Method for rapidly disassembling radome on airplane and rotating locks

A radome and rotary lock technology, applied in aircraft parts, transportation and packaging, etc., can solve the problems of affecting the maintenance efficiency of the radar antenna, poor maintainability of the radar antenna, time-consuming disassembly and assembly of the radome, etc., to shorten the speed of opening and reliable. Installation time, meet the effect of fast opening and fast and reliable installation, improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

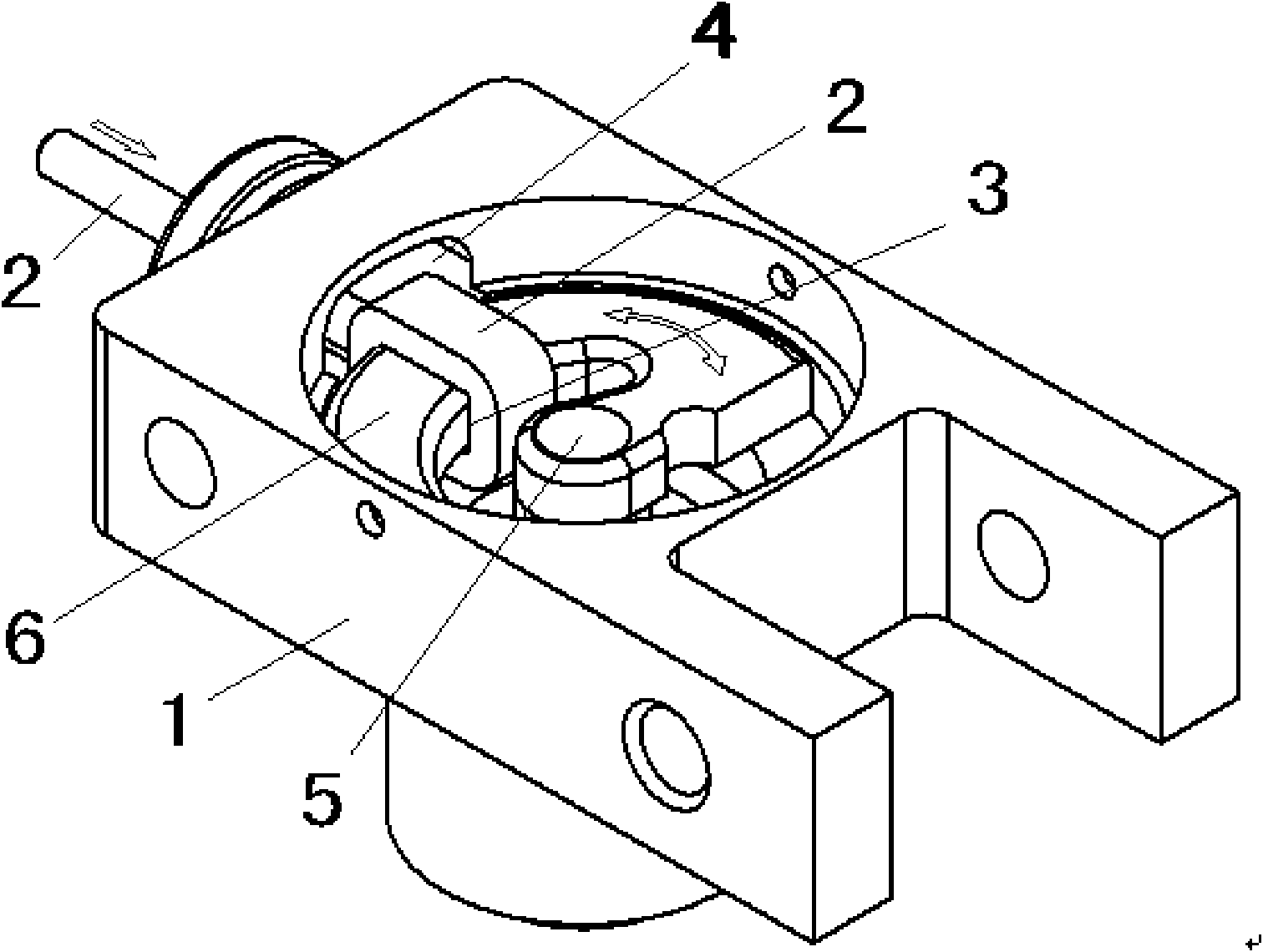

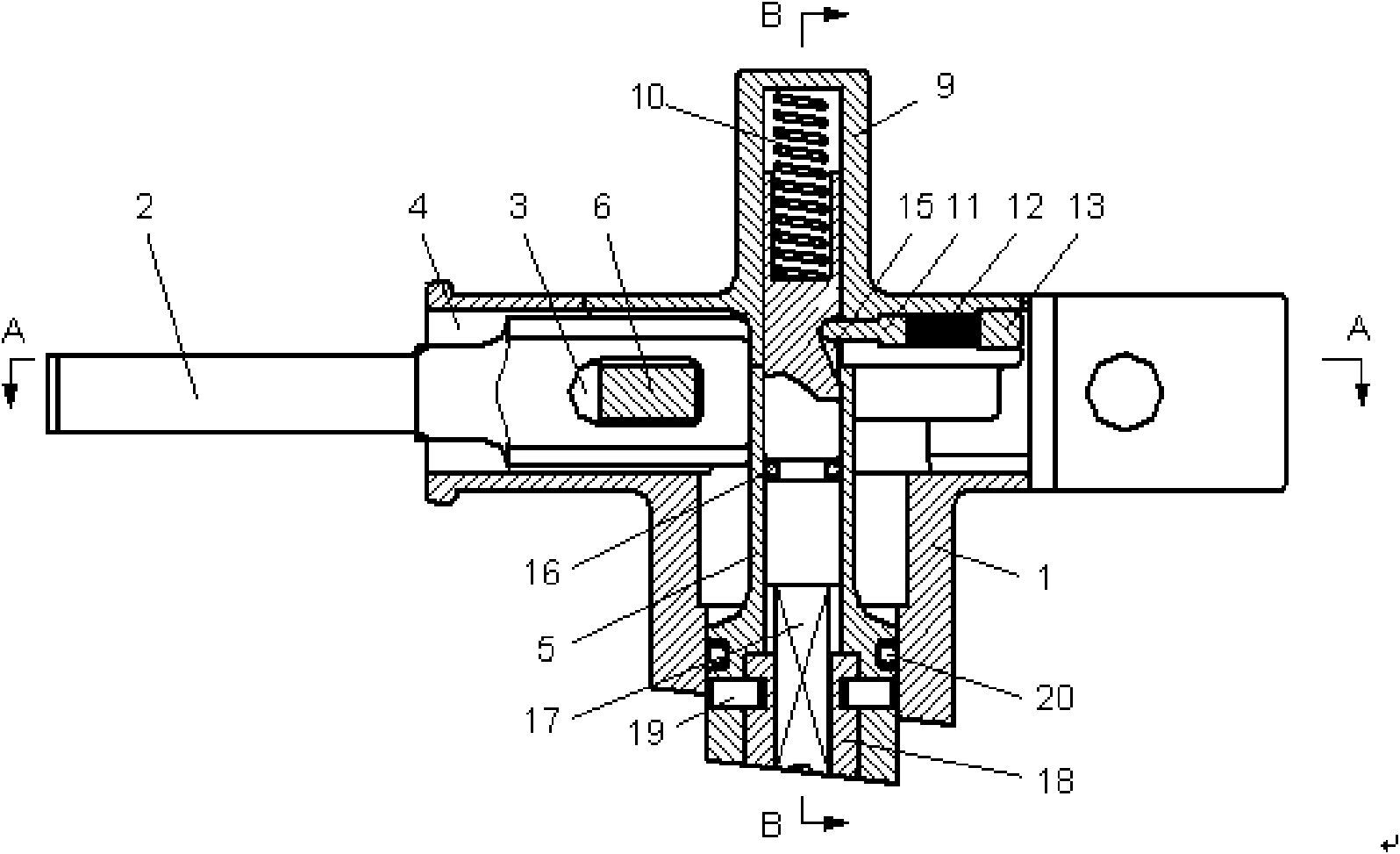

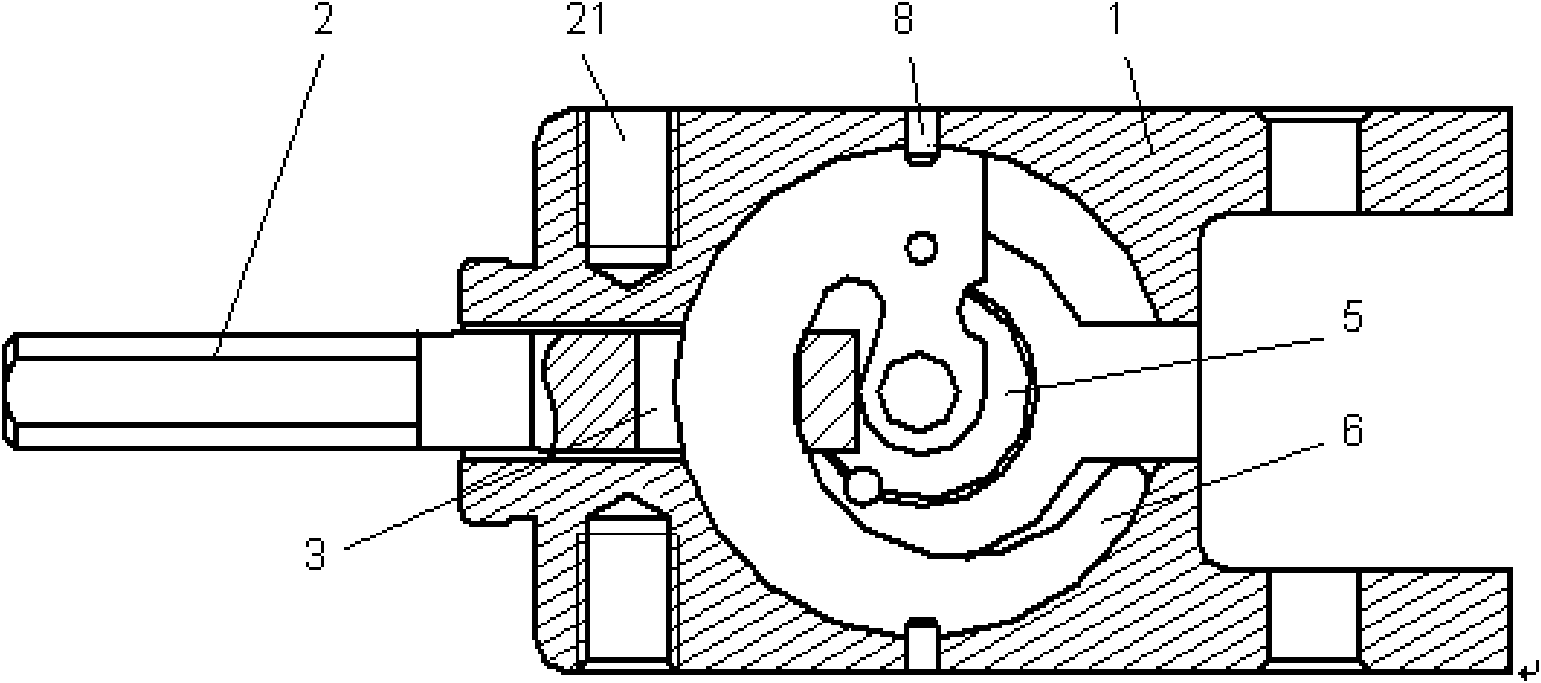

[0022] Embodiments of the present invention: when adopting the quick unloading method of the radome on a kind of aircraft of the present invention to implement, as figure 1 As shown, the method is to set a group of bolts 2 with holes on the edge of the radome, and set a group of rotary locks on the body frame corresponding to the bolts with holes 2; insert the bolts 2 with holes into the lock holes 4 of the rotary lock, and the rotary lock Core 5, make the snap close 6 on the lock core 5 penetrate in the hole bolt 3 bolt holes 3, the hole bolt 2 is hooked, so that the hole bolt 2 can not be pulled out.

[0023] When implementing the quick-release rotary lock of a radome on a kind of aircraft of the present invention, its principle is as follows: figure 1 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com