Method for manufacturing tube shell of traveling wave tube

A manufacturing method and technology for traveling wave tubes, which are applied in the manufacture of ships or lead-in wires, and tubes/containers of transit-time electron tubes, etc., can solve the problems of insufficient tube and shell accuracy, poor air tightness, etc., and achieve low cost, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

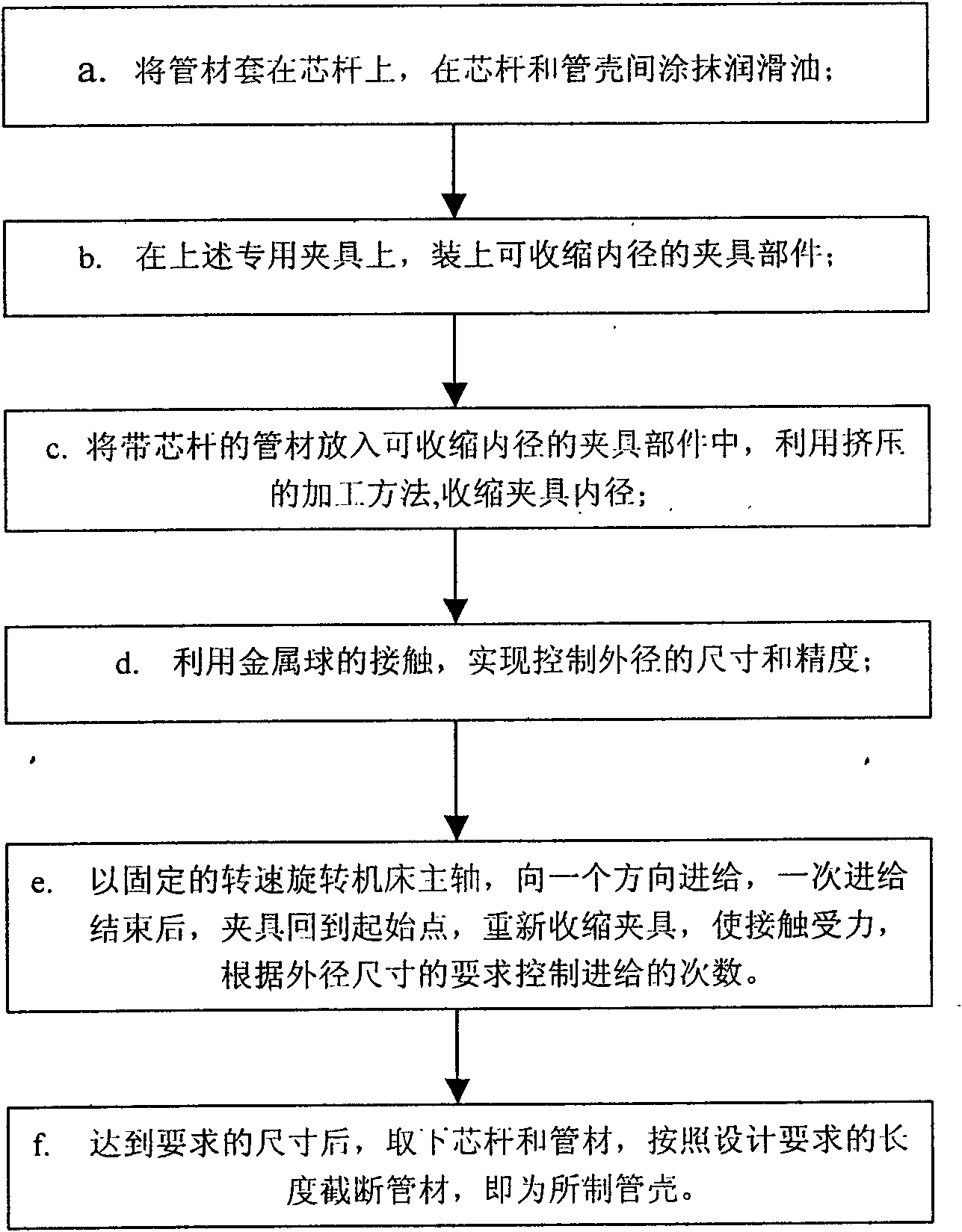

[0019] The principle of the technical scheme of the present invention is to use the pipe with a size margin, the inner diameter is guaranteed by the precision of the core rod, and the outer diameter is guaranteed by the extruded metal ball, so that the internal and external forces of the pipe are extruded and deformed, and at the same time, the length direction is ensured. Concentricity and dimensions.

