Hydraulic controlling system for mining concrete pump

A hydraulic control system and concrete pump technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as potential safety hazards, affecting the service life of motorized valves and bumpers, complex mechanical structures, etc., and achieve cost savings Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

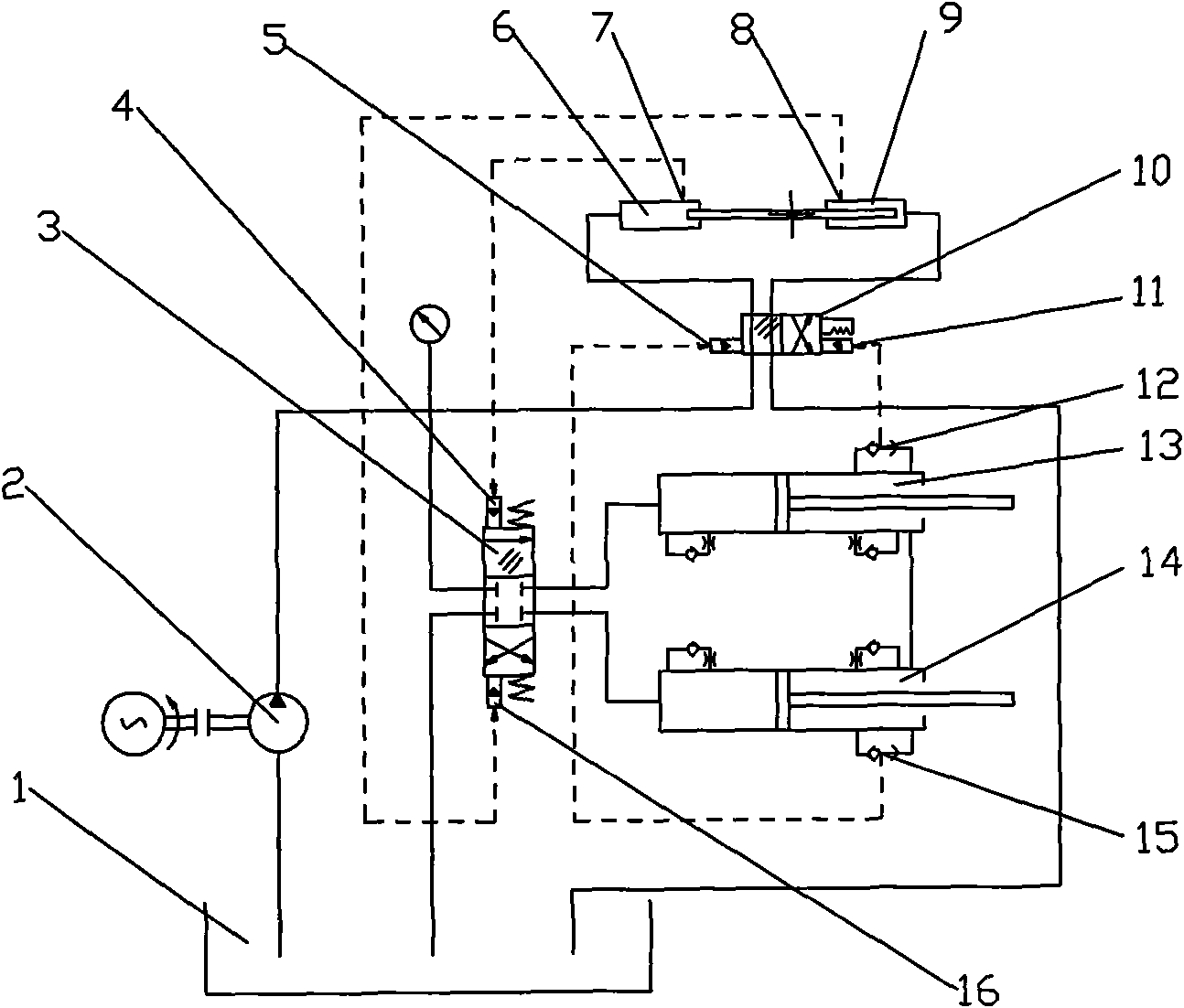

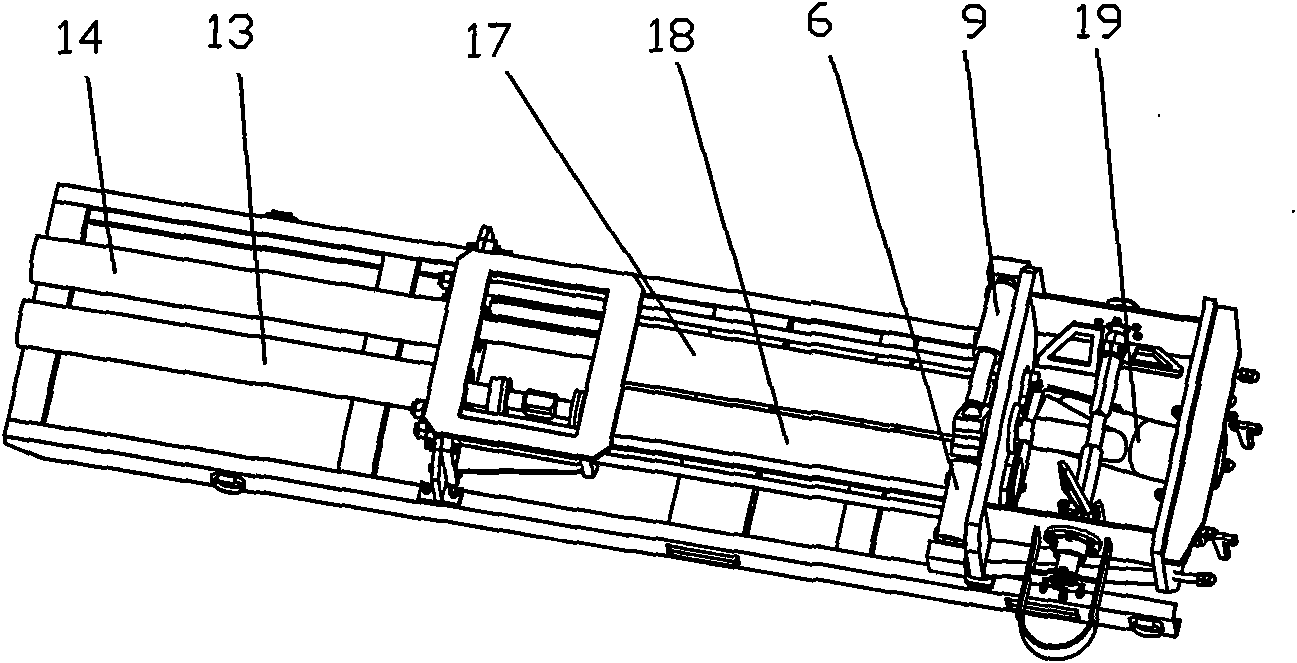

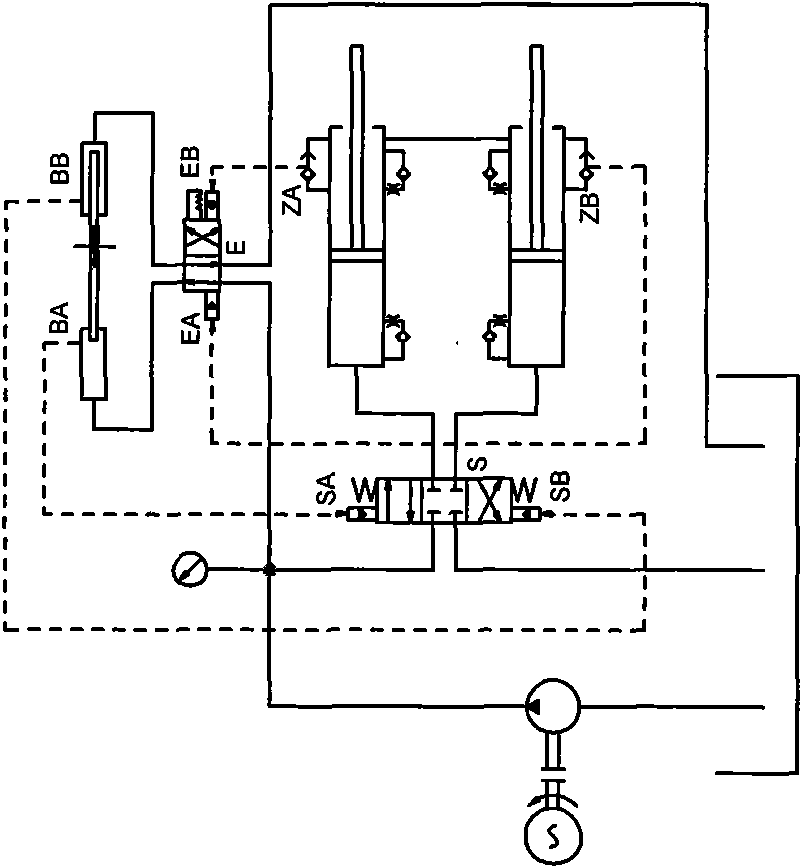

[0019] like figure 1 , 2 Shown, the present invention comprises oil tank 1, pump 2 (explosion-proof motor 20 drives pump 2), drives concrete cylinder A18, concrete cylinder B17 master oil cylinder A13, master oil cylinder B14, and it also includes driving S pipe 19 in concrete cylinder A18, Swing cylinder A6, swing cylinder B9 for swing switching between cylinder ports of concrete cylinder B17, three-position four-way hydraulic control reversing valve S3, two-position four-way hydraulic control reversing valve E10; swing cylinder A6 and swing cylinder B9 respectively set Control oil port BA7, control oil port BB8; control oil port ZA12 and control oil port ZB15 are set on the main oil cylinder A13 and main oil cylinder B14 respectively; Control oil port SA4 and control oil port SB16 are set on the control reversing device, and control oil port SA4 and control oil port SB16 are respectively connected with control oil port BA7 and control oil port BB8; There is a hydraulic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com