Steel skeleton connecting positioning piece in decoration for vertical face of outer wall of building

A technology of steel skeleton and wall facade, applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of complicated process, slow construction speed, and reduced thermal insulation effect, and achieve easy position adjustment, easy installation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

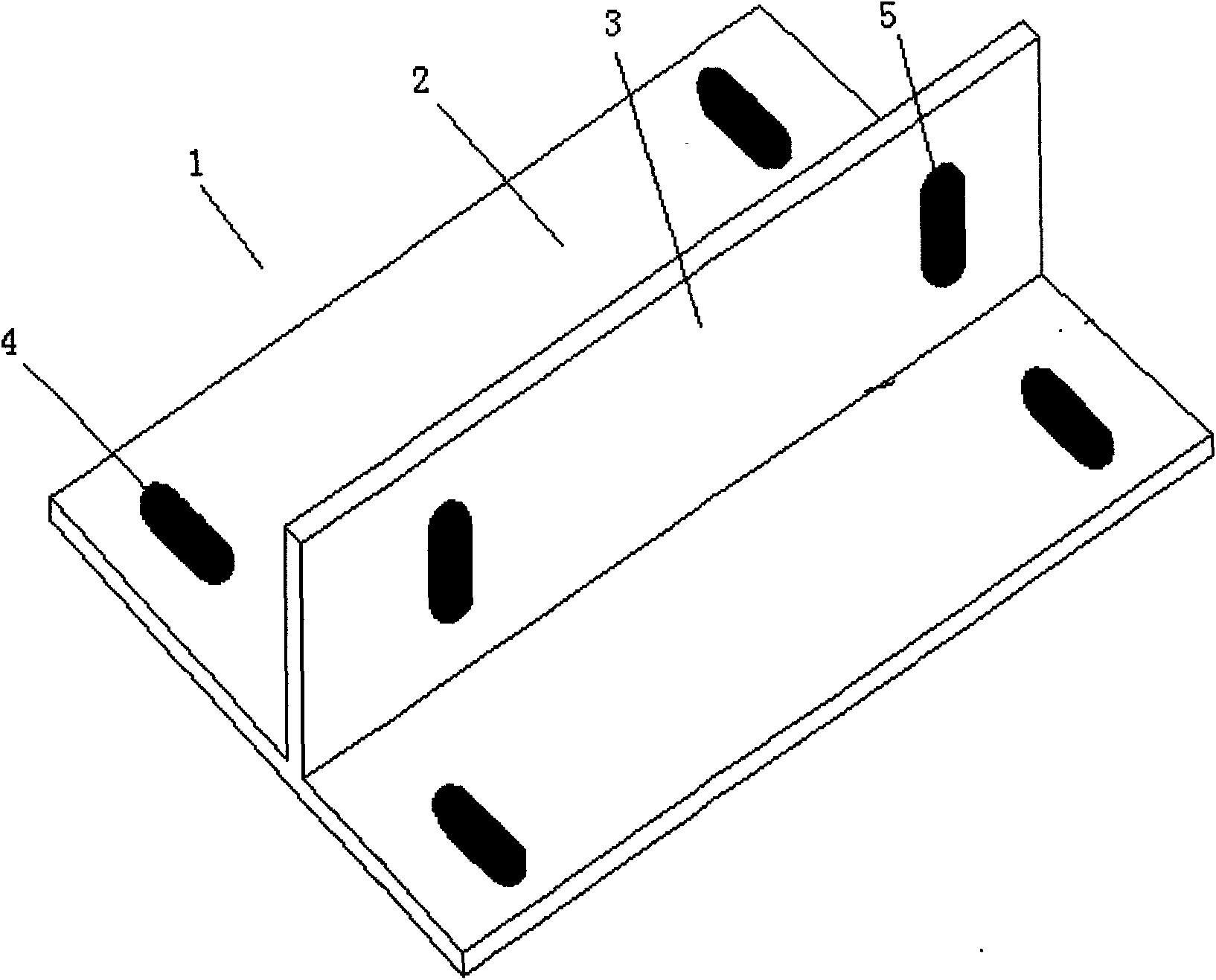

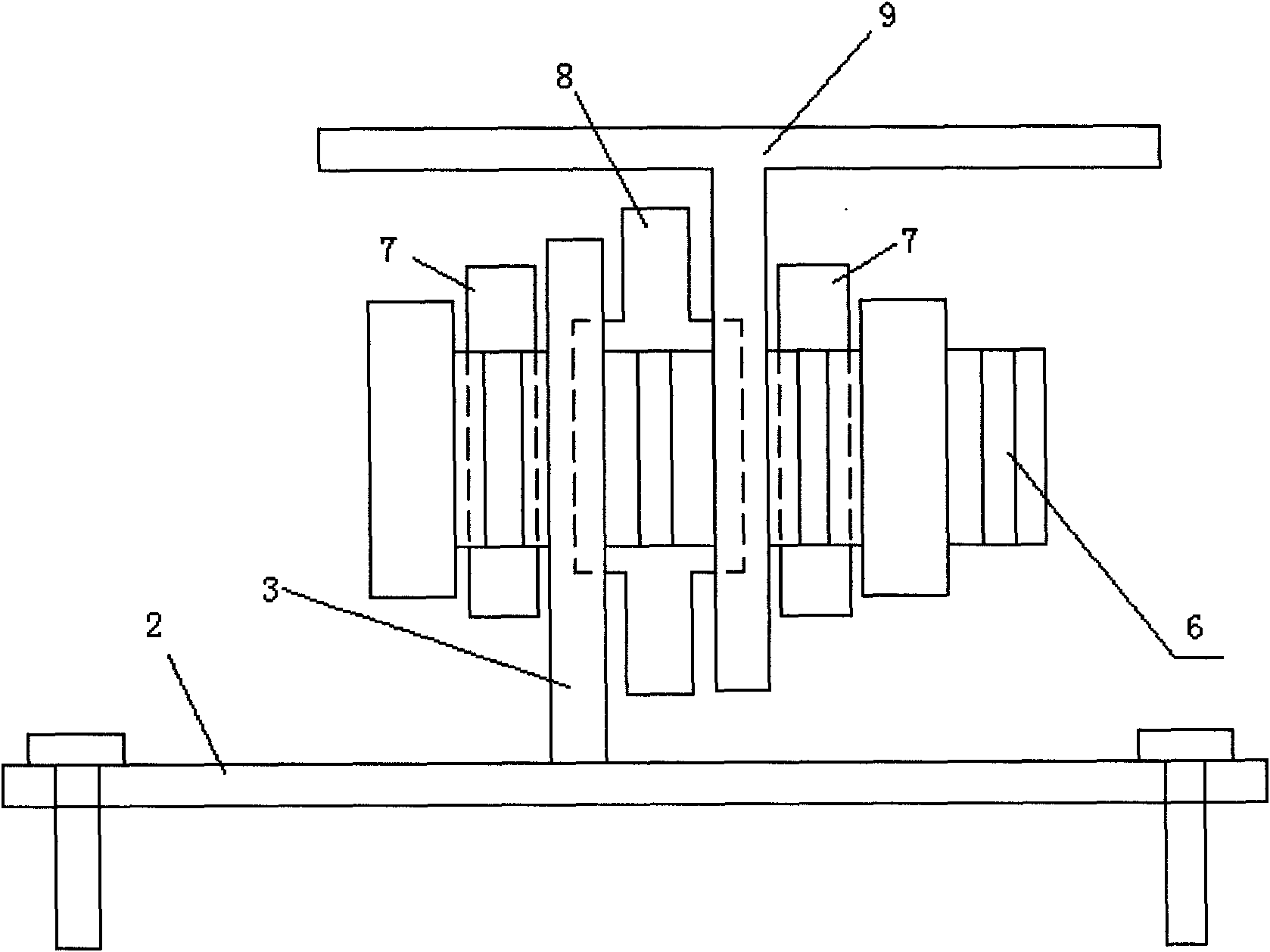

[0015] The connector 1 is pre-embedded in the wall of the main structure. At this time, the wall connecting steel plate 2 and the skeleton connecting steel plate 3 of the connector 1 are divided into two installations. First, during the wall construction of the main structure, the wall connecting steel plate 2 is pre-embedded in the main body, and then the skeleton connecting steel plate 3 is welded to the wall connecting steel plate 2 pre-embedded in the wall.

