Lubricant anti-emulsifier composition and application thereof

A technology of anti-emulsifier and composition, which is applied in the direction of lubricating composition, petroleum industry, etc., and can solve the problems of influence, unfavorable anti-emulsification performance of oil products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

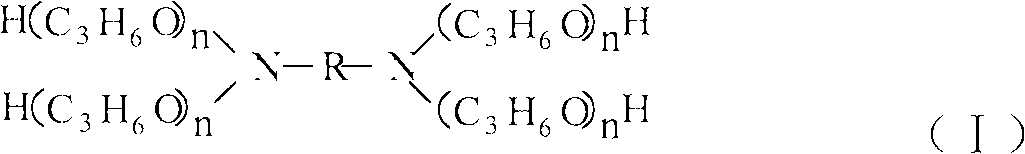

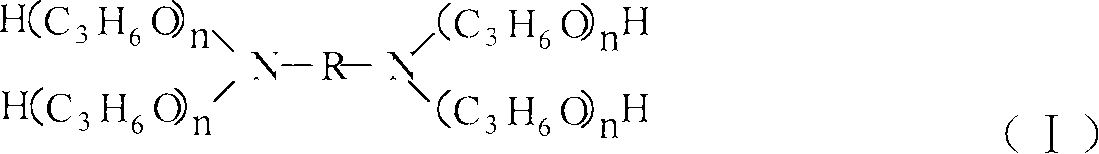

Method used

Image

Examples

Embodiment 1~6

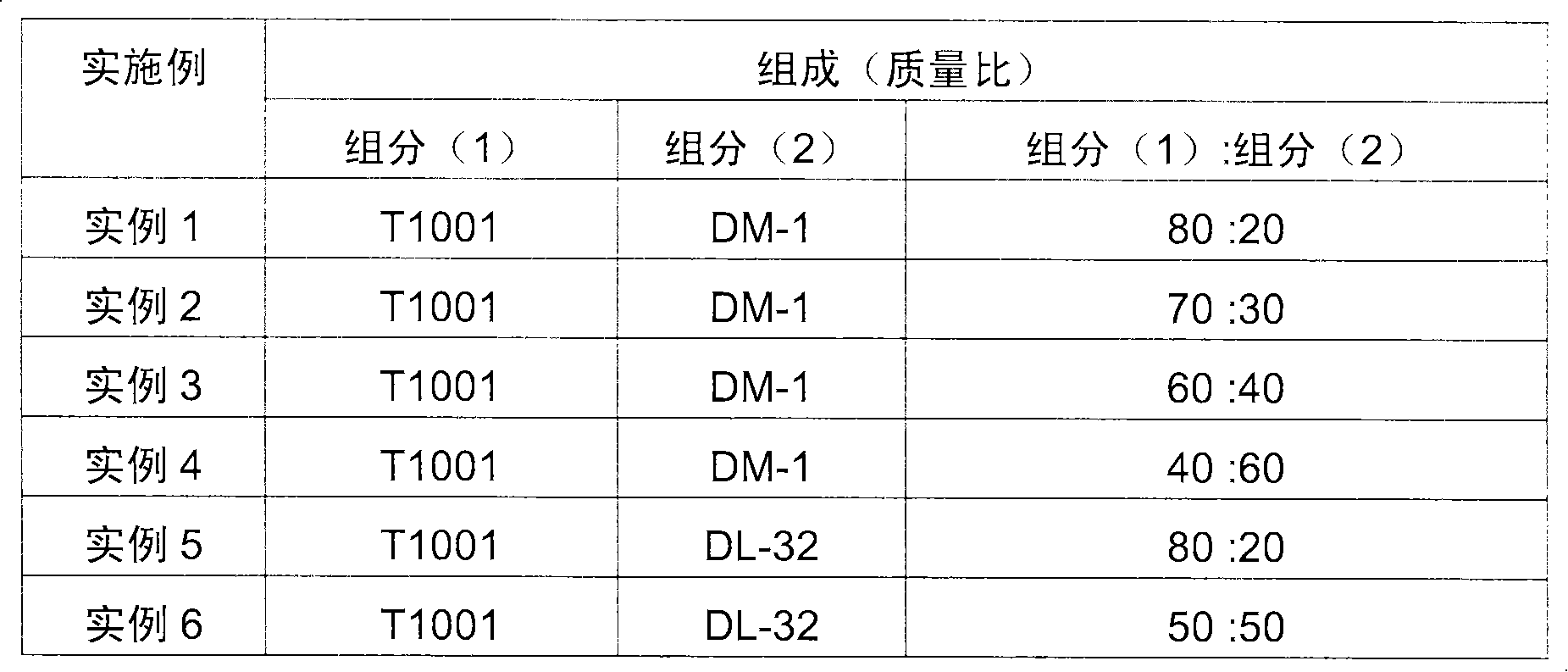

[0021] Examples 1-6 prepared the anti-emulsifier composition of the present invention and determined its main properties. Add alkylene diamine tetrapolyoxypropylene derivatives and ethylene oxide propylene oxide copolymers in different proportions into the mixing container, heat and stir under normal pressure, and adjust at 60±2°C for about 30 minutes to obtain the The product composition is shown in Table 1, and the physical and chemical properties are shown in Table 2. Among them, T1001 is an alkylene diamine tetrapolyoxypropylene derivative; DM-1 and DL-32 are ethylene oxide and propylene oxide copolymers produced by different manufacturers.

[0022] Table 1 Anti-emulsifier composition

[0023]

[0024] Table 2 Physical and chemical properties

[0025]

Embodiment 7

[0027] Use class I HVI150SN base oil with a viscosity of 35mm at 40°C 2 / s, add 0.5% steam turbine oil compounding agent, compounding agent contains antioxidant, antirust agent, extreme pressure antiwear agent, metal deactivator, is mixed with viscosity grade and is VG32 steam turbine oil, adds embodiment 1~6 preparation The anti-emulsifier composition of the present invention is evaluated using the GB / T7305 test method. The test temperature is 54 ° C, 40 mL of oil is mixed with 40 mL of water, and the emulsion layer is reduced to 3 mL (recorded as 40-37-3) mL and 0 mL (recorded as The time is 40-40-0) mL, expressed in minutes, the shorter the water separation time, the better the effect, the results are shown in Table 3.

[0028] table 3

[0029]

[0030] In the GB / T11120 standard of steam turbine oil, the technical requirement for demulsification performance is that the time for the oil to reach 40-37-3mL should not exceed 15 minutes. As can be seen from Table 3, the ti...

Embodiment 8

[0032] Use class II 300N hydrogenated base oil, its kinematic viscosity is 40°C, 48.92mm 2 / s, add 0.5% steam turbine oil compounding agent, compounding agent contains antioxidant, antirust agent, extreme pressure antiwear agent. It is formulated into a VG46 turbine oil with a viscosity grade, added the additive composition of the present invention prepared in Examples 1 to 6, and evaluated using the GB / T7305 test method. In this test, 40 mL of oil and 40 mL of water were stirred and mixed at 54 ° C, and the emulsified layer was reduced to The time of 3mL and 0mL is expressed in minutes, and the water is divided (the shorter the time, the better the effect, the results are shown in Table 4.

[0033] Table 4

[0034]

[0035] As can be seen from Table 4, when the hydrogenated turbine oil of higher viscosity grade does not contain a demulsifier, it cannot meet the oil product technical index requirements, and 0.01% (mass percentage) of Examples 1, 4, and 1 are added to the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com