Method for cleaning wafer and cleaning device

A technology for cleaning devices and wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of waste wafers, adverse effects of wafers, etc., to facilitate control and avoid solvents mixed, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

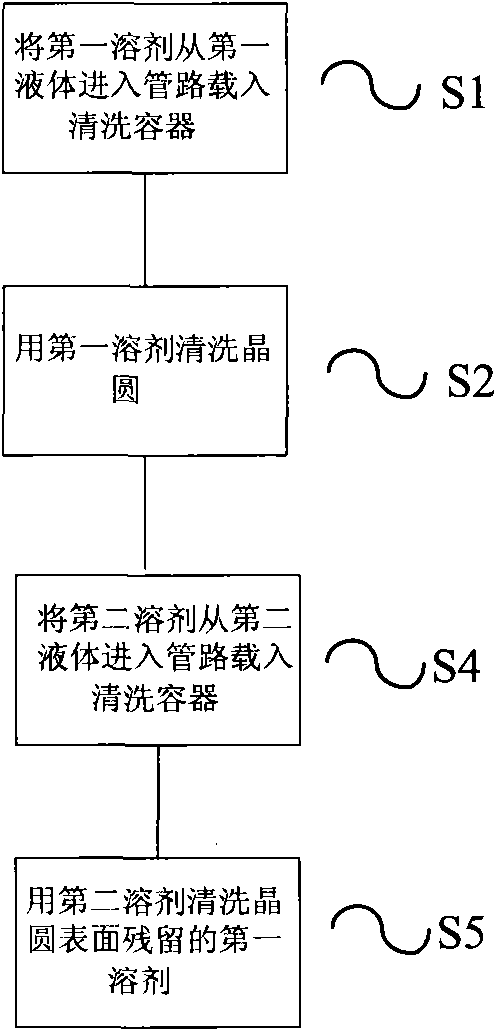

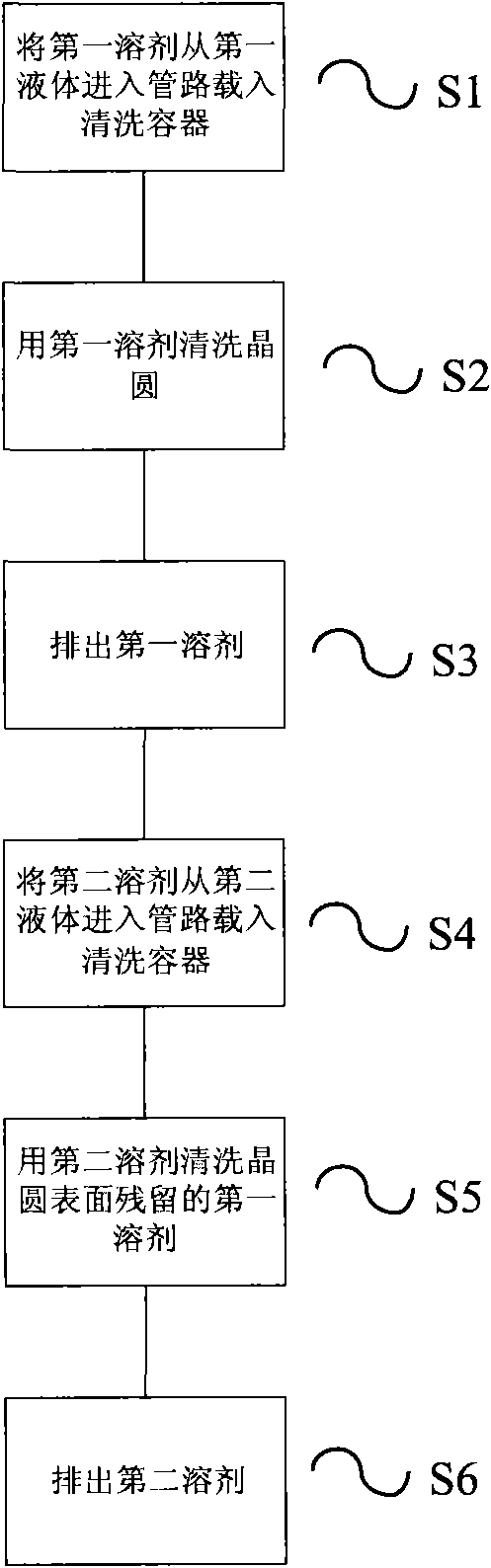

[0042] Such as figure 1As shown, the method includes step S1, inputting the first solvent from the first liquid into the pipeline into the cleaning container, step S2 using the first solvent to clean the wafer, and step S4, inputting the second solvent from the second liquid into the pipeline for cleaning In the container, step S5 uses the second solvent to clean the first solvent on the surface of the wafer. When a failure occurs and the wafer cannot be taken out from the cleaning container, use the second solvent to clean the first solvent on the surface of the wafer to avoid corrosive effects on the wafer. The solvent corrodes the wafer and produces wafer waste, which improves the economy of the wafer cleaning process.

