Epoxy-pouring full-insulation solid isolating switch

A technology of epoxy casting and isolating switches, which is applied in the direction of switches with movable electrical contacts, etc., can solve the problems of limited use places, poor operation stability, and large space in the isolation room, and achieve improved dynamic and thermal stability. , Stable and reliable performance, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

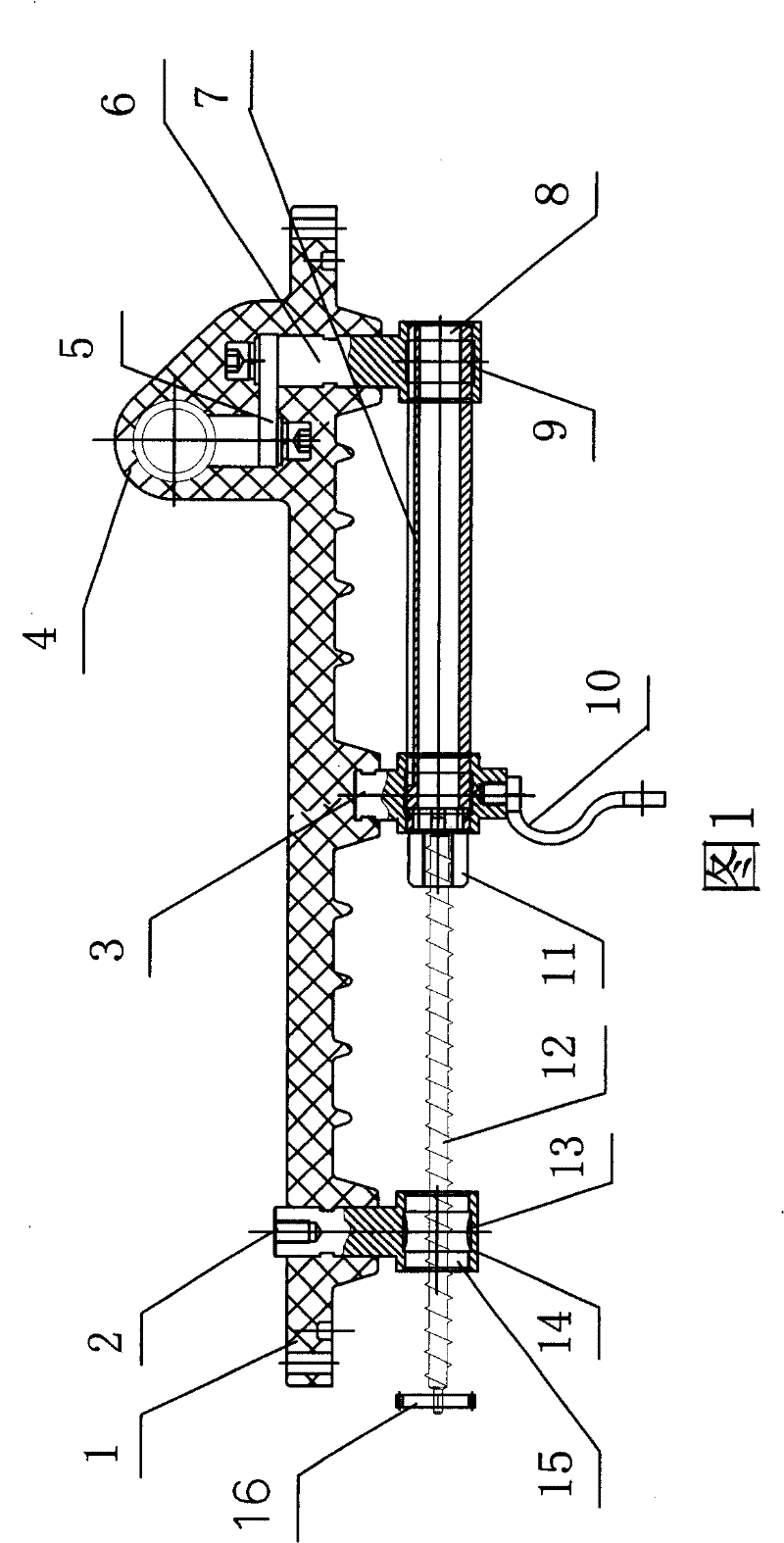

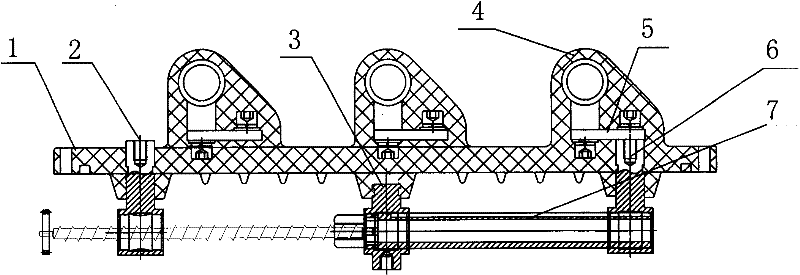

[0036] Epoxy cast solid fully insulated isolating switch, including isolating body 1, grounding contact 2, isolating contact 6, intermediate contact 3 and isolating moving contact 7;

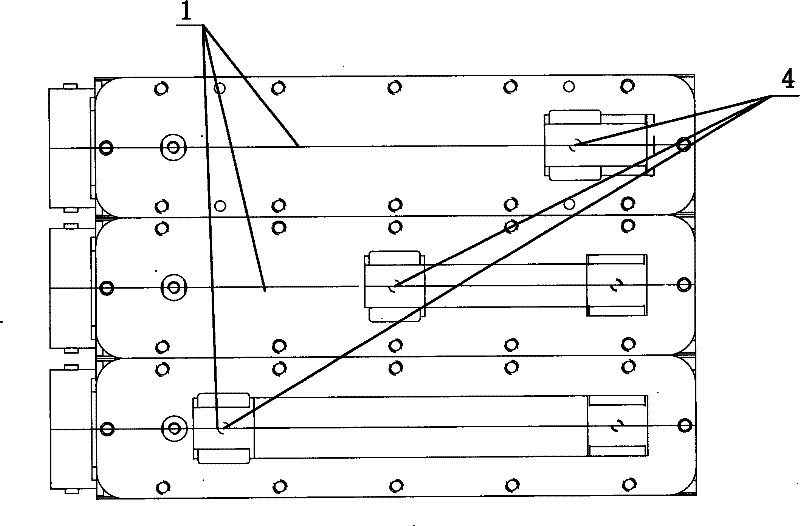

[0037] The two ends of the isolation body 1 are respectively fixed with a ground contact 2 and an isolation contact 6, and an intermediate contact 3 is fixedly installed in the middle part of the isolation body 1. The top of the isolation body 1 is provided with a busbar contact 4. The busbar The contacts 4 are fixedly connected to the isolating contacts 6 through the busbars 5 . The isolation contact 6, the lower part of the middle contact 3 and the ground contact 2 are provided with a contact base 9 with the same structure. The three contact bases 9 are located on the same horizontal line. The middle part of the hole 15 is provided with a bracelet contact finger groove 14 , and the bracelet contact finger groove 14 is inlaid with a commercially available standard bracelet contact finger 13 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com