Polysilicon growth ingot furnace

A technology for polycrystalline silicon growth and ingot casting furnace, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of difficult control of thermal field, complex structure, etc., and achieves convenient operation, safe and reliable production, and damage prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

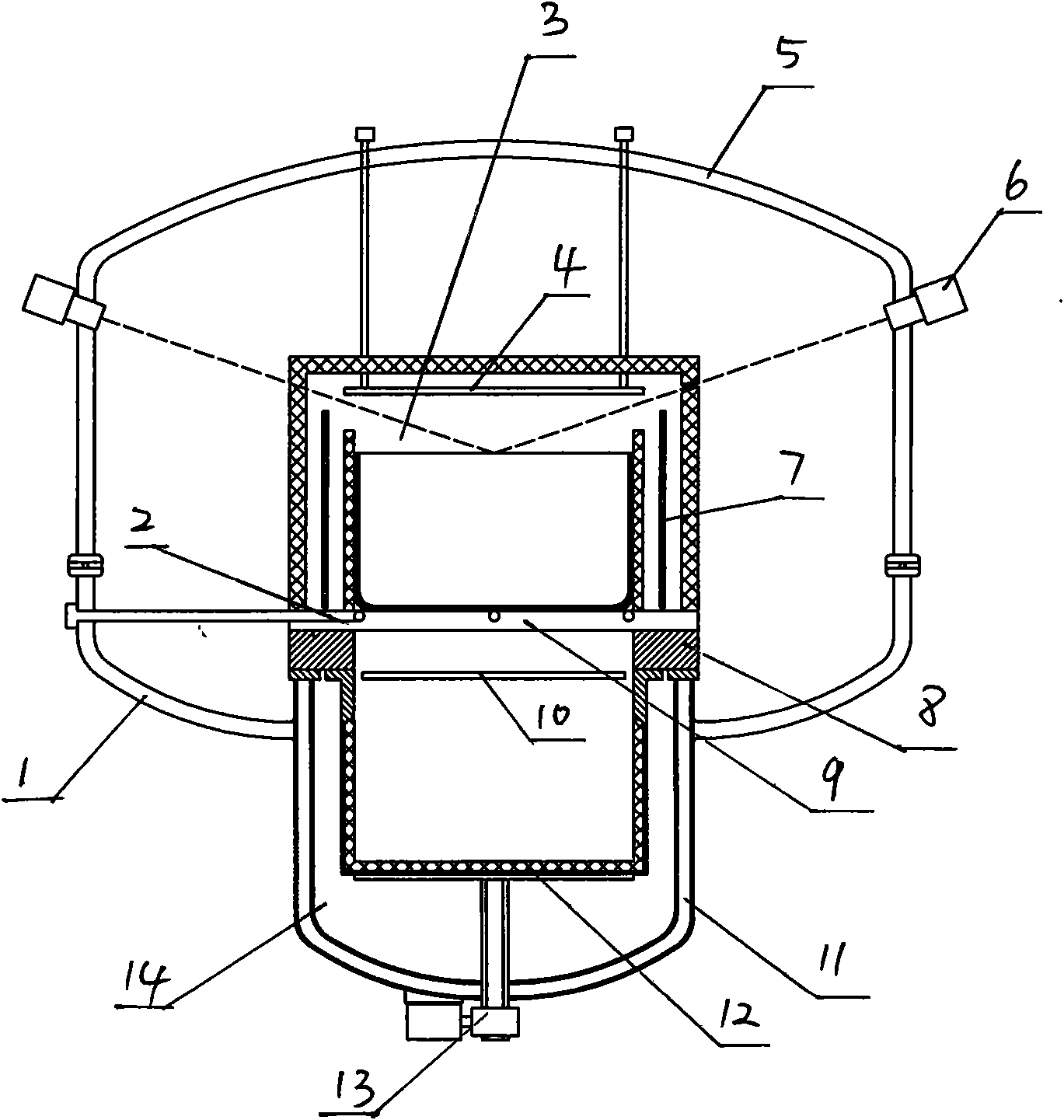

[0009] A double-chamber polysilicon growth ingot casting furnace, which is provided with an upper furnace body 5 and a lower furnace body 1, the upper furnace body 5 is fixed on the upper part of the frame, the lower furnace body 1 is installed on the lower part of the frame through an opening device, and is heated by electric control And the live elements of the control system are arranged at the upper end of the furnace body. The upper furnace body 5 is provided with a fixed upper heating chamber 3, and the upper heating chamber 3 is provided with four walls and an upper cover made of heat-insulating materials. The surrounding heating body 7 and the upper heating body 4 are arranged in the chamber 3, and the load-bearing plate 8 which is buckled with the four walls of the upper heating chamber 3 is arranged under the heat conduction plate 9, and the lower heater 10 is arranged in the middle of the load-bearing plate 8, and the lower heater 10 is arranged on the lower part. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com