Ultrathin microwave antenna with ultra high performance

An ultra-high-performance, microwave antenna technology, applied to antennas, waveguide horns, electrical components, etc., can solve the problems of inconvenient installation and transportation, increased antenna cost, thick antenna, etc., and achieve the effect of simple structure, high antenna efficiency, and increased gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

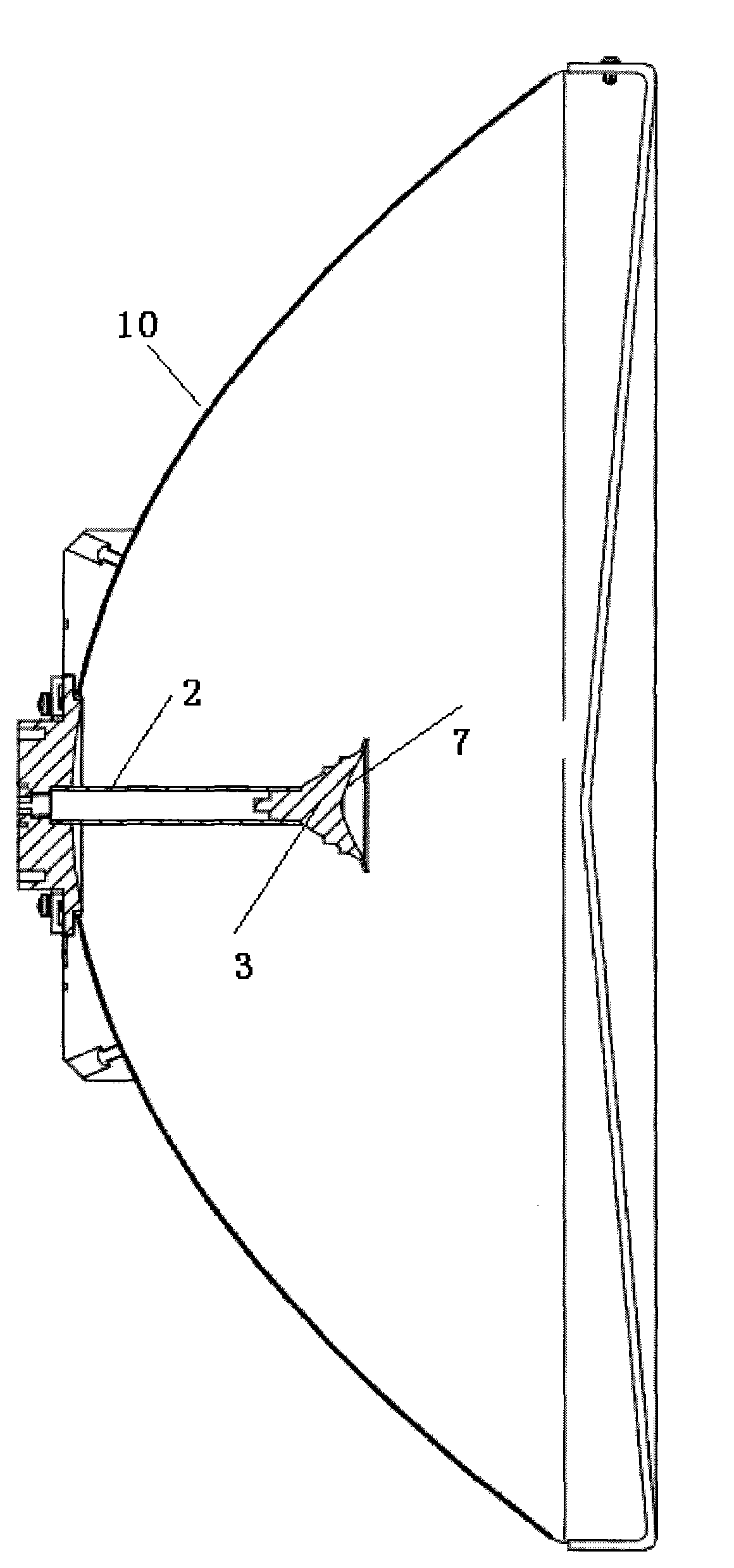

[0016] The preferred embodiment of the ultra-thin and ultra-high-performance microwave antenna of the present invention is as follows image 3 As shown, the microwave antenna is a double reflector antenna, and the antenna includes a main reflector 10, a secondary reflector 7, a metal feeding circular waveguide 2, a dielectric cone horn feed 3, and the like.

[0017] The main reflector 10 of this specific embodiment is a paraboloid, and its focal diameter ratio (F / D) can be about 0.19, is a "deep pot", and the secondary reflector 7 passes the dielectric cone horn feed 3 and the metal feed The circular waveguide 2 is closely connected, and the axes of the metal feeding circular waveguide 2 and the dielectric cone horn feed 3 and the main reflecting surface 10 can be on the same circular axis of symmetry.

[0018] The dielectric cone horn feed 3 in this specific embodiment can be made of polystyrene dielectric material.

