Novel three-wheeled sliding plate whole-body body-building scooter

A sports car and three-wheel technology, applied in motor vehicles, bicycles, transportation and packaging, etc., can solve the problems of inability to achieve effective fitness in the upper limbs, inability to achieve effective fitness in the lower limbs, collisions, etc., achieve a reasonable and compact structure, and reduce the occupied space , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

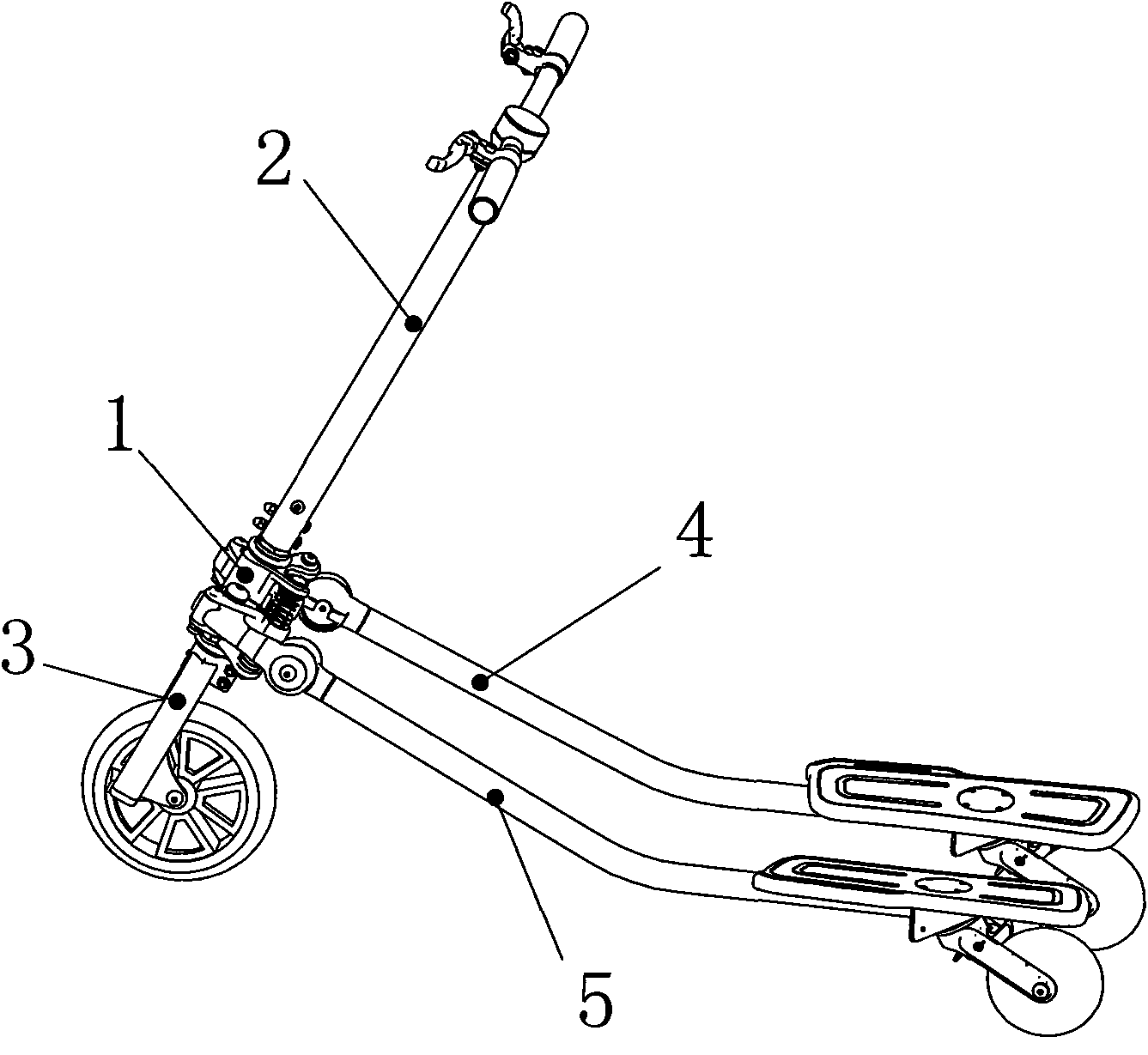

