Air preheater and production process suitable for same

An air preheater and heat exchange tube technology, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, combustion methods, etc., can solve the problems of poor flue gas circulation, increased thermal resistance of dirt, and easy adhesion of carbon black powder. , to achieve the effect of reasonable and reliable structure design, good heat exchange effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

