Efficient combined method oil-containing sludge cleaning system

A technology of cleaning system and combination method, which is applied in the field of high-efficiency combination method oily sludge cleaning system, which can solve the problems of ecological environmental hazards, cleaning water needs to be desalted, and increase treatment costs, so as to achieve reasonable allocation of economic resources and reduce separation residence time , Realize the effect of recycling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

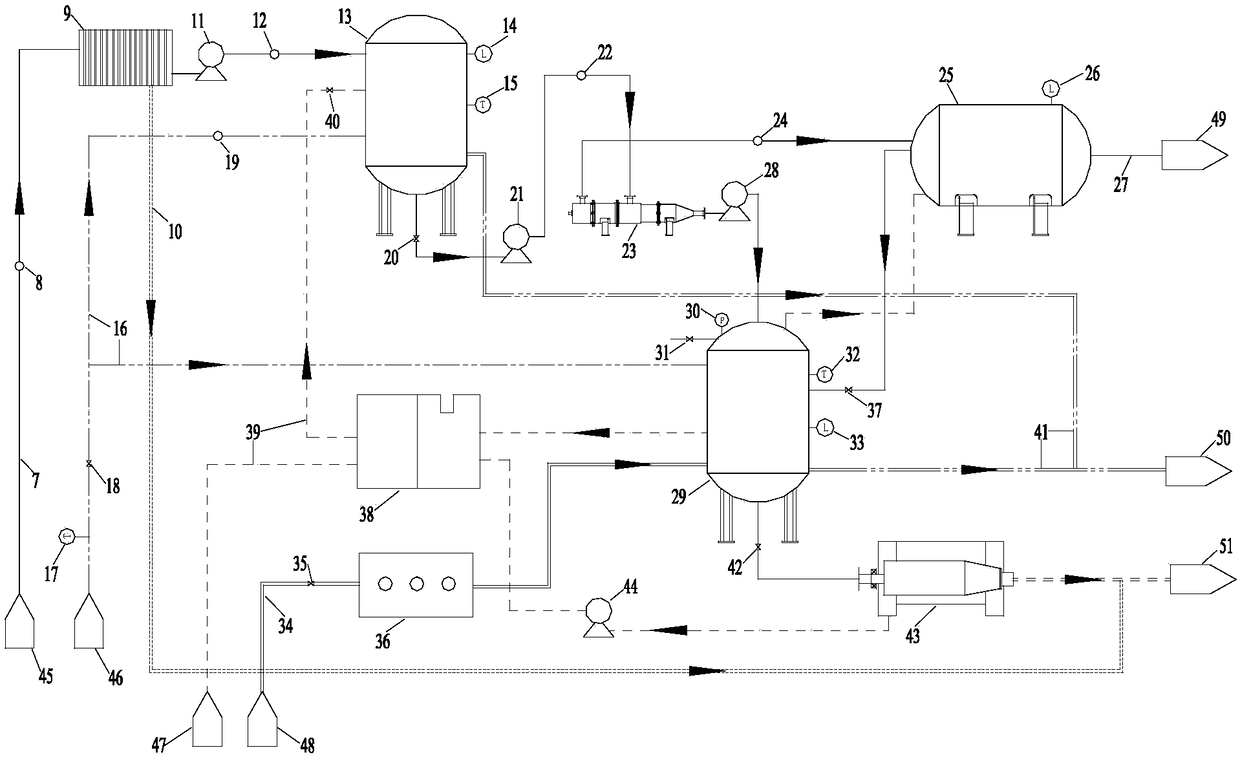

[0055] Such as figure 1As shown, the high-efficiency combined oily sludge cleaning system of this embodiment includes: conditioning device 1, mechanical separation device 2, ozone auxiliary cleaning device 3, oil-water separation device 4, mud-water separation device 5 and cleaning water reuse device 6 The oily sludge 41 is connected to the grid 9 through the oily sludge input pipeline 7, the single screw pump 11 is connected to the heating and stirring tank 13, and the steam 42 is connected to the heating and stirring tank 13 through the steam input pipeline 16, and the heating and mixing tank 13 is output through steam The pipeline 41 is connected to the steam treatment device 50, and the oily sludge is tempered through the grid 9 and the heating and stirring tank 13; Mechanically separate the oily sludge, the mechanical separation device 2 is connected to the ozone auxiliary cleaning device 3 and the oil-water separation device 4 respectively; the oil-water separation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com