Material position detecting method and device based on vibration signal of ball grinder rotating cylinder body

A material level detection and vibration signal technology, which is applied in the field of material level detection method and detection device based on the vibration signal of the rotating cylinder of a ball mill, can solve the problems of material level relying on manual operation, limited measurement accuracy, and material level measurement deviation. Achieve the effect of improving operation economy and reliability, accurate and reliable measurement data, and small material level measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A material level detection method based on the vibration signal of a ball mill rotating cylinder, the method comprises the following steps:

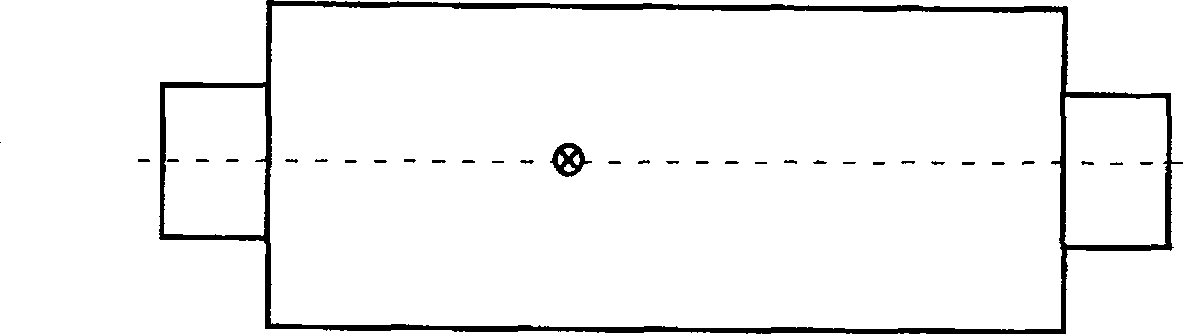

[0037] A) A vibration acceleration sensor is installed on the ball mill drum, in this embodiment, the vibration acceleration sensor is located in the middle of the ball mill drum,

[0038] B) Determine the sampling parameters of sensor data collection, which include the sampling frequency and the number of sampling points, and calculate the circumferential angle L through which the sensor collects a set of data measuring points according to the sampling frequency and the number of sampling points,

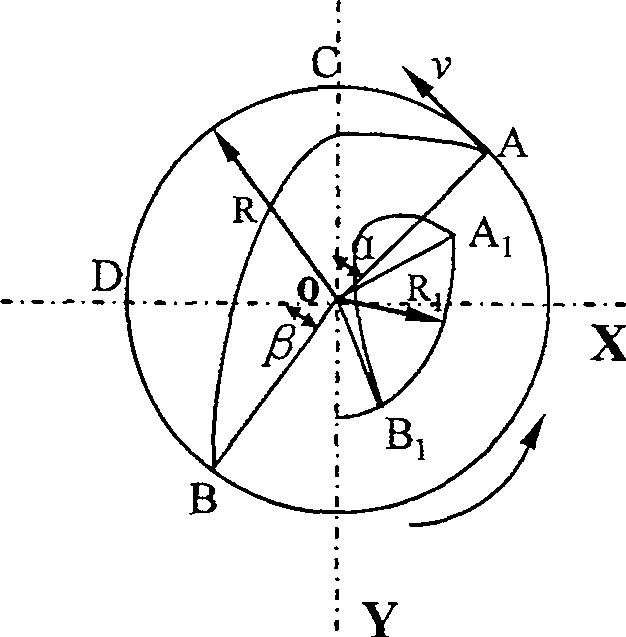

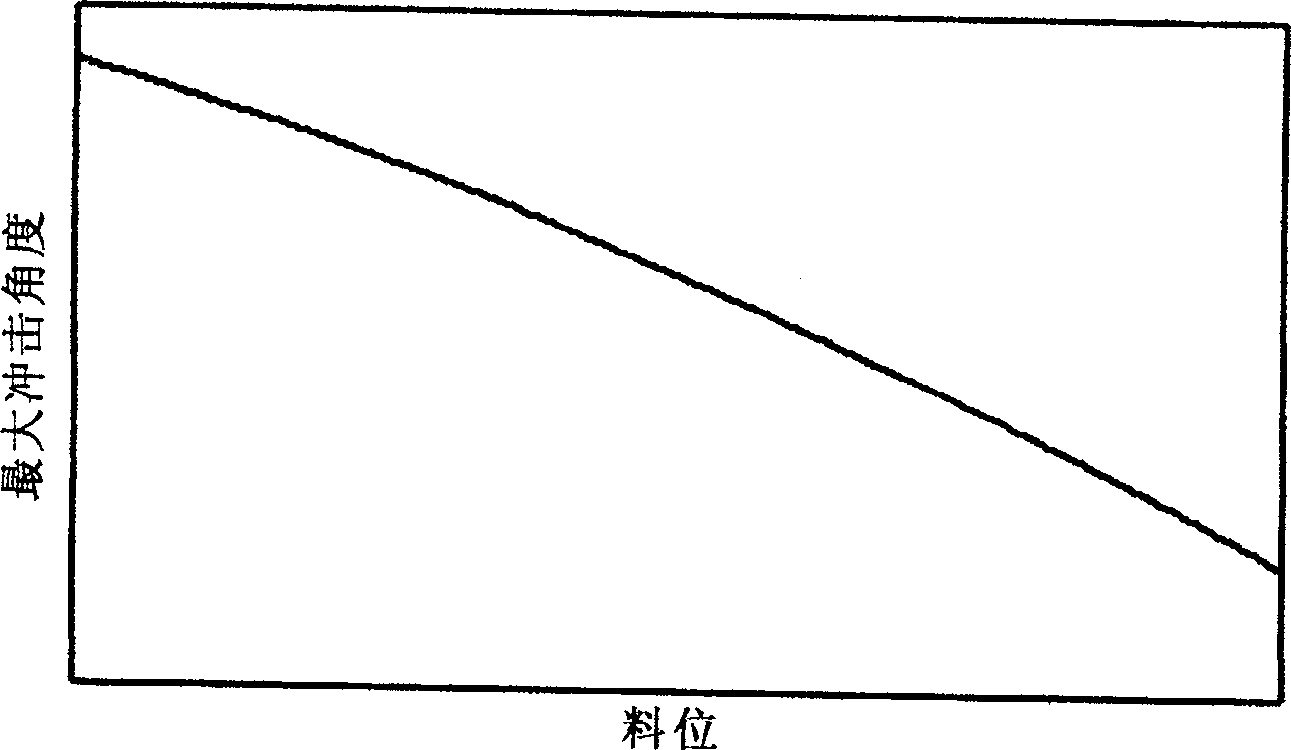

[0039] C) Determine the circumferential area of data collection by the sensor on the cylinder: first calculate the theoretical maximum impact point of the steel ball in the drum of the ball mill, pass the material level calibration experiment, and use the theoretically calculated maximum impact point of the steel ball as the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com