Breathing apparatus for normal pressure storage tank

A breathing device and storage tank technology, which is applied in packaging, transportation, packaging, containers, etc., can solve problems such as direct damage impact, easy to adhere to materials, easy to block, etc., to reduce production and maintenance costs, improve explosion protection, and improve safe use rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

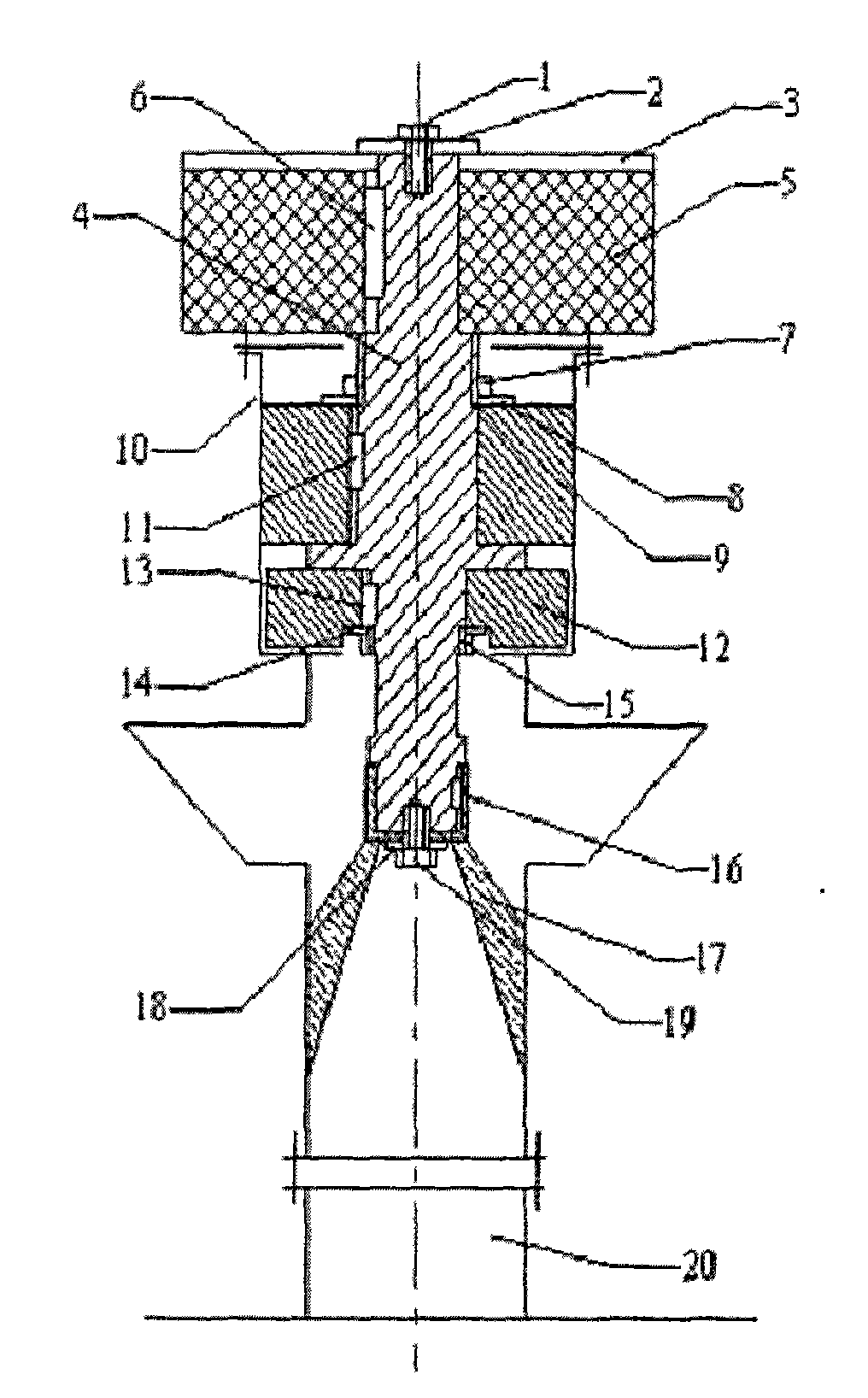

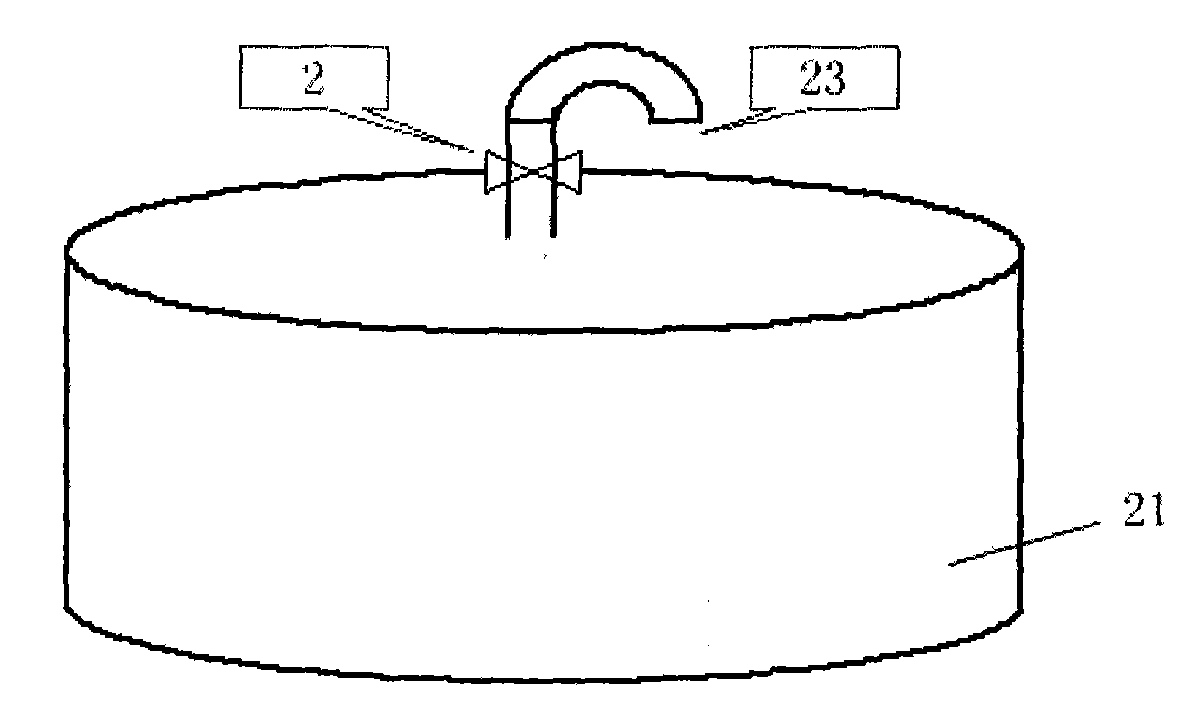

[0042] The atmospheric pressure storage tank breathing device of the present invention is installed on the top of 6 large tar tanks of 4500 cubic meters and 6 large ammonia water tanks in the tank area of a certain coking coal gas refining plant. The atmospheric pressure storage tank breathing apparatus includes:

