An air-feather airflow directional load transport aircraft

A technology of aircraft and wings, which is applied in the field of air-feather airflow directional load transport aircraft, can solve problems such as the complexity of the transmission system, and achieve the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

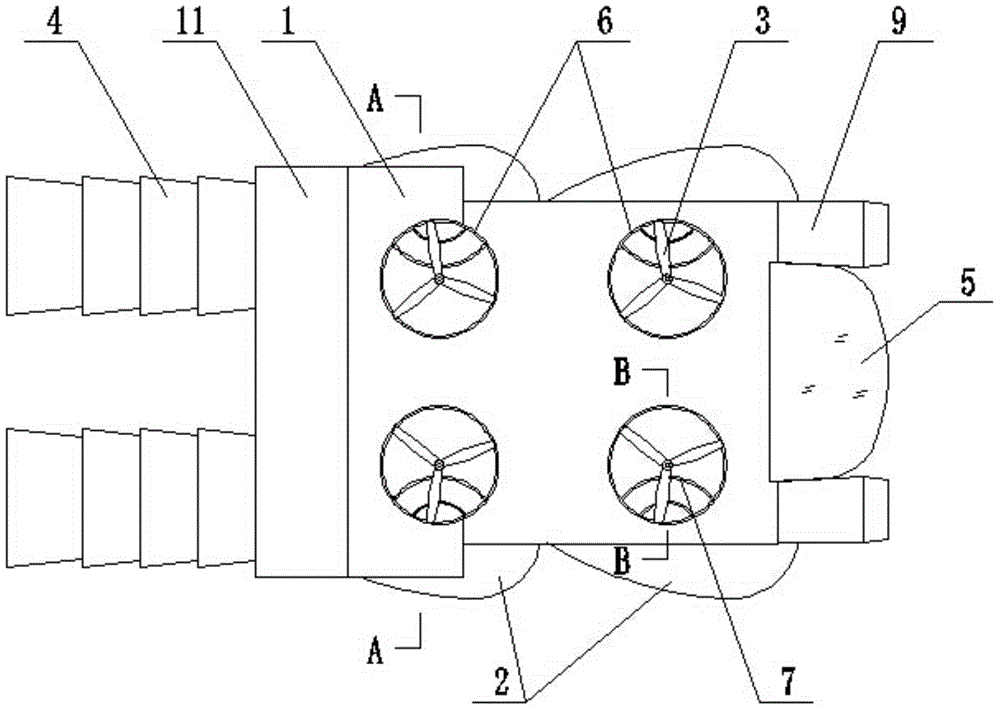

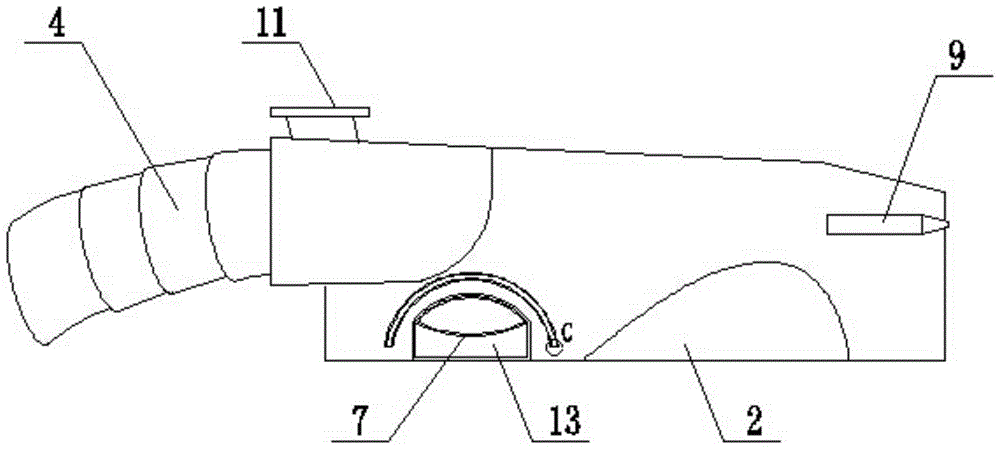

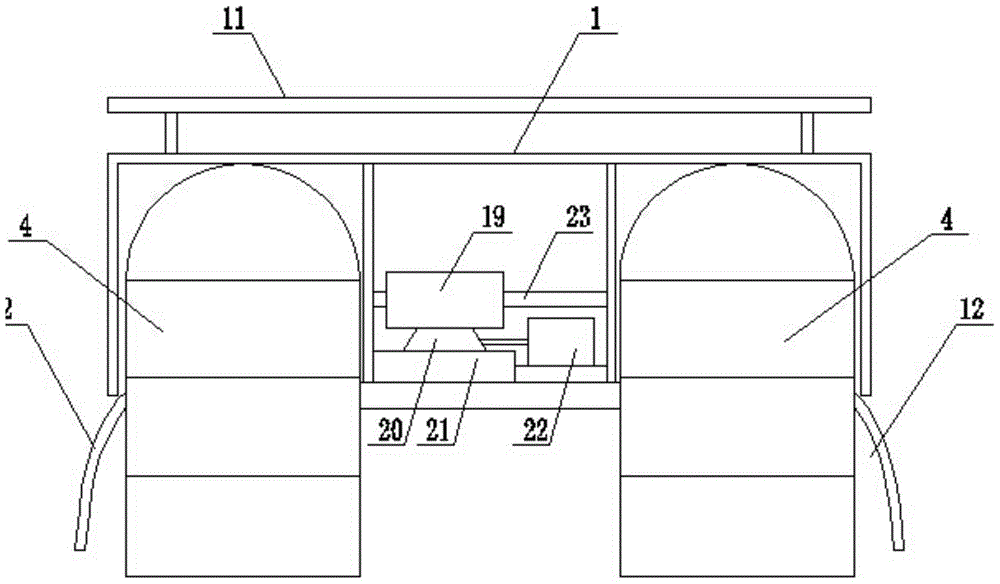

[0034] refer to Figure 1 to Figure 5, the air-feather airflow directional load transport aircraft includes a body 1, a control room 5, a lift system and a propulsion system, the lift system includes 4 wings 2, 4 lift ducts 6 and 4 propellers 3, the The control room 5 is located at the front of the body 1, and is equipped with a central control system, a power transmission system, various monitoring instruments and a satellite positioning system, etc., and the middle part of the body 1 is provided with two lifting ducts 6 near the left and right sides. , each lifting duct 6 is provided with a propeller 3, the propeller 3 is a coaxial counter-rotating propeller, its drive shaft is connected with the piston engine or turbine engine in the control room 5, and the sides on both sides of the body 1 The wall is provided with an air jet window 13 next to each lift duct 6, the upper half of the lift duct 6 is vertical, and the lower half is curved to the jet window 13 and communicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com