Novel blowing device of cold rolling device

A new type of equipment technology, used in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of high noise, difficult maintenance and high cost of purging devices, reduce energy consumption and cost, and improve working environment. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

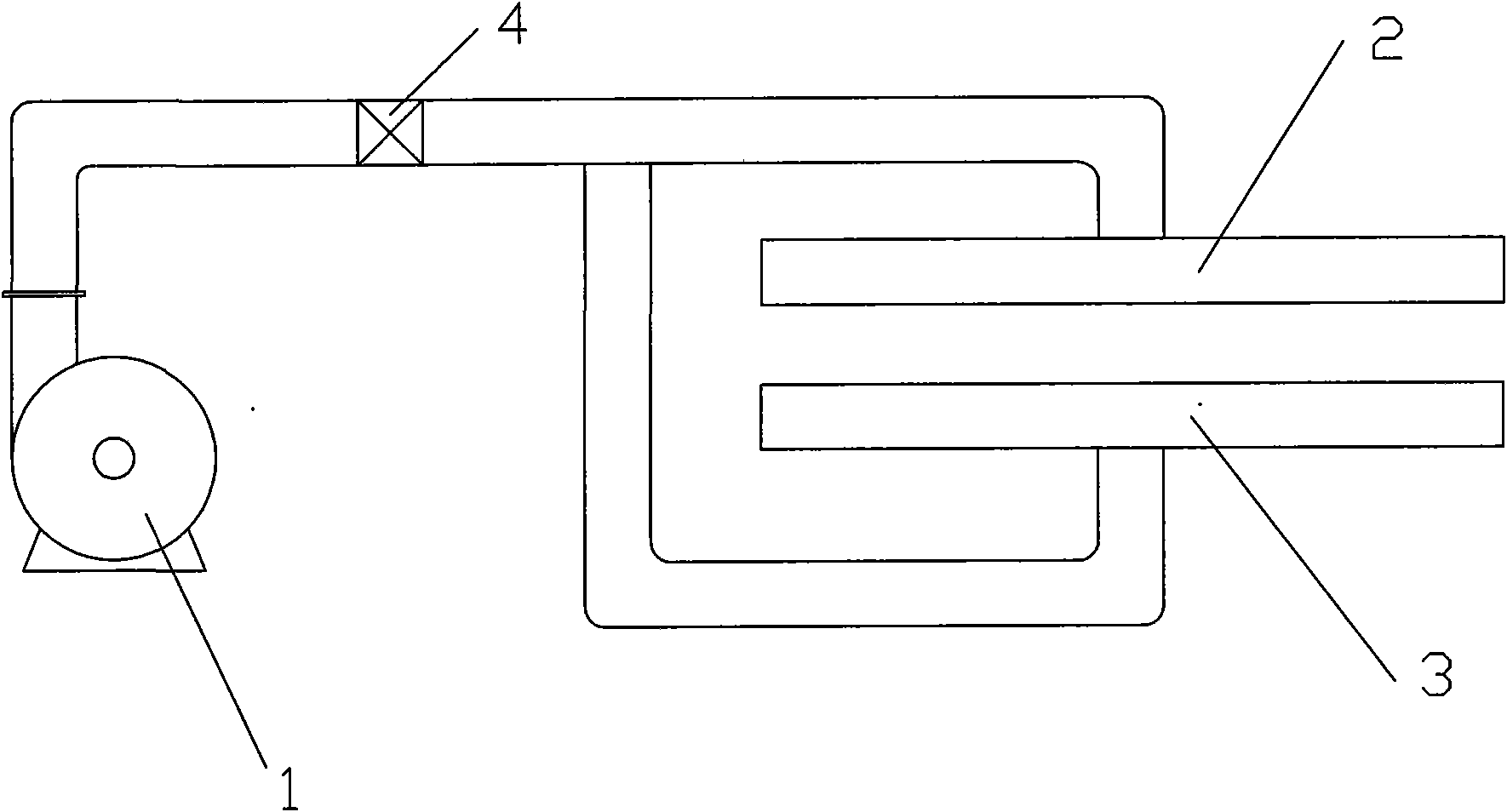

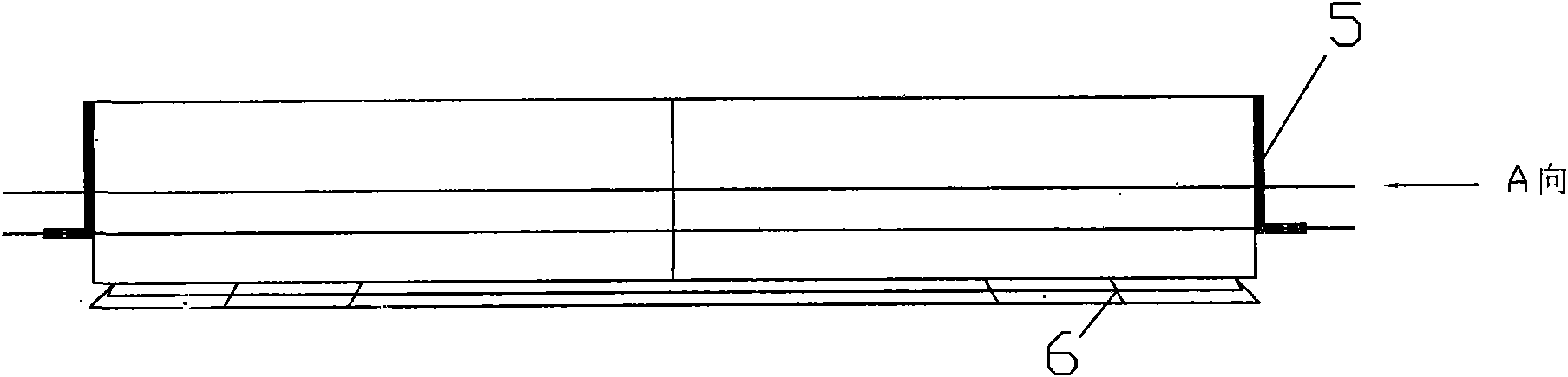

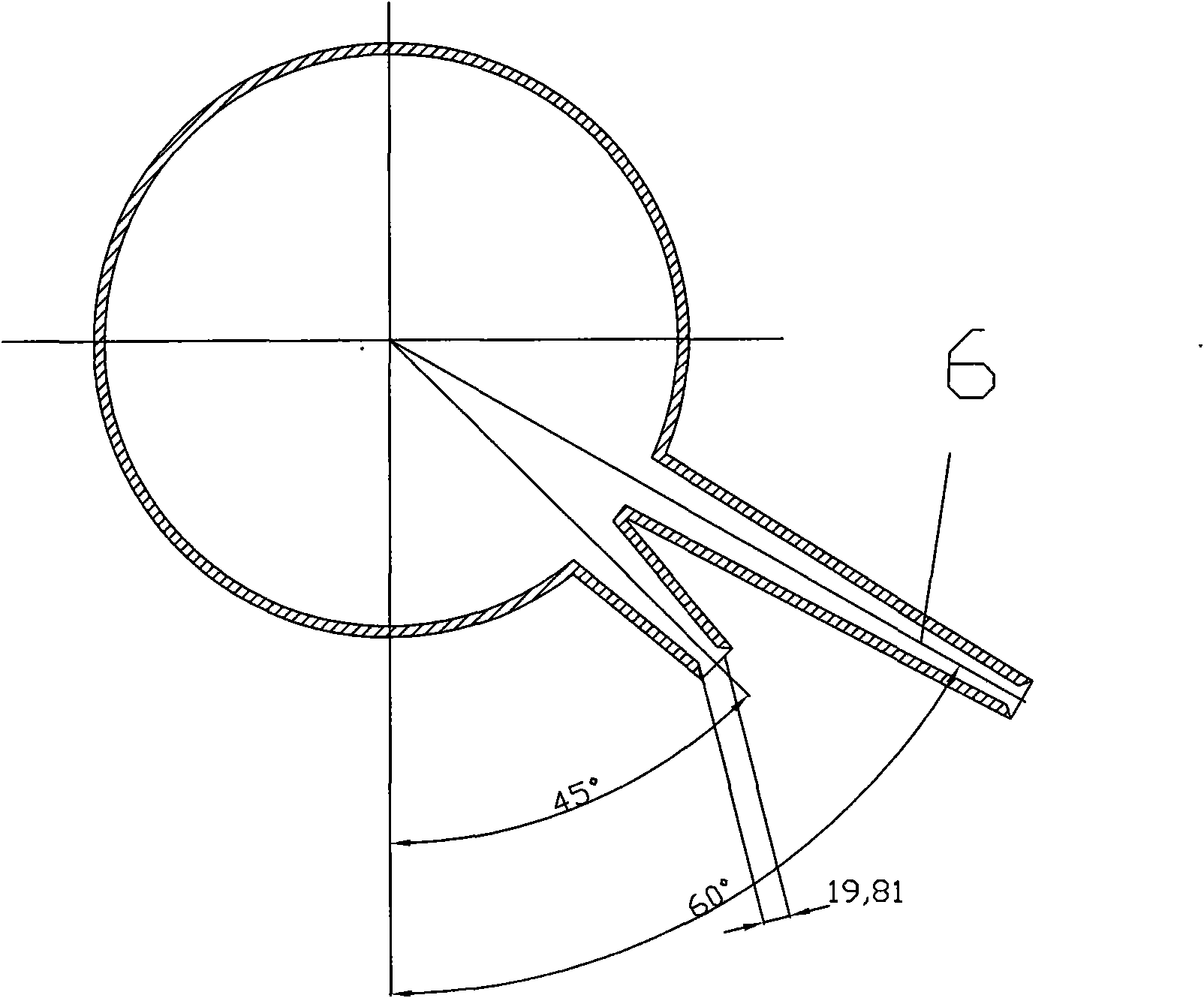

[0021] refer to Figure 1 to Figure 4 , a new type of purging device for cold rolling equipment, including a large-flow centrifugal fan 1, an upper blowing air knife 2 and a lower blowing air knife 3, the large-flow centrifugal fan 1 is connected to a main pipe, and a control device is installed in the main pipe Valve 4, the main pipe communicates with the upper blowing air knife 2 through the upper pipe, the main pipe communicates with the lower blowing air knife 3 through the lower pipe, and the upper blowing air knife 2 and the lower blowing air The knife 3 is fixedly installed on the stand of the cold rolling mill, between the upper blowing air knife 2 and the lower blowing air knife 3 is a blowing station for placing cold-rolled steel plates, and the upper blowing air knife 2 The angle between the plane where the air outlet is located and the longitudinal center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com