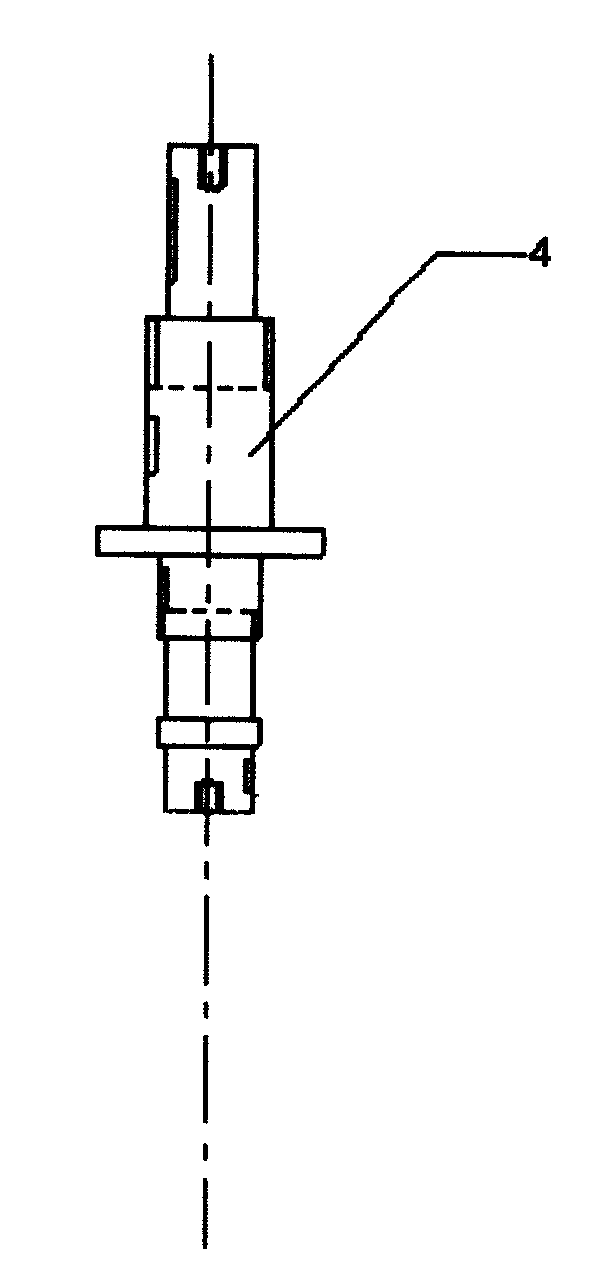

[0043]The fan blade box 5 with built-in fan blades and its transmission mechanism, the sliding bearing connection mechanism that is connected to the fan blades of the fan box 5, that is, the transmission box 10, is in transmission connection with the sliding bearing connection mechanism, that is, the transmission box 10 The hole-type flow-disturbing spiral scraper 17 runs through the above-mentioned mechanism and the ventilation pipe group of the normal-pressure storage tank ventilation pipe. The hole-type flow-disturbing spiral scraper 17 is provided with micropores on the flow-disturbing spiral scraper.

[0044] Among them, some components such as the spoiler sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com