[0043] In order to completely remove the first solvent from the wafer surface, a preferred solution is that the second solvent can dissolve the first solvent. In this way, after the second solvent is input into the cleaning container, the container is sti...

Embodiment 2

[0051] This embodiment provides a cleaning device using the wafer cleaning method in Embodiment 1.

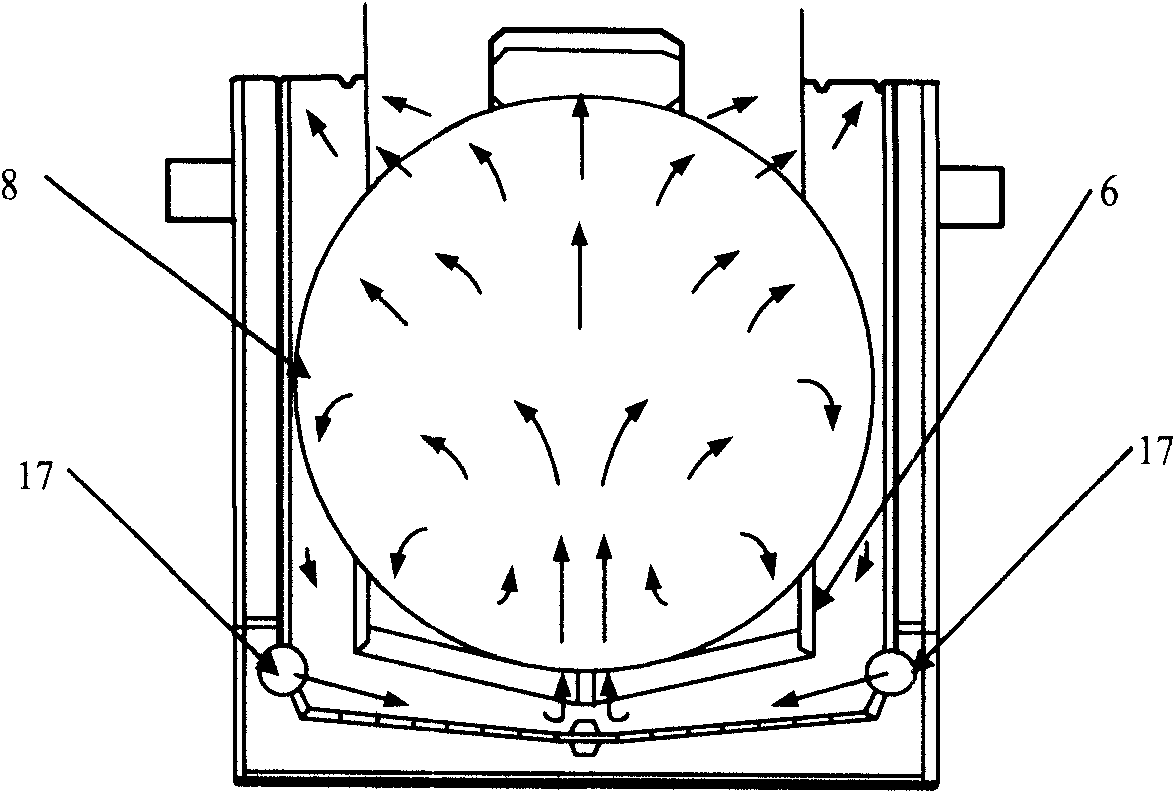

[0052] Such as Figure 4 As shown, this embodiment provides a wafer cleaning device. The cleaning container 7 is provided with a first liquid inlet pipeline 1 for introducing a first solvent, and a second liquid inlet pipeline 2 for introducing a second solvent. By assembling the second liquid into the pipeline 2, providing the passage for the second solvent to enter the cleaning container, the first solvent that remains on the surface of the wafer 8 from the first liquid into the pipeline 1 can be eluted, thereby avoiding the long-term use of the first solvent. The wafer is corroded by contact with the wafer for a long time, thereby improving the economy of the wafer cleaning process and the process adaptability under abnormal working conditions.

[0053] More specifically, the cleaning device includes a cleaning container 7 whose main body is hollow. In the normal use state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com