Method for intelligently optimizing production scheduling of production process of flow industry enterprise

An intelligent optimization and production scheduling technology, applied in the field of automation, can solve problems such as slow calculation speed, inability to guarantee scheduling scheme, and complicated operation of scheduling method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical scheme and the accompanying drawings.

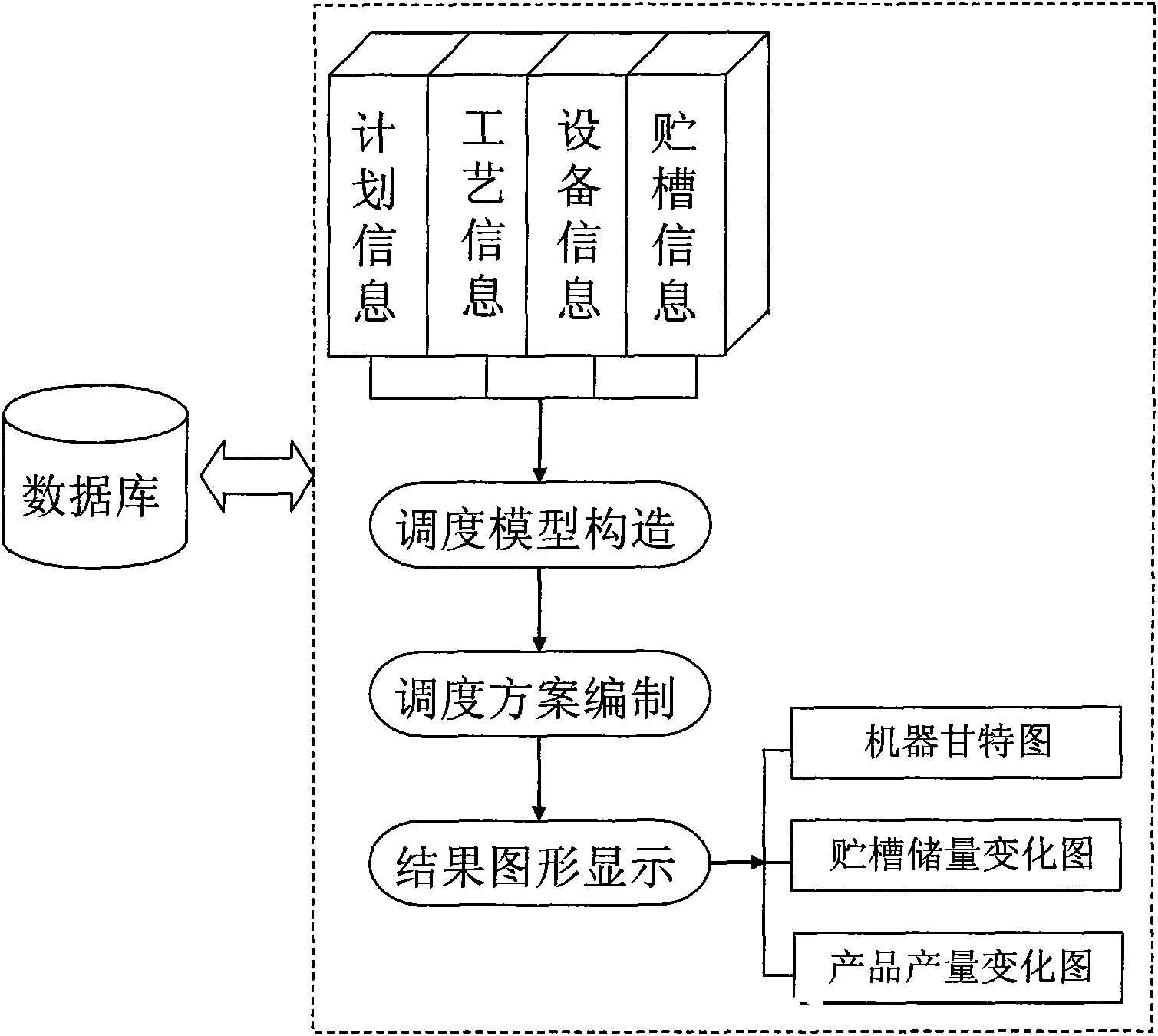

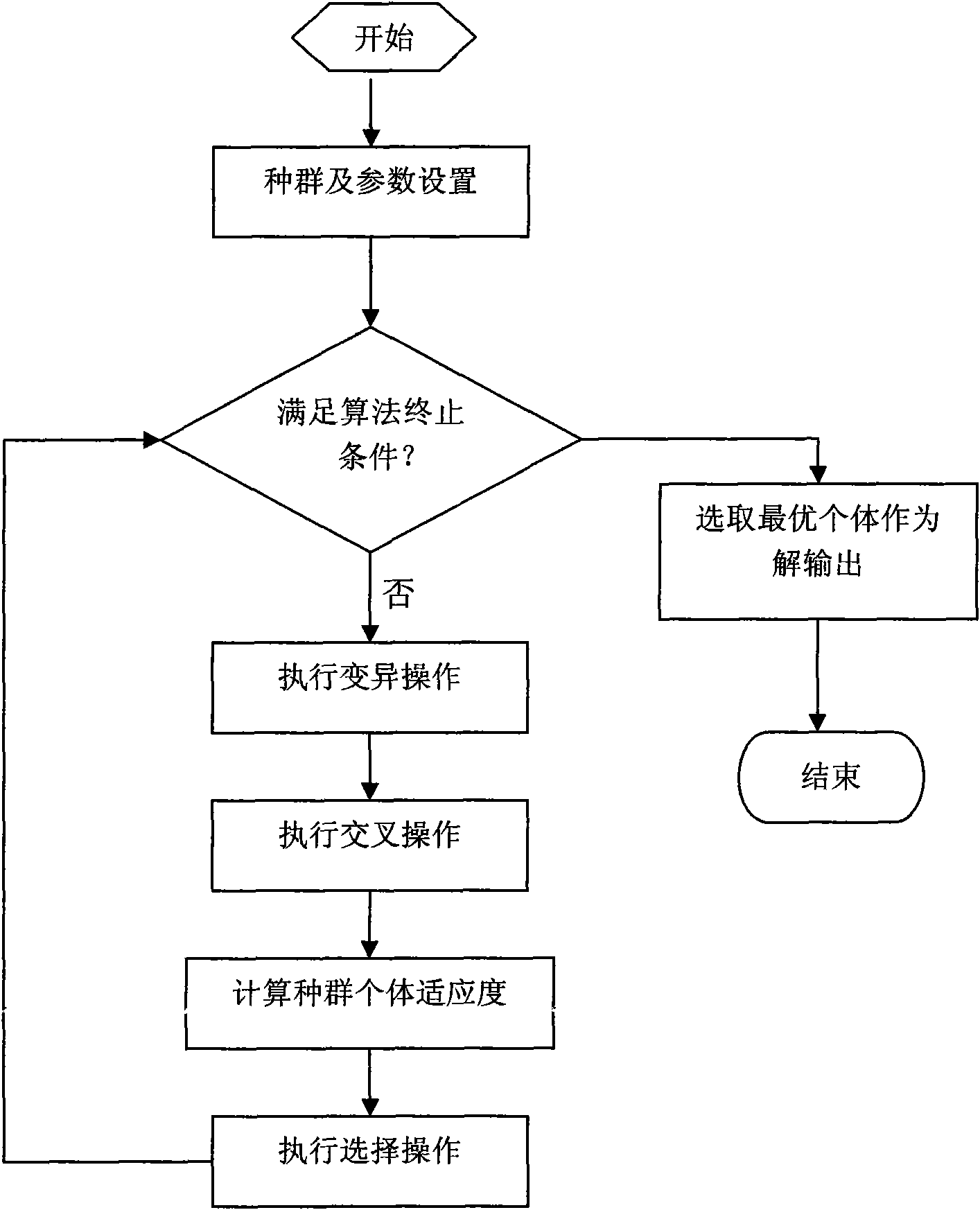

[0136] refer to Figure 1 ~ Figure 3 , an intelligent optimization method for production scheduling in the production process of a process industry enterprise. The scheduling determines the flow rate of each continuous production equipment in each time period and the processing capacity (batch) of each intermittent production equipment in each time period on the production line, so that target optimization. Composition block diagram such as figure 1 As shown, it consists of three parts: model construction, scheduling scheme compilation, and database system. The scheduling scheme compilation part adopts the differential evolution algorithm as the solution algorithm of the model.

