Creeper tread quality test device and test method thereof

A technology of testing equipment and track shoes, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as difficult quality and performance testing, and achieve the effect of improving detection speed and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

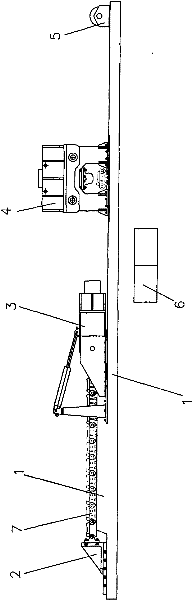

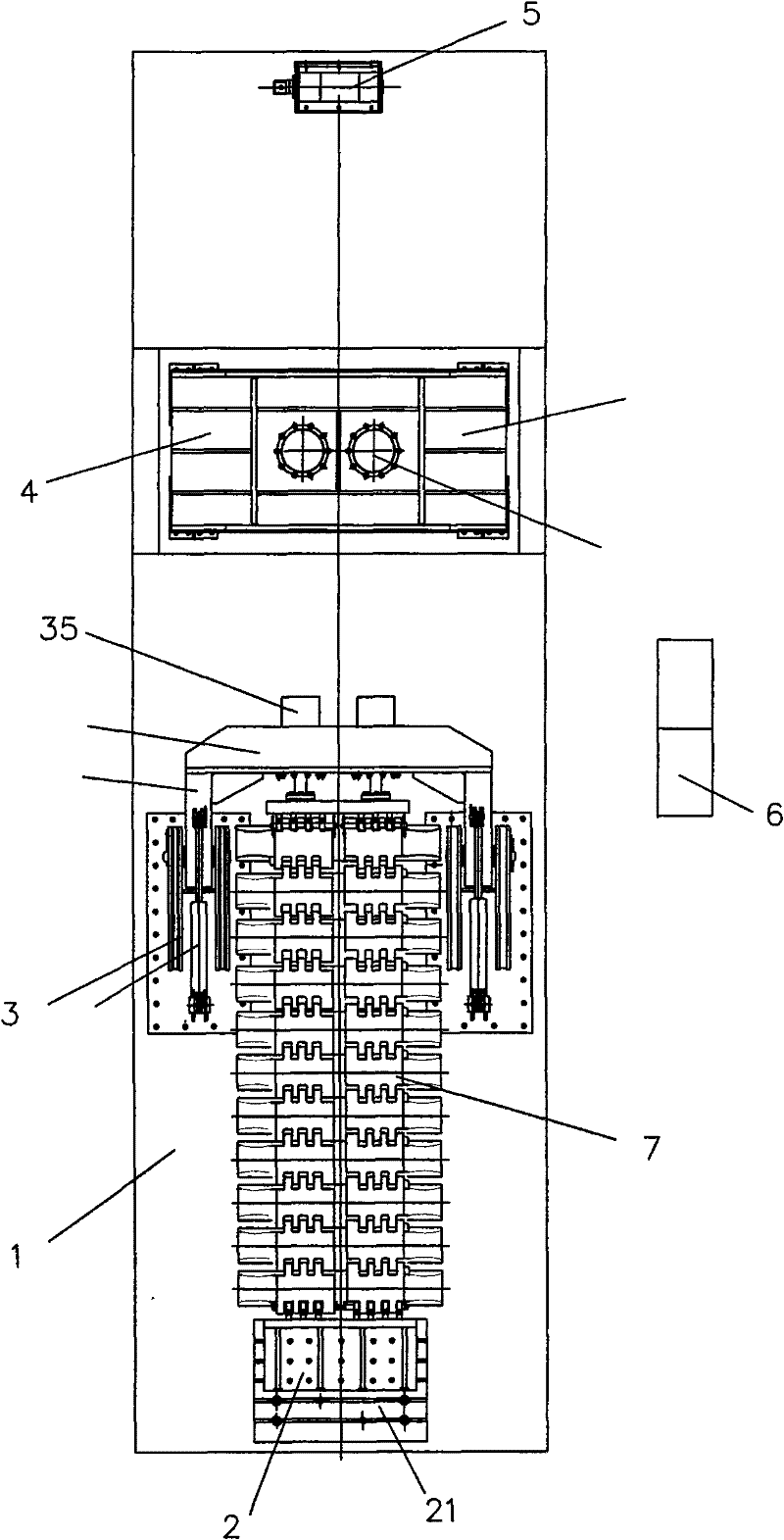

[0023] see figure 1 According to the present invention, a track shoe quality testing device includes a working platform 1 , a positioning device 2 , a tension testing device 3 , a pressure testing device 4 , a traction device 5 and a control device 6 . The positioning device 2 , the tension testing device 3 , the pressure testing device 4 and the traction device 5 are sequentially arranged in a straight line on the working platform 1 . The control device 6 is located on one side of the working platform 1 .

[0024] The work platform 1 is formed by laying steel plates on a reinforced concrete foundation.

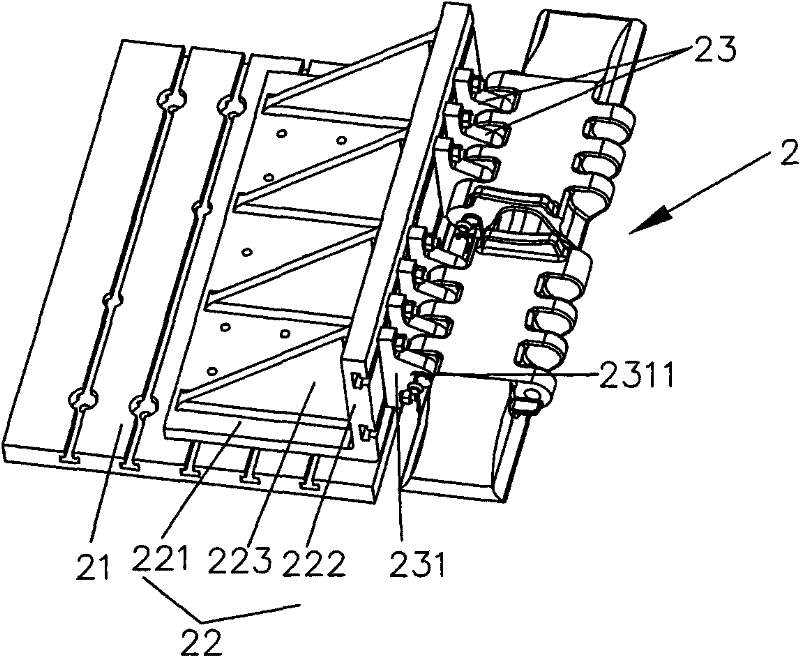

[0025] see figure 2 , image 3 , The positioning device 2 includes a positioning bottom plate 21 , a supporting plate 22 and a locking assembly 23 .

[0026] The positioning bottom plate 21 is installed on the working platform 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com