Novel film conveying method for packing machine

A technology of packaging machinery and film, applied in the field of packaging machinery, can solve the problem of difficulty in using special rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

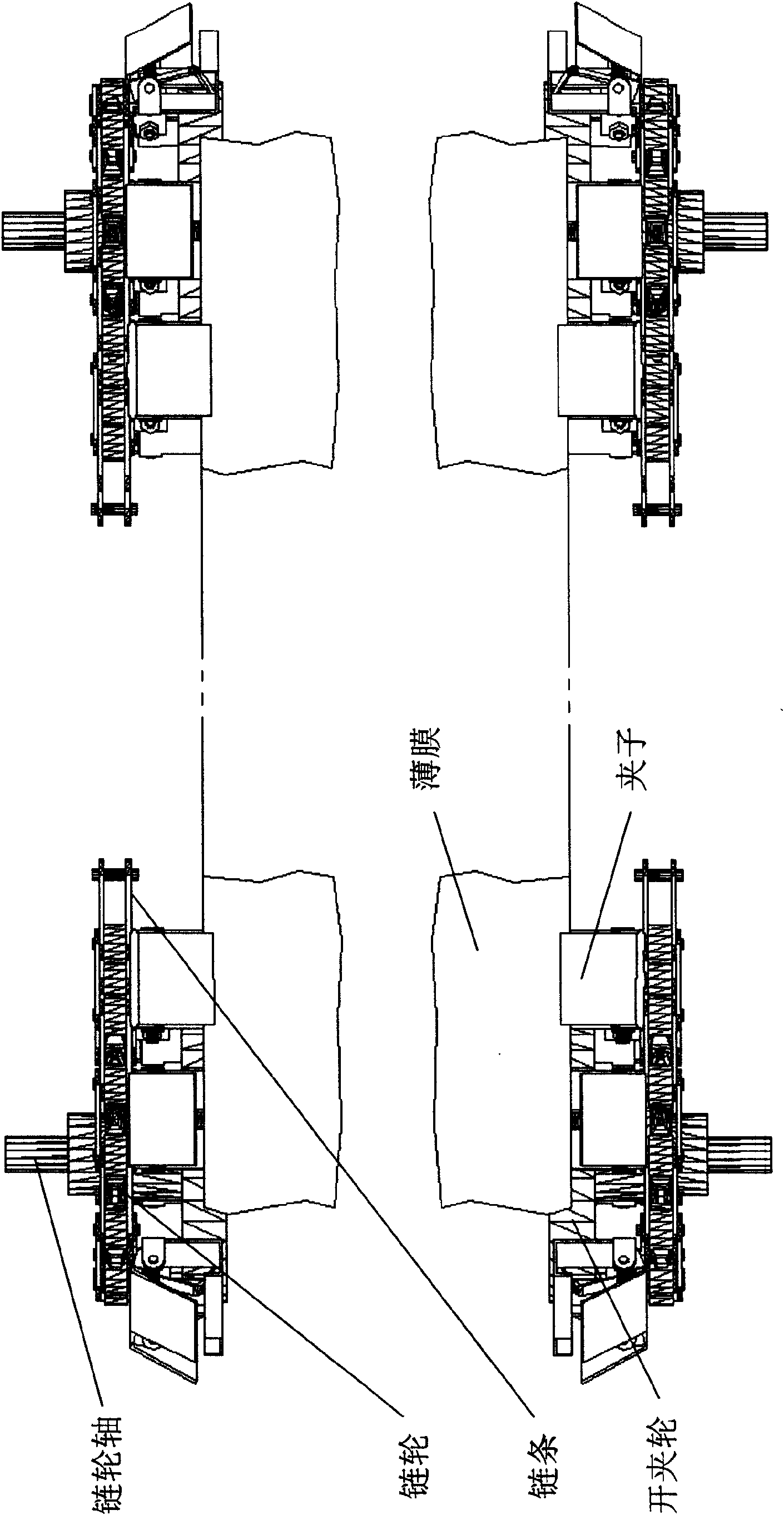

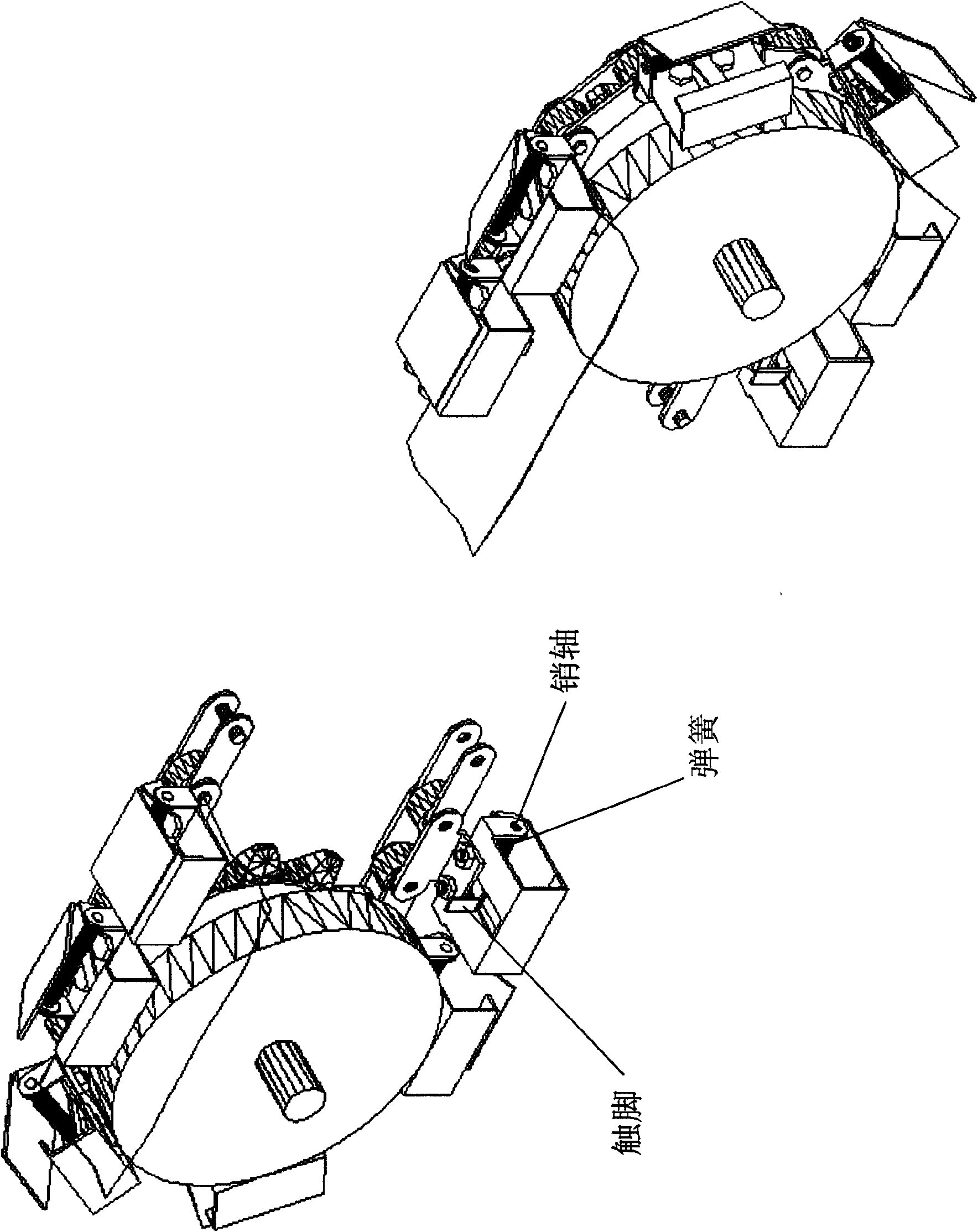

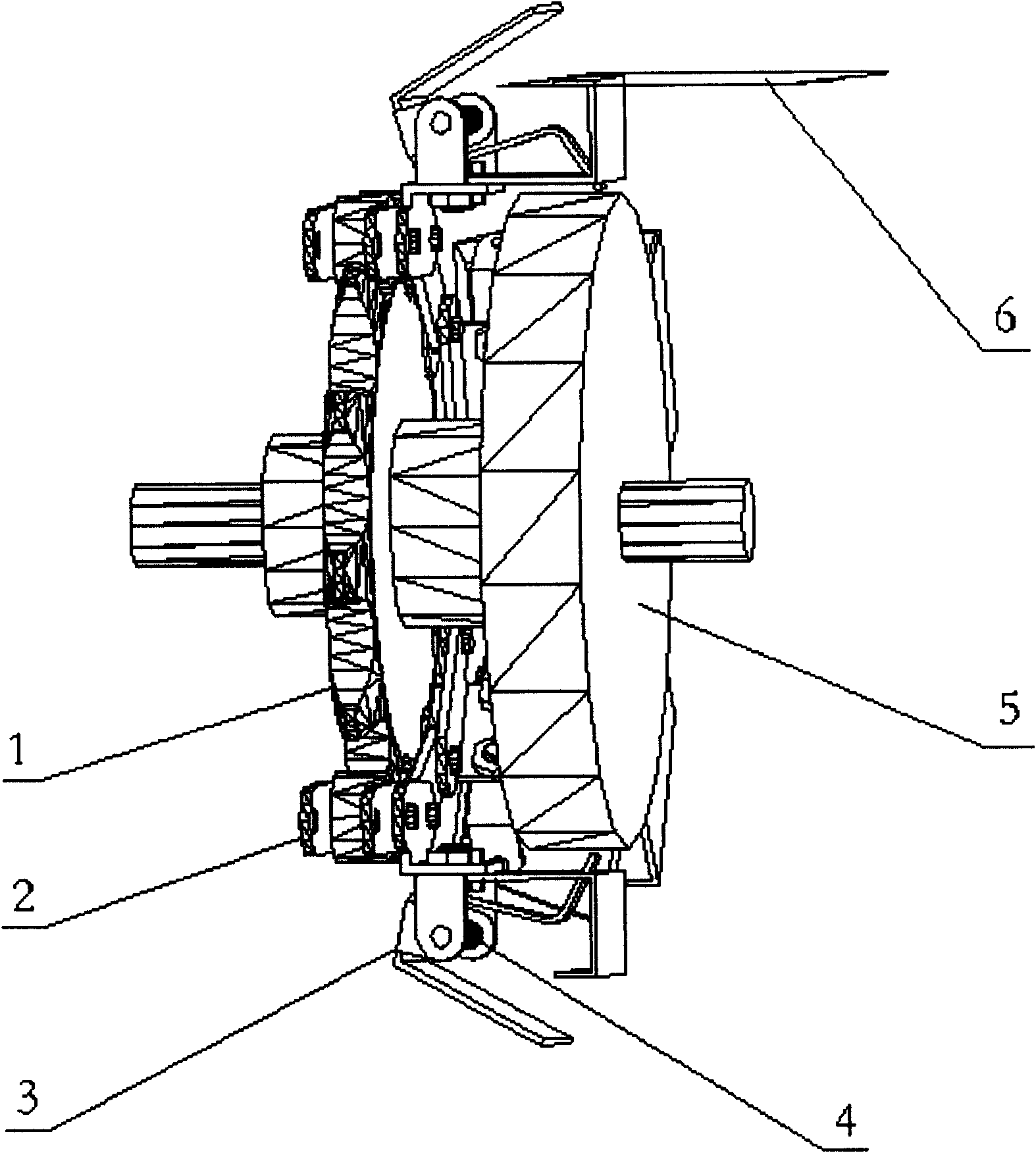

[0008] The delivery method is structured as figure 1 and figure 2 As shown, the implementation of the delivery method is as follows image 3 and Figure 4 shown. When working, the motor intermittently drives the sprocket 1 to rotate, thereby driving the conveyor chain 2. The clip 3 was originally in a closed state under the action of the spring 4. When it moved to a position in contact with the periphery of the clip opening wheel 5 along with the conveying chain, the periphery of the clip opening wheel pressed the contact feet under the clip, thereby overcoming the pressure of the spring 4, so that The upper cover of the clip rotates around the pin shaft, and the clip is thus gradually opened. When the conveyor chain drives the clip to move directly above the opening wheel, the upper cover of the clip is in a fully opened state, and the edge of the jaw moves a horizontal distance d to the outside of the chain, and creates a distance c from the outer edge of the film, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com