Vertical anaerobic process tank integrated triphase separator

An anaerobic treatment, three-phase separator technology, applied in the field of vertical anaerobic treatment tank integrated three-phase separation device, can solve the problems of loss of anaerobic bacteria, turbidity of effluent, poor resistance to shock load, etc., and achieves convenient operation. , The effect of low infrastructure cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

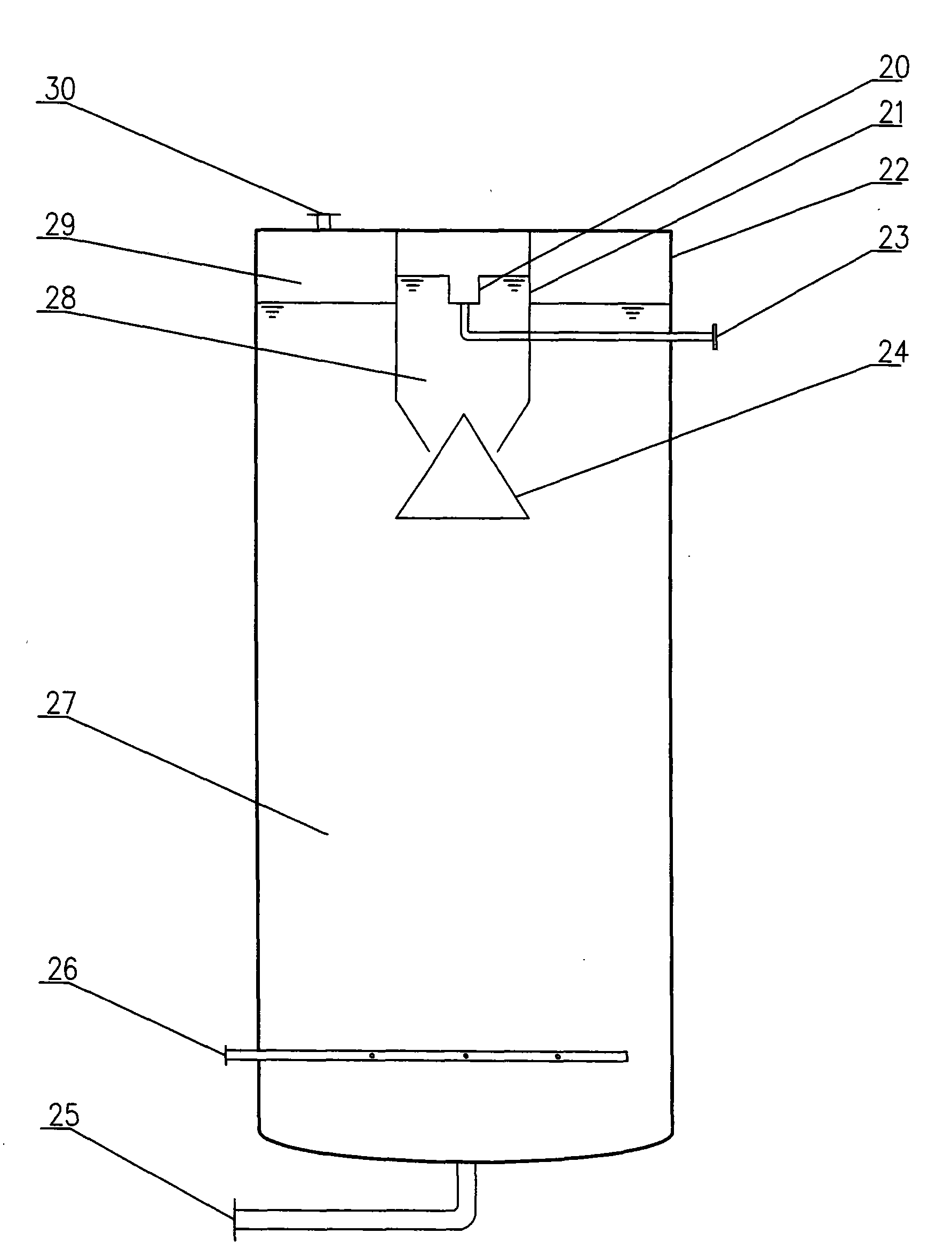

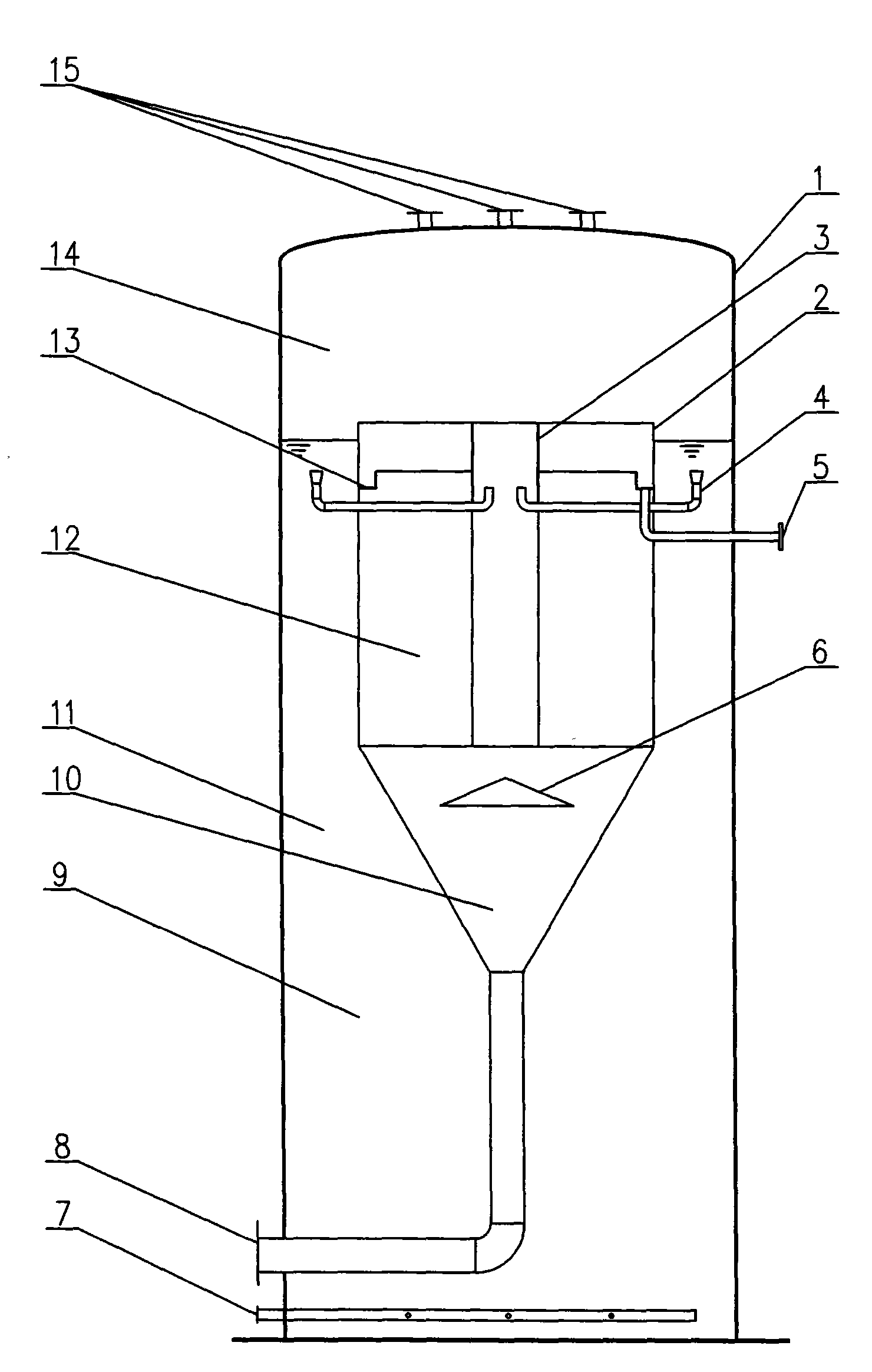

[0020] like figure 2 As shown, it is a schematic diagram of a vertical anaerobic treatment tank integrated three-phase separator. The vertical anaerobic treatment tank integrated three-phase separator consists of a vertical anaerobic tank 1, a sedimentation tank 2, and a vertical enhanced gas-liquid Separation device 3, guide pipe 4, water outlet pipe 5, reflector 6, water inlet pipe 7, mud discharge pipe 8, reaction zone 9, mud bucket 10, gas-liquid separation zone 11, sedimentation zone 12, water collecting tank 13, gas collecting The chamber 14 and the exhaust port 15 are composed.

[0021] The top of the vertical anaerobic tank 1 is provided with an exhaust port 15, the inner upper side of the vertical anaerobic tank 1 is provided with a gas collection chamber 14 with a height of 1.2-1.5 m, and the bottom of the vertical anaerobic tank 1 is provided with an inlet. Water pipe 7, a sedimentation tank 2 is provided in the lower middle of the gas collecting chamber 14, a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com