Preparation method of alloy thin strip magnet of Sm(Co,Cu,Fe,Zr)-z type

A technology of thin strips and magnets, which is applied in the manufacture of magnets, magnetic objects, inductors/transformers/magnets, etc., and can solve the problems that thin strip magnets cannot be produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

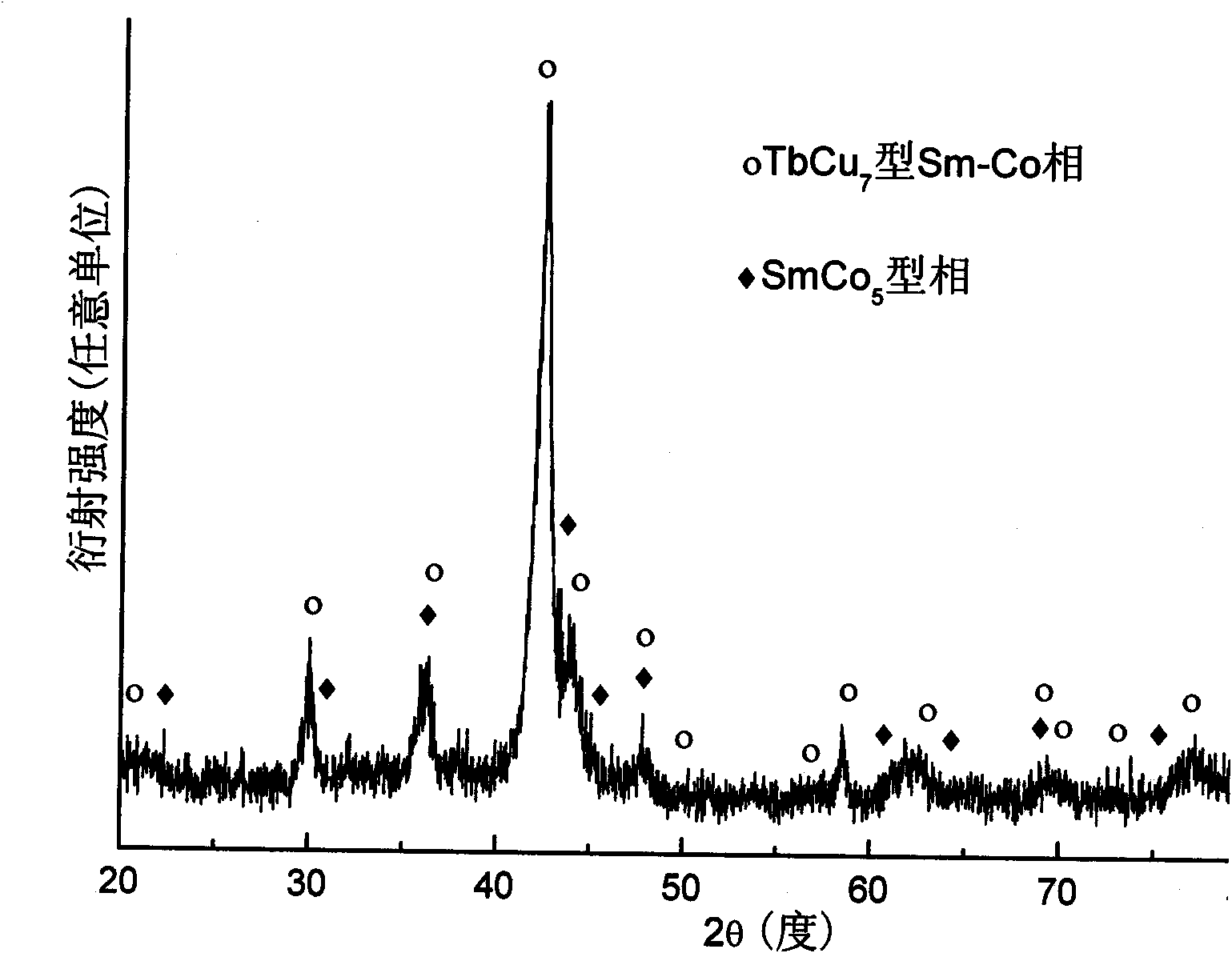

Embodiment 1

[0037] The first step, raw material preparation

[0038] According to the atomic percentage ratio of raw materials Sm (Co 0.678 Cu 0.067 Fe 0.222 Zr 0.033 ) 7.5 , Weigh the component raw materials pure Sm, Co, Cu, Fe and Zr, add 2% pure Sm according to the mass percentage of the pure Sm weighed by the raw material ratio when batching, thus complete the raw material preparation.

[0039] The second step is to melt the raw materials to prepare master alloy ingots

[0040] Put all the raw materials prepared in the first step into the crucible of the vacuum induction melting furnace, and evacuate the furnace body to a degree of vacuum of less than 10 -2 Pa, the furnace temperature rises to higher than the highest melting point of the raw material metal until all the raw material metal is smelted evenly, and the evenly smelted Sm(Co 0.678 Cu 0.067 Fe 0.222 Zr 0.033 ) 7.5 melt, and then the melt was cooled in a water-cooled copper crucible to obtain cast Sm(Co 0.678 Cu 0...