Embodiment 2

[0017] Rear type, after the main structure is completed, the prepared connectors, including the wall connecting steel plate 2 and the skeleton connecting steel plate 3, are connected to the main body with bolts 6 through the wall connecting bolt holes 4 on the wall connecting steel plate 2.

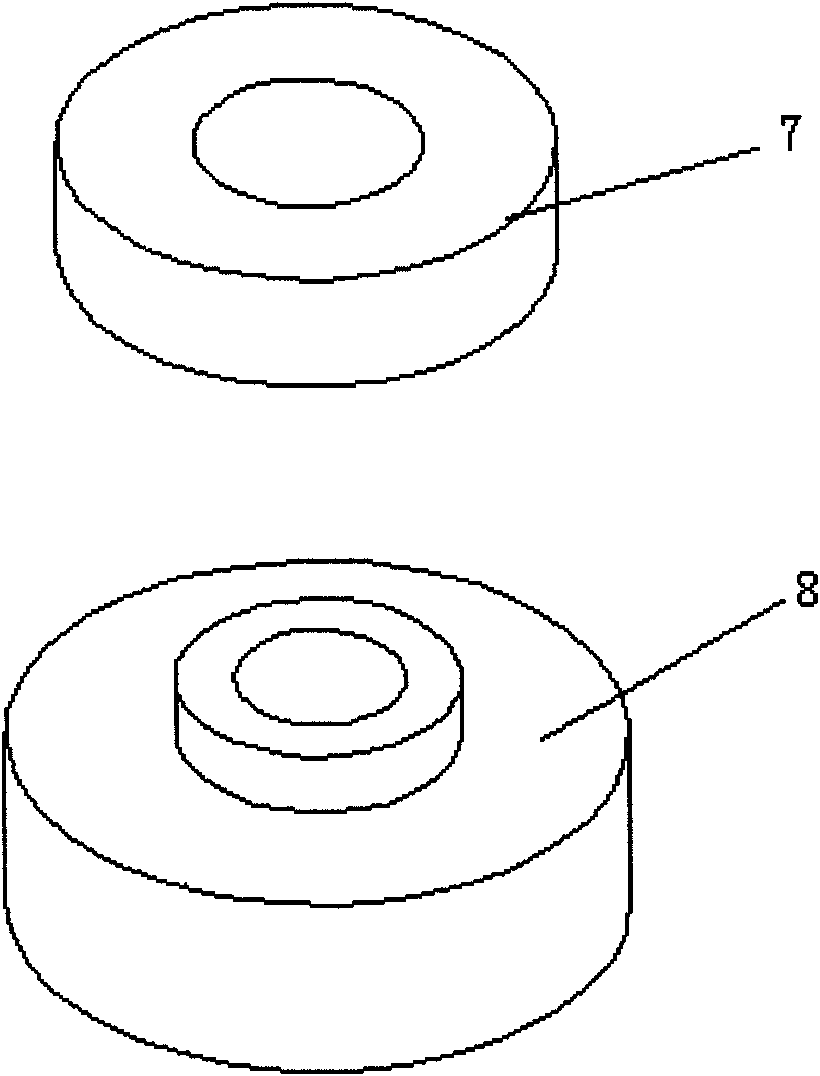

[0018] Two types of nylon washers are used for the steel skeleton connection and positioning parts in the facade decoration of building exterior walls, one is ordinary nylon washers 7, and the other is nylon washers 8 protruding from the middle of the contact surface; the nylon washers 8 protruding from the middle of the contact surface are installed on On the bolt between the skeleton connection steel plate 3 and the steel skeleton 9, one side of the protruding part is placed in the skeleton connection bolt hole 5, and the other side is placed in the bolt hole on the steel skeleton 9; when the bolt 6 is connected with the steel skeleton 9 and the skeleton Other contact places of steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com