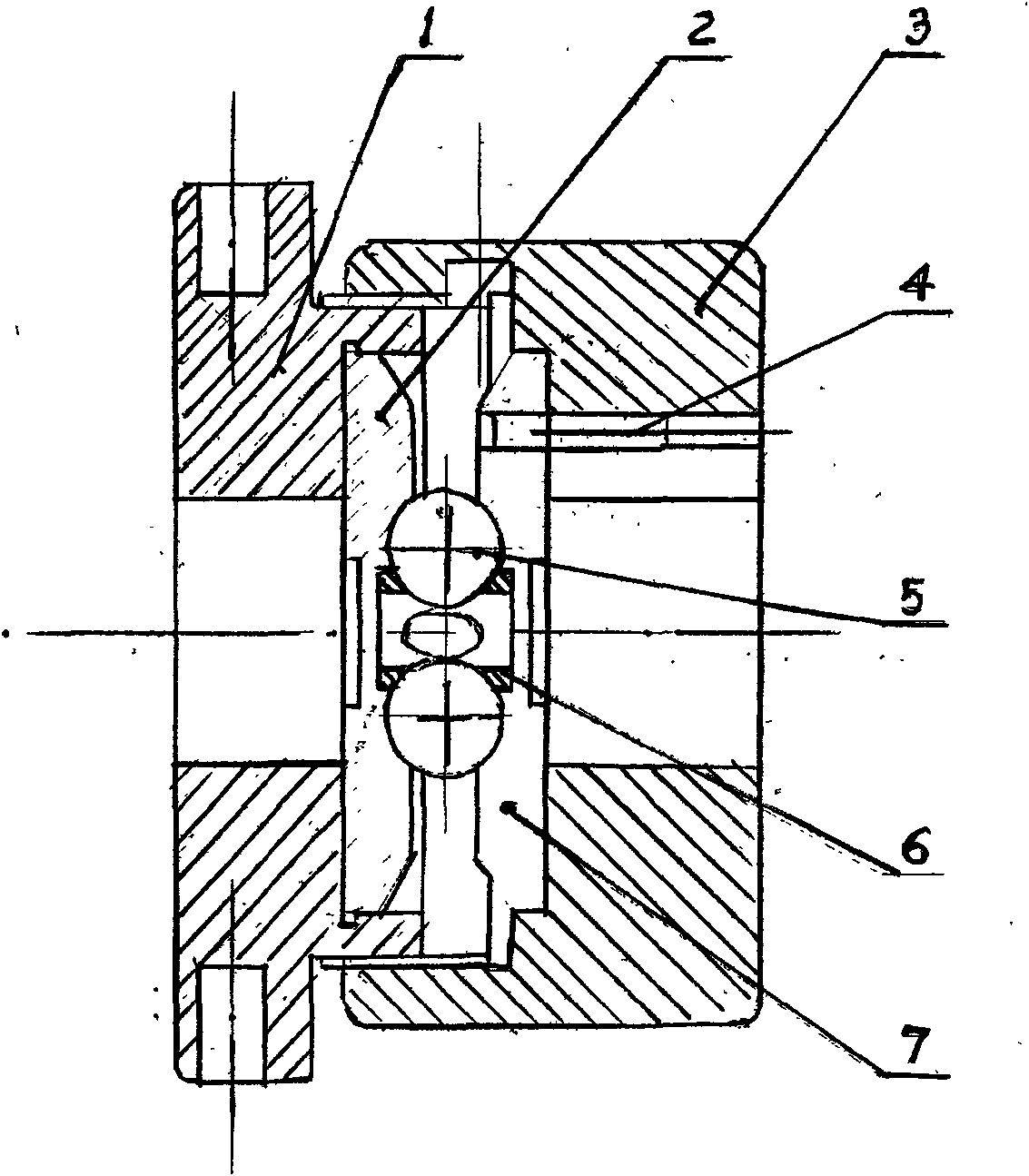

[0020] refer to figure 1 , showing the schematic diagram of the shrinkable inner diameter fixture. There are four high-strength and high-precision metal balls 5 in the shrinkable fixture described in the figure. gap;

[0021] When the fixture fixes the upper base 3, the lower base 1 is rotated to reduce the distance between the two, and drives the retractable lower pressing block 2 to move, reducing the gap between the retractable lower pressing block 2 and the retractable upper pressing block 7, 4 is Operate the air hole of the fixture, the slopes of 2 and 7 drive the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com