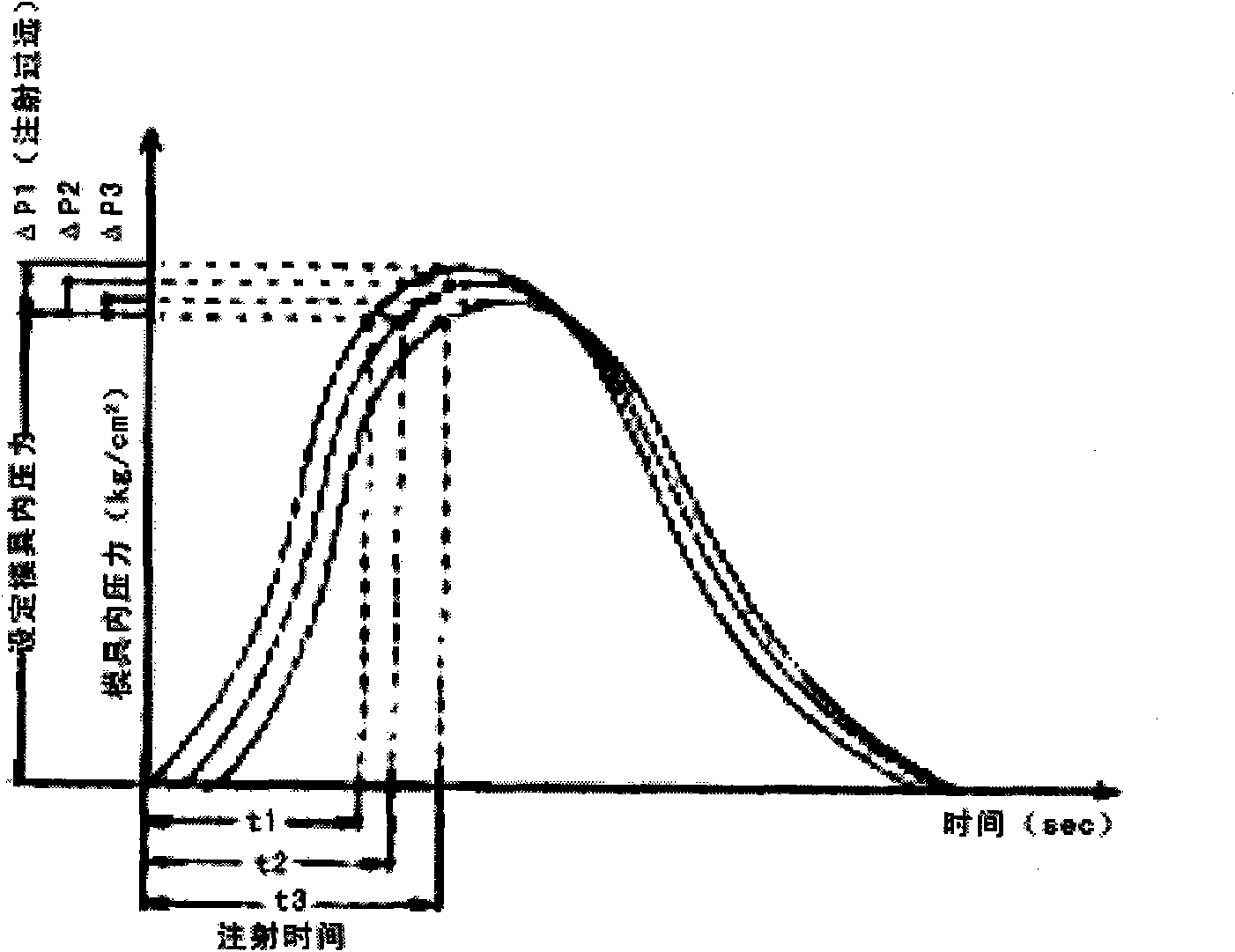

[0029] Step 2: Use the sensor to detect the cavity pressure before the cavity fully reaches the set value of the cavity pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com