Passive thermal-sensitive fire extinguishing starter

A starter and passive heat technology, applied in fire rescue, etc., to achieve the effects of enhancing sensitivity, simplifying structure, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

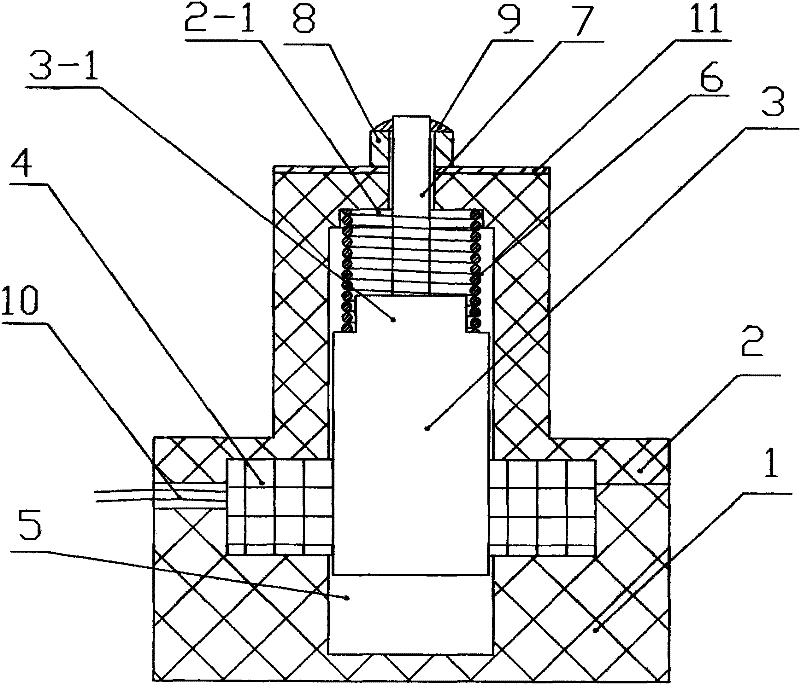

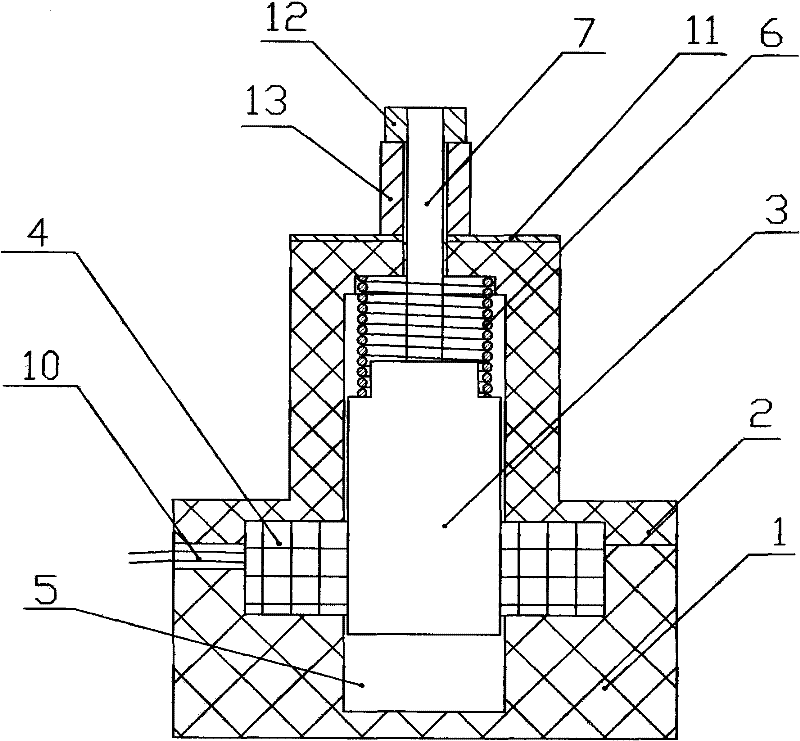

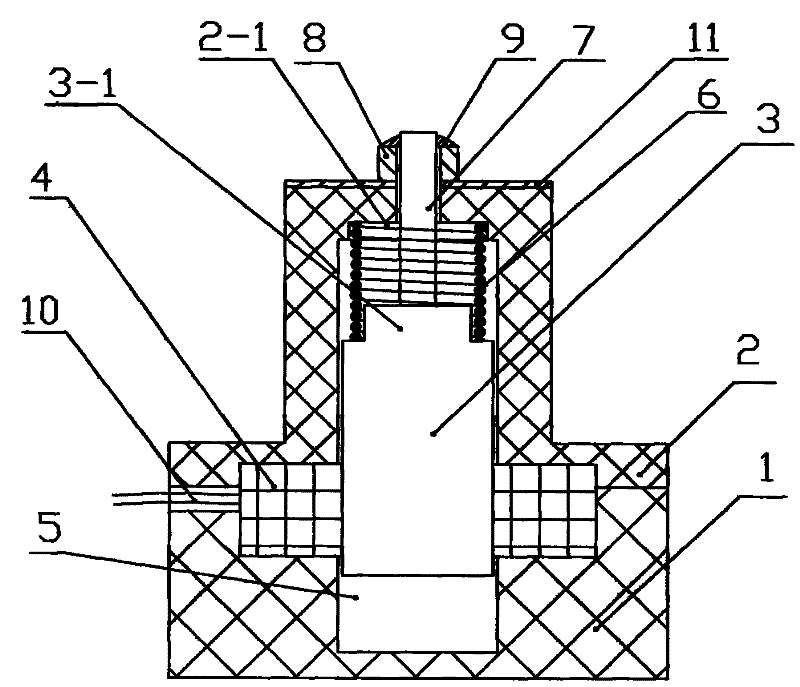

[0016] see figure 1 , it has a shell, the shell of this example is composed of a base 1 and an upper cover 2 fastened together, a magnetic power supply consisting of a magnetic bar 3 and an armature 4 is installed on the central axis of the shell, and the armature 4 sets On the magnetic rod 3, the armature 4 is fixed in the armature cavity formed by the fastening of the base 1 and the upper cover 2, so that it is fixed in the casing, and the magnetic rod 3 is arranged to move axially in the casing The stroke cavity 5 enables the magnet bar 3 to move axially; a spring 6 is installed at the tail of the magnet bar, and in order to enable the spring 6 to be installed stably, a reduced diameter is provided at the tail end of the magnet bar 3 The round platform 3-1 is provided with a circular groove 2-1 on the inner top wall of the upper cover, the lower end of the spring 6 is sleeved on the reduced-diameter round platform 3-1, and its upper end extends into the circular groove 2 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com