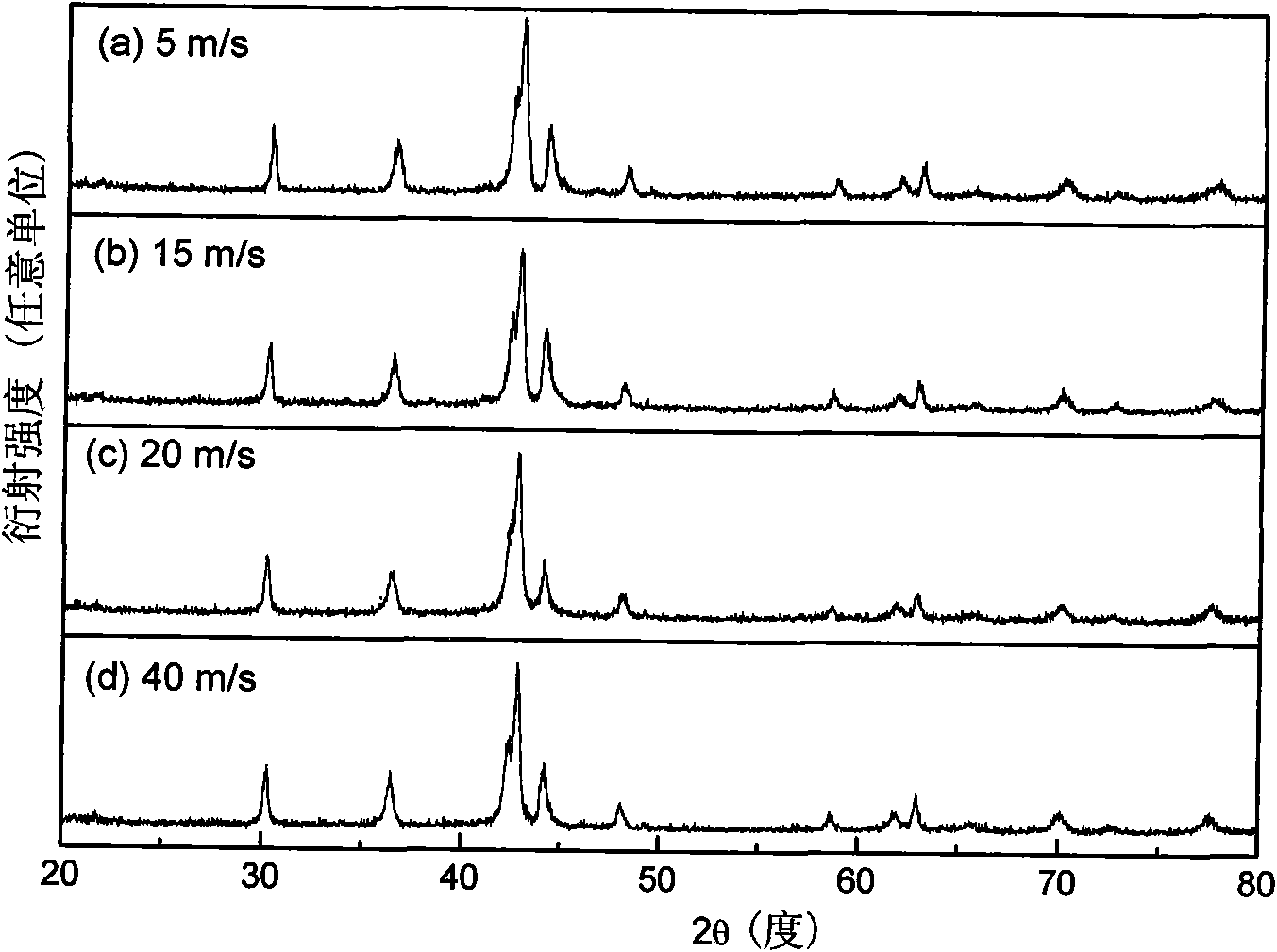

Embodiment 2

[0050] Except changing the raw material ratio of the first step in embodiment 1 into Sm(Co 0.685 Cu 0.062 Fe 0.247 Zr 0.028 ) 7.5 , the circumferential speed of the cooling molybdenum roll of the third step, that is, the quenching speed of the melt becomes 5m / s, and the others are all the same as in Example 1.

Embodiment 3

[0052] Except changing the raw material ratio of the first step in embodiment 1 into Sm(Co 0.703 Cu 0.068 Fe 0.199 Zr 0.030 ) 7.5 , the circumferential speed of the cooling molybdenum roll of the third step, that is, the rapid quenching speed of the melt becomes 15m / s, and the others are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com