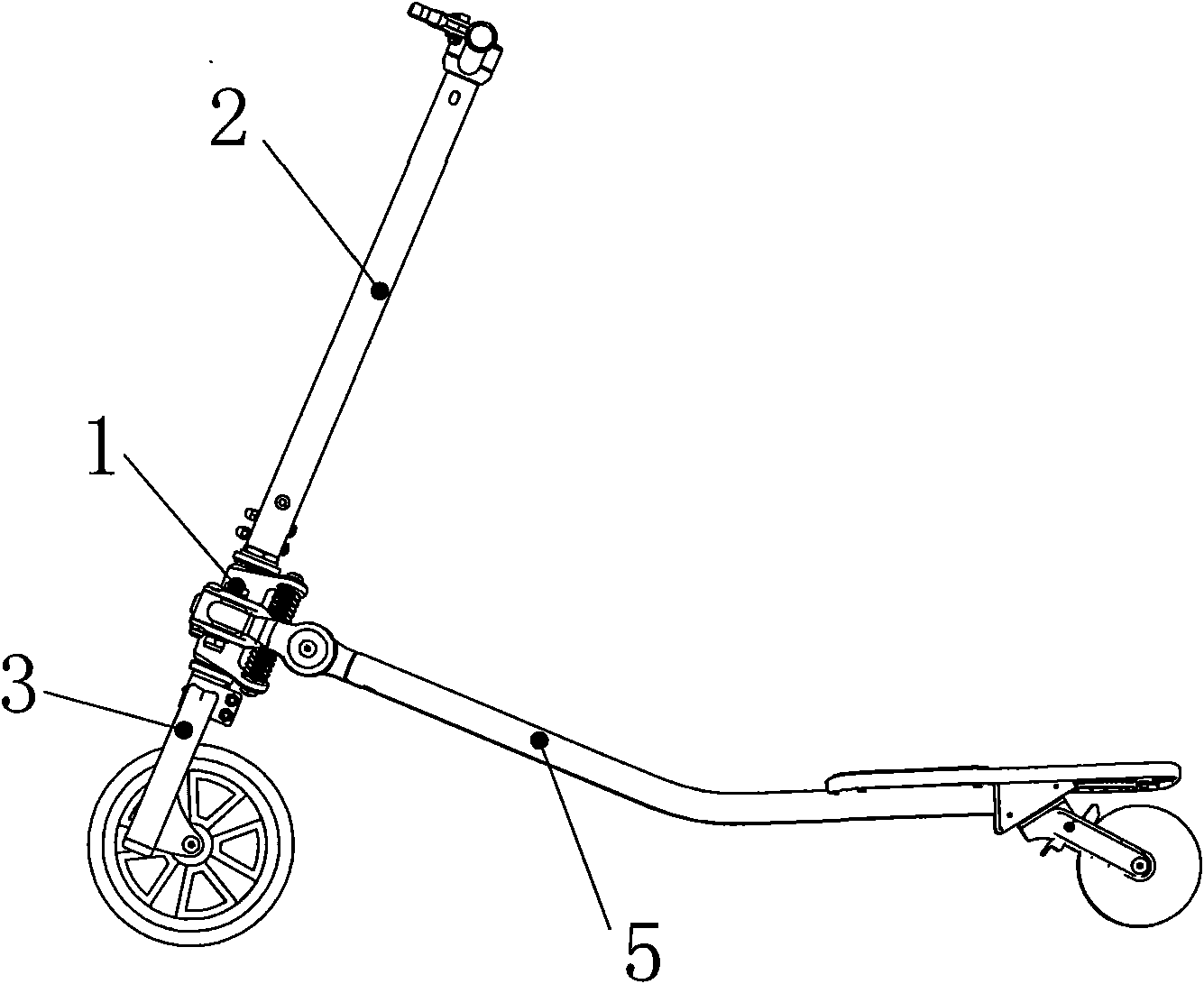

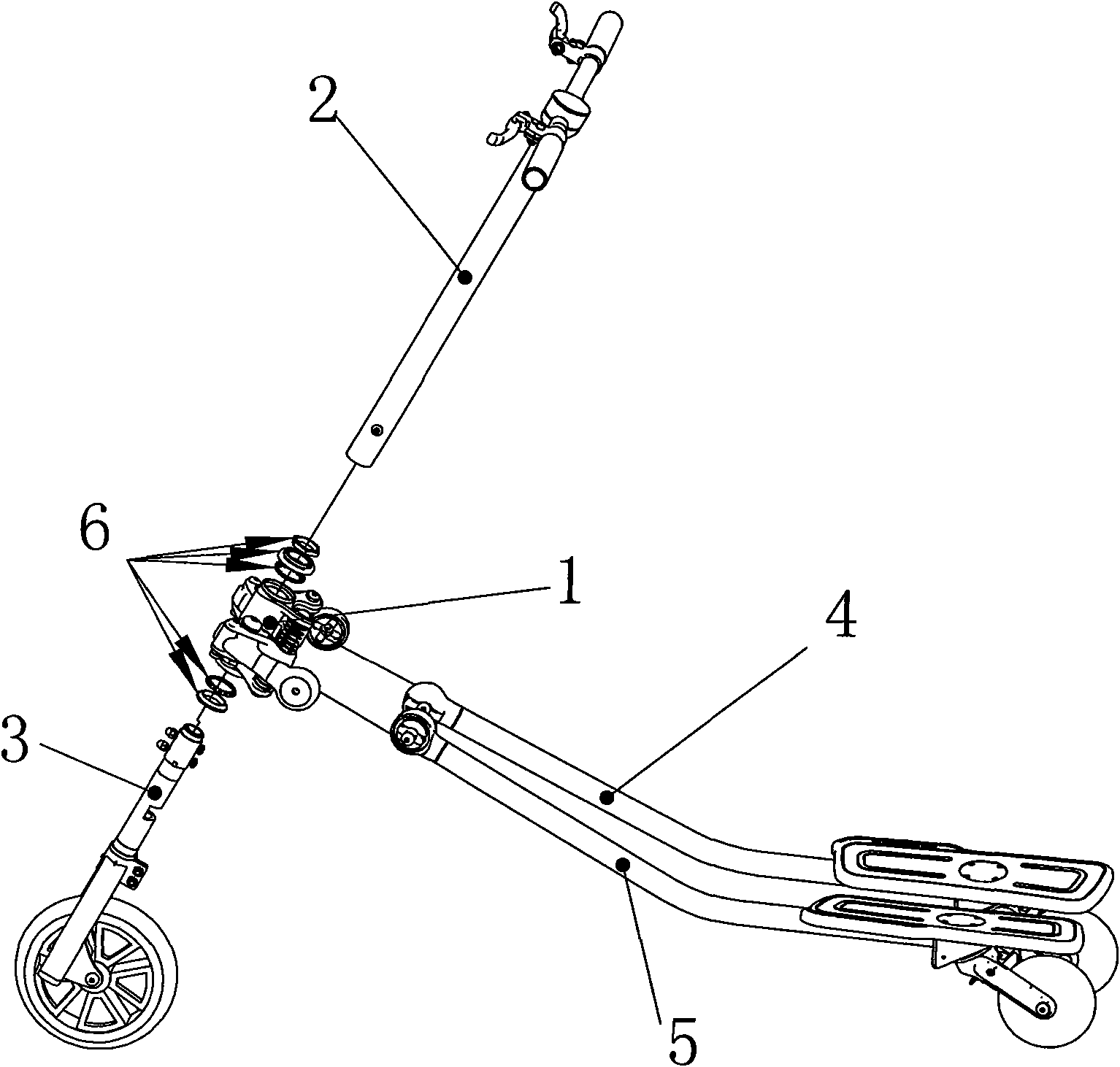

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 and image 3 As shown, the new three-wheeled skateboard body fitness sports car is mainly composed of six components: universal shaft structure 1, handle set 2, front fork set 3, right foot pedal set 4, left foot pedal set 5 and steel cup set 6 It is installed and combined, wherein the right pedal group 4 and the left pedal group 5 each have a pedal for standing on both feet, the handle group 2 has a handle for both hands, and the front fork group 3 has a Each of a front wheel and the right foot pedal group 4 and the left foot pedal group 5 has a rear wheel for rolling with the ground.

[0022] Cardan shaft structure, such as Figure 4 , Figure 5-1 , Figure 5-2 As shown, the spring support 8 is screwed into the thread of the head pipe 7 through the bolt 14 after pressing the bearing 13 and the inner pad 15, and the spring su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com