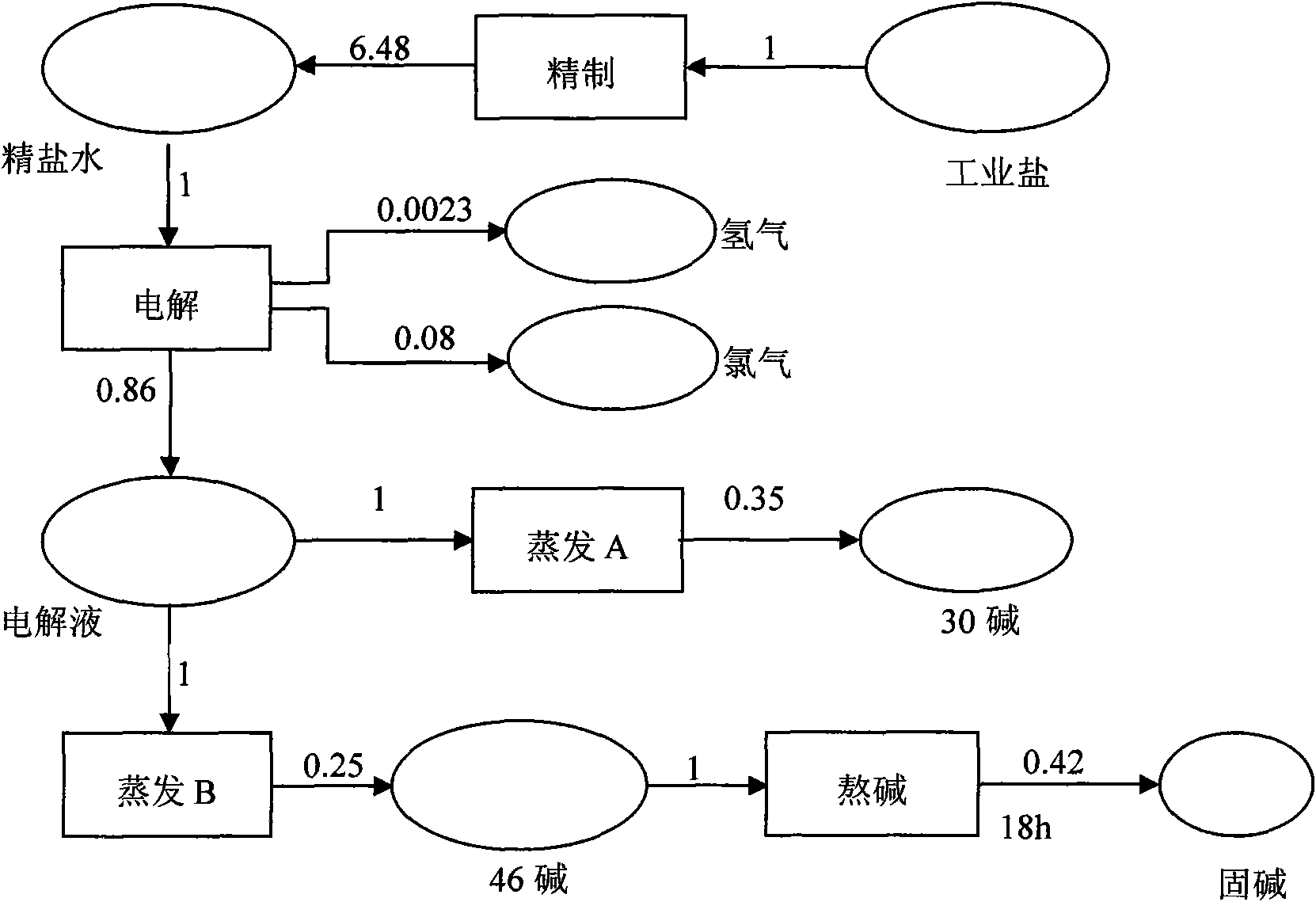

[0137] 1) Scheduling model establishment

[0138] In order to facilitate modeling and algorithm solution, the scheduling ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com