Elbow Coalescing Three-Phase Cyclone Separator

A cyclone separator and elbow technology are applied in cyclone devices, devices whose axial directions of cyclone can be reversed, etc., which can solve the problems of lower oil-water separation efficiency, increase separation treatment costs, etc., and improve the situation of liquid inclusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings:

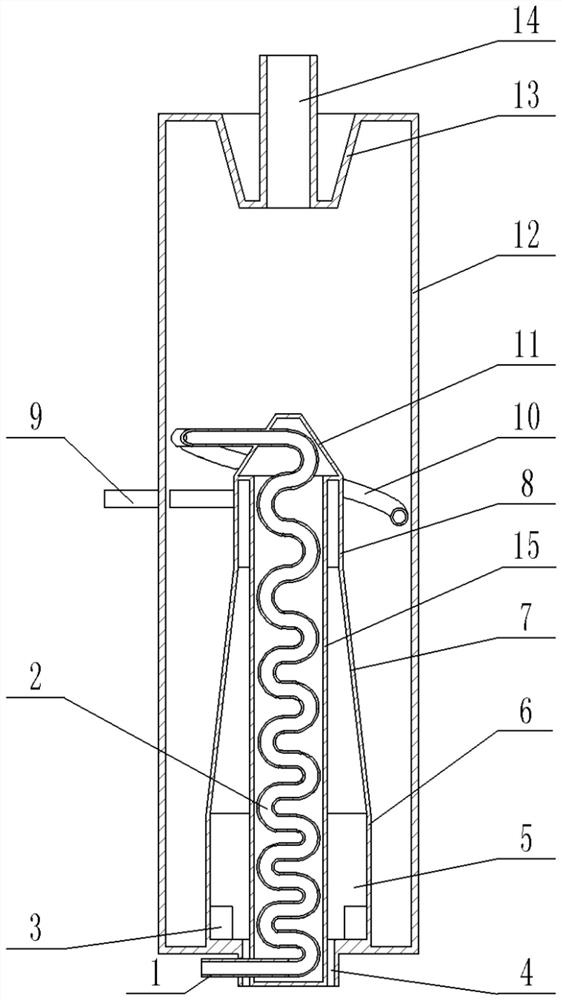

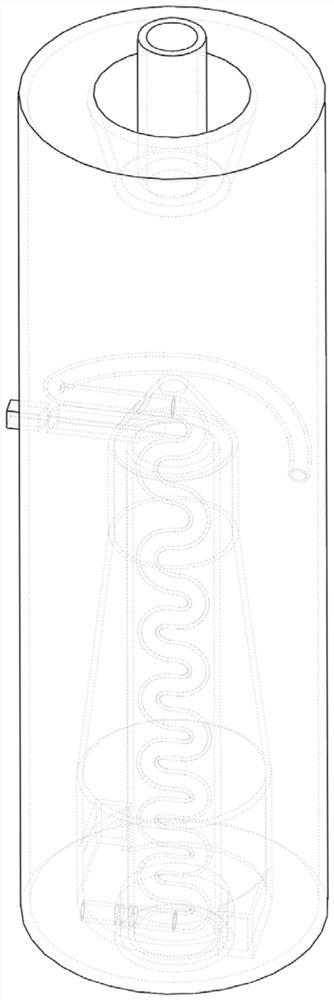

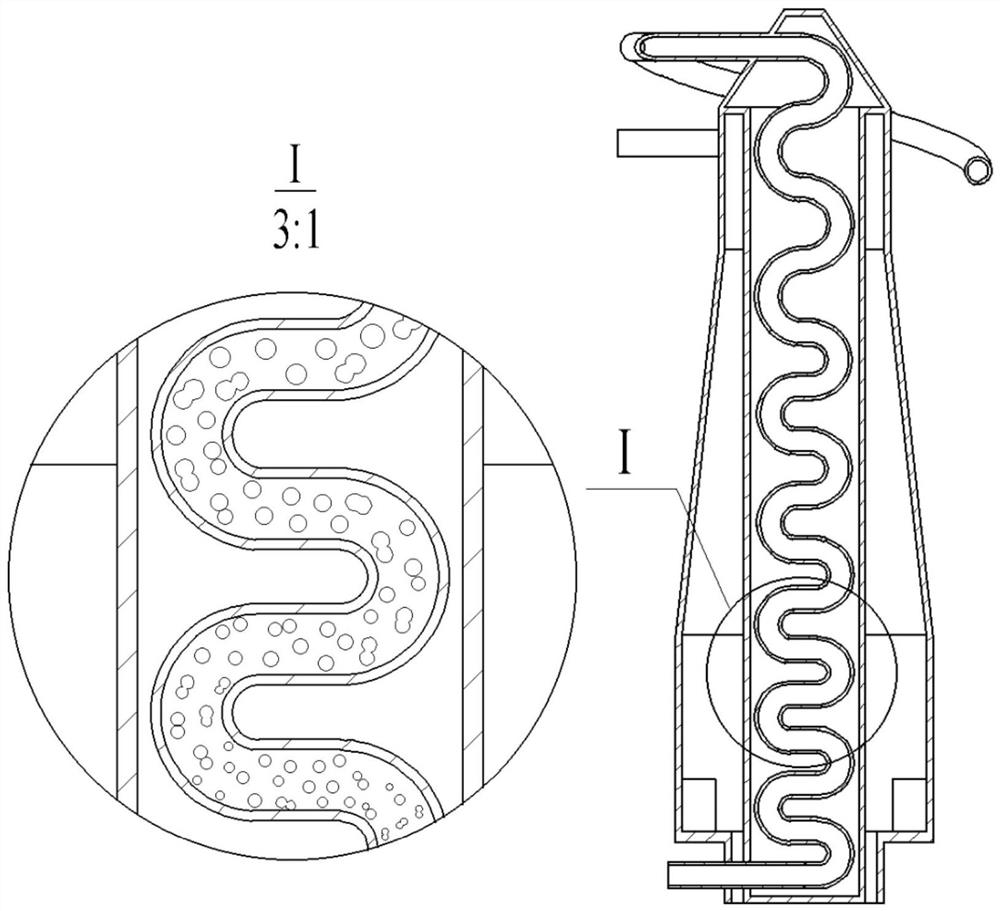

[0021] like Figure 1 to Figure 6 As shown, this elbow coalescing three-phase cyclone is an integrated separation device, which is mainly composed of an outer cylinder 12, an inner cylinder 5, a coalescing elbow 2, and a coalescing elbow conduit 10. The inner cylinder is mainly composed of double tangential inlet 3, swirl section 6, cone section 7, bottom flow section 8, small round table 11, annular oil phase outlet 4, water phase outlet 9, spacer 15 and other parts, and the outer cylinder is mainly composed of gas phase. The outlet 14 is composed of a large circular platform 11, and the outer wall of the inner cylinder and the inner wall of the outer cylinder form a gas-liquid separation space.

[0022] The outer cylinder is a cylindrical structure, a hole is opened in the middle part of the side of the outer cylinder 12, and the water phase outlet 9 protrudes from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com