Automatic control method for boiler oil burner and device thereof

An oil burner and burner technology, which is used in the control of combustion, lighting and heating equipment, etc., can solve the problems of not considering the operation of the equipment and not designing a self-starting and stopping control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the present invention easier to understand, the present invention will be further described below in conjunction with the drawings, but the embodiments in the drawings do not constitute any limitation to the present invention.

[0077] a. Explanation of Drawing Symbols

[0078] External input analog signal

[0079] External input analog signal

[0080] & - logical AND NOT - not logical

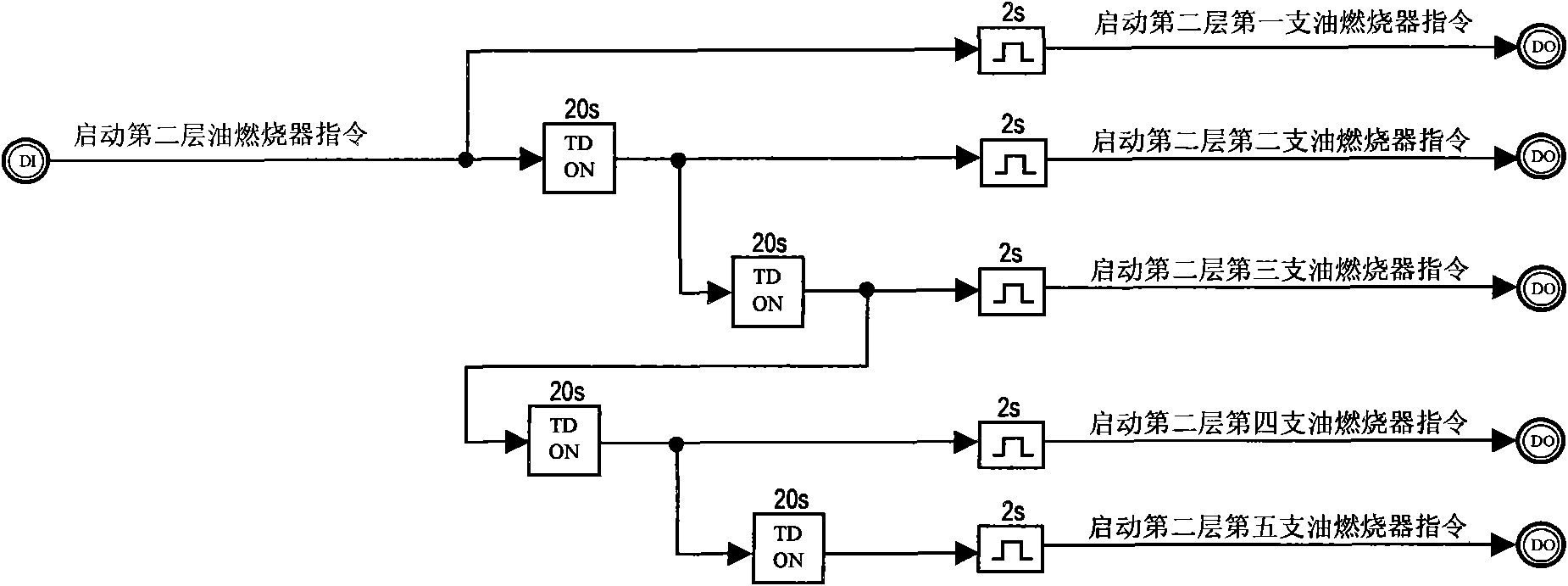

[0081] TD ON-delay pass OR-or logic

[0082] RS-RS flip-flop, R terminal first

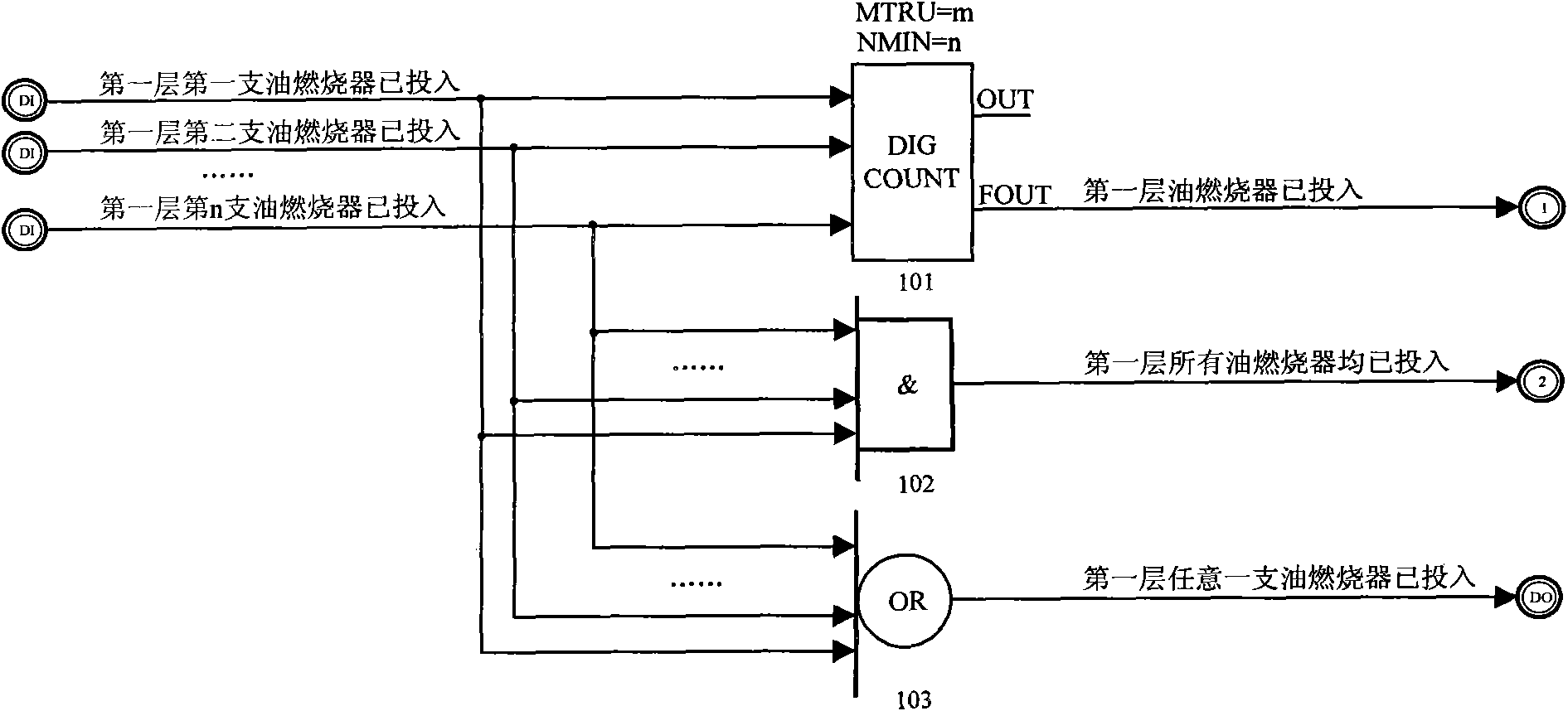

[0083] DIG COUNT - counting module, when the number of true in the n input ≥ m, the output FOUT is 1.

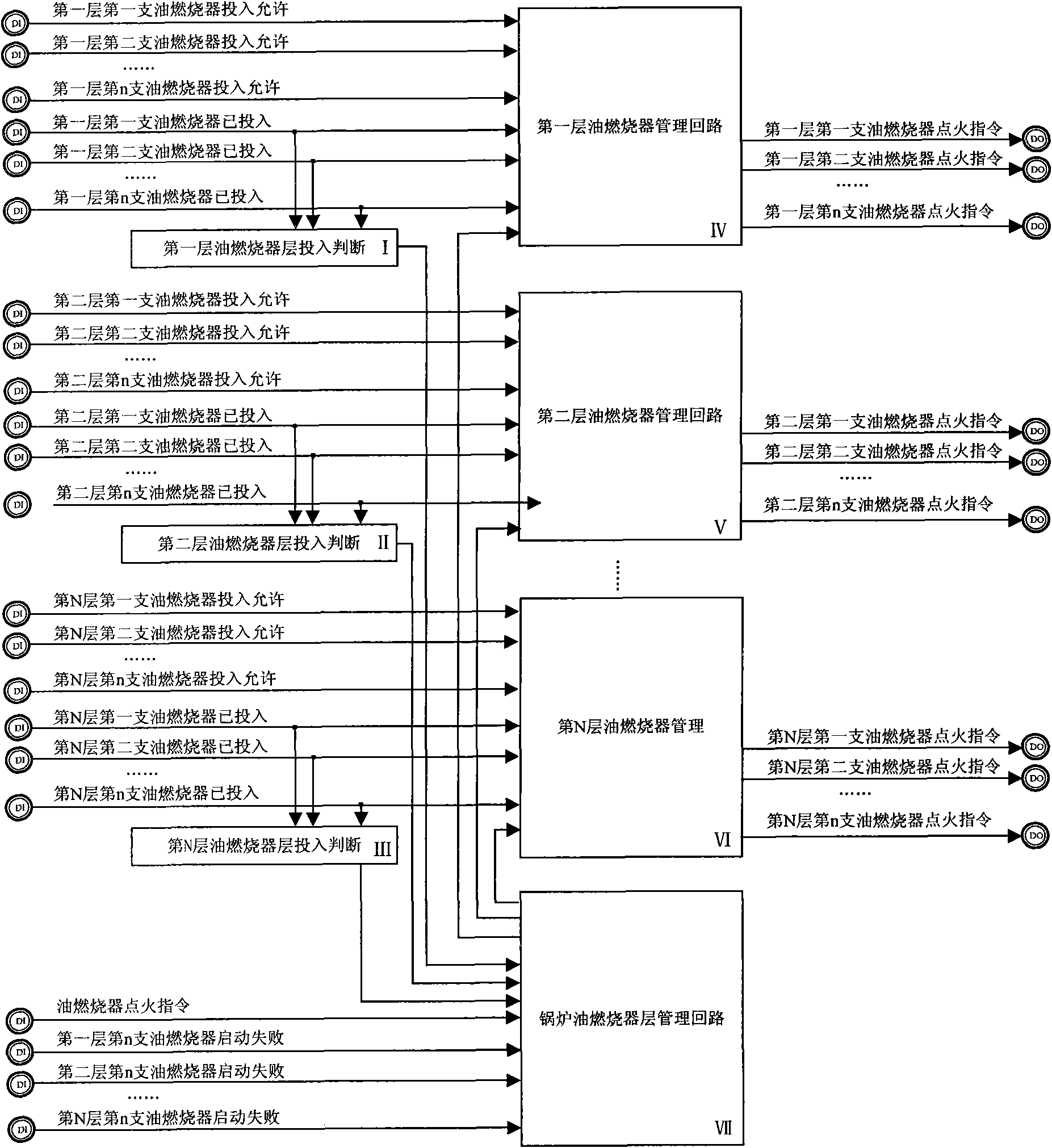

[0084] b. The management of the entire furnace oil burner,

[0085] The layout of the burners of the boiler is different, and the layer division of the oil burner is different. For the four-corner injection-fired boiler, the burners at the same horizontal height are defined as a layer; for the opposite burners arranged on the front and rear walls, the oil burner provides In term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com