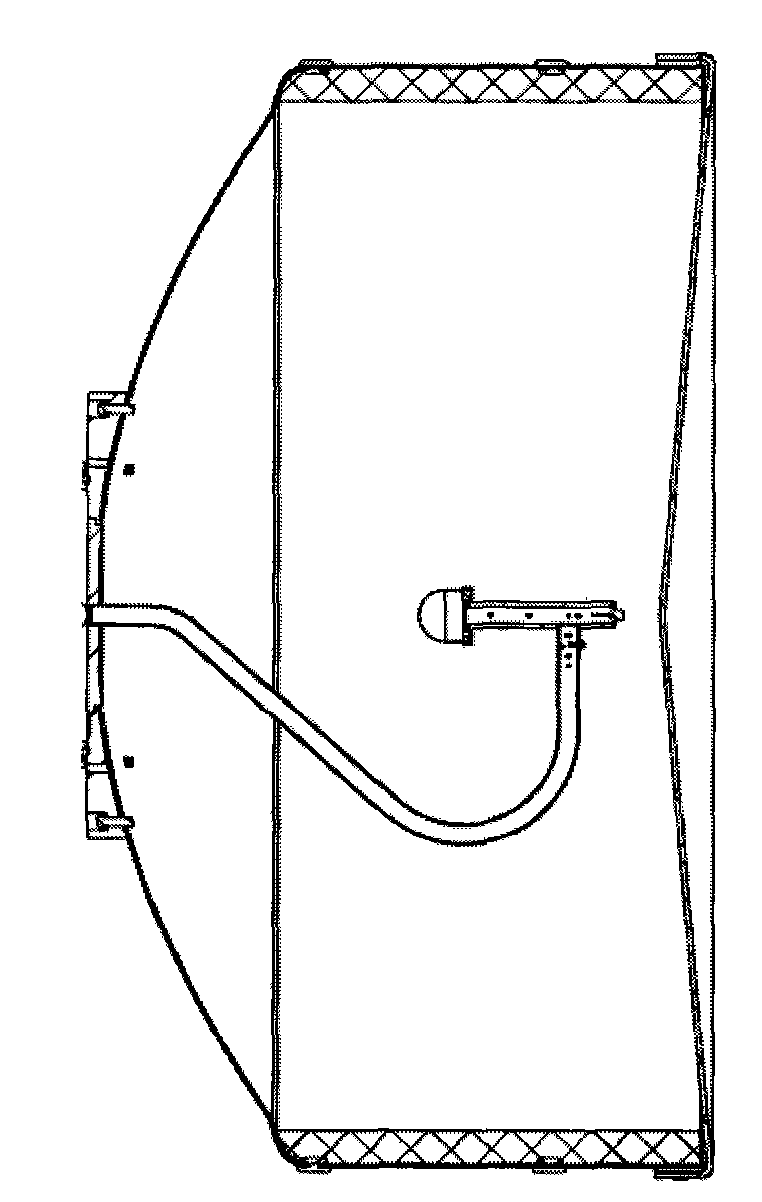

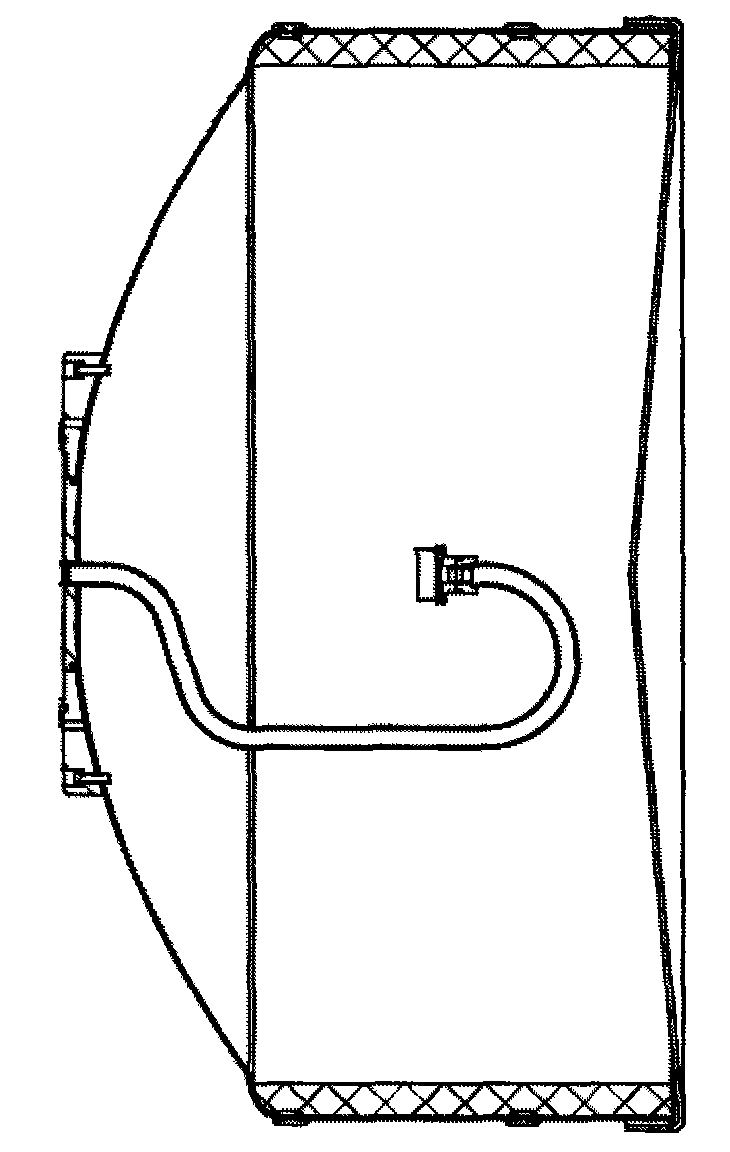

[0019] Such as Figure 4 , Figure 5 , Figure 6 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com