Power tool

A technology for power tools and moving parts, which is applied in the field of power tools and can solve problems such as danger and motor damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

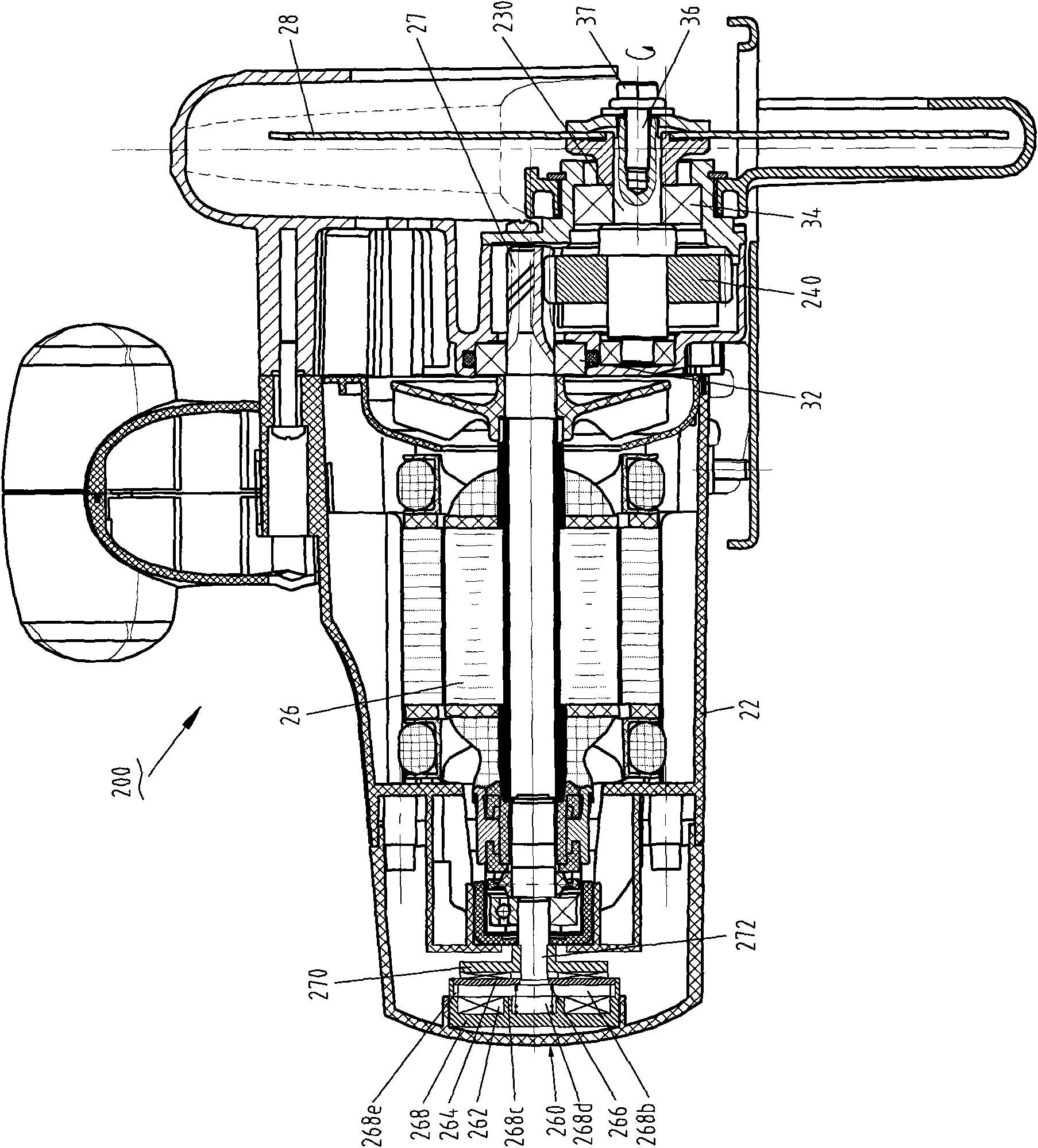

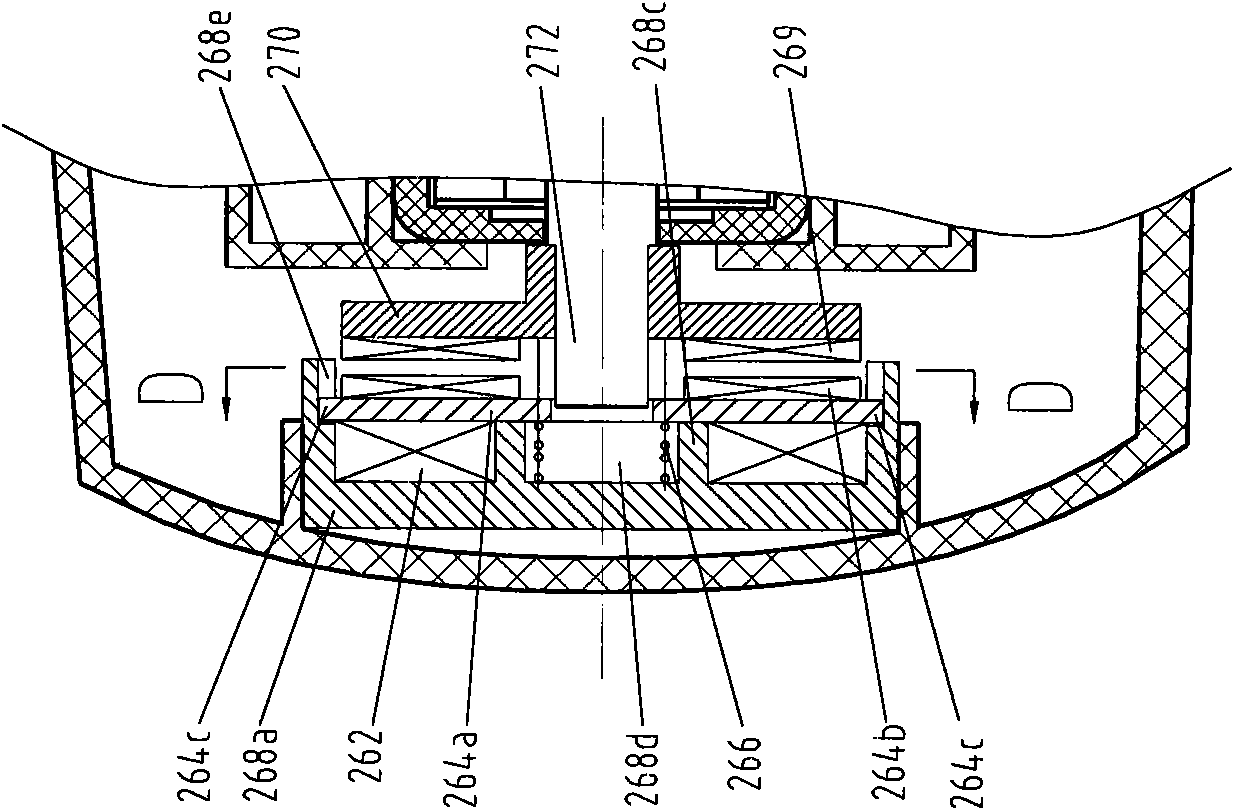

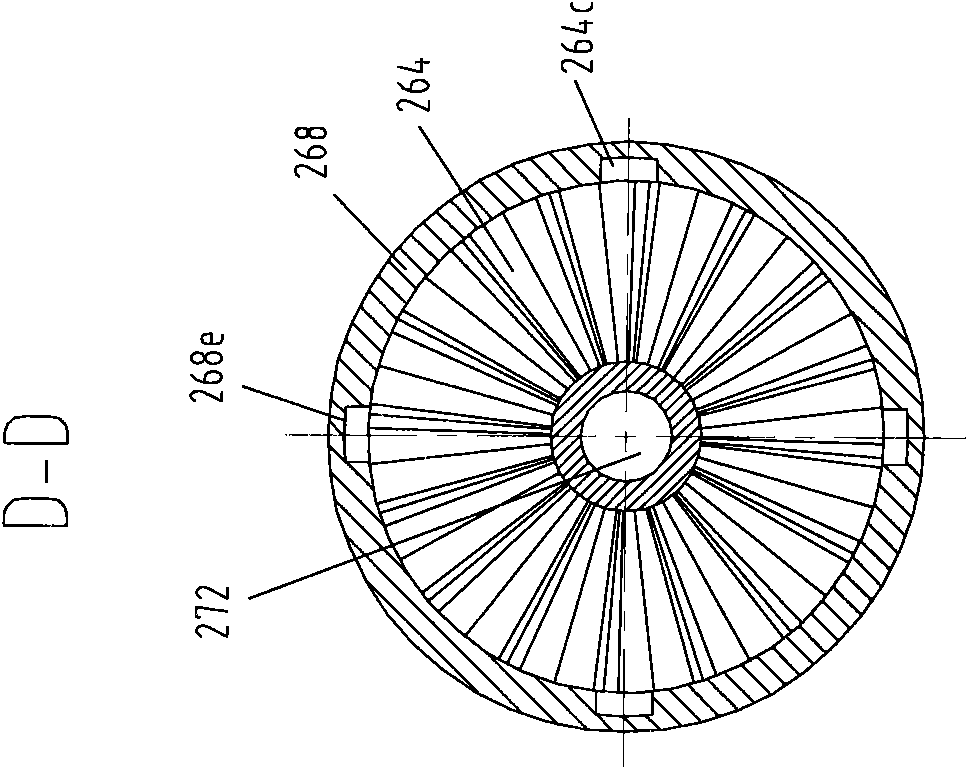

[0051]The present invention takes the electric circular saw and electric wood milling as preferred embodiments to specifically illustrate the shaft locking structure of the power tool. The invention can also be applied to power tools such as angle grinders, sanders, miter saws and large cutters. According to different working occasions of the tool, the output shaft of the power tool and the motor shaft can be arranged parallel to each other, or arranged perpendicular to each other, or arranged at a certain angle. However, the specific setting position will not affect the specific implementation of the present invention. Usually, the output shaft of the electric circular saw is arranged parallel to the motor shaft, while the output shaft of the angle grinder is arranged vertically to the motor shaft. According to the invention, different types of tools can be provided with locking devices in different positions.

[0052] See attached Figure 1~3 , the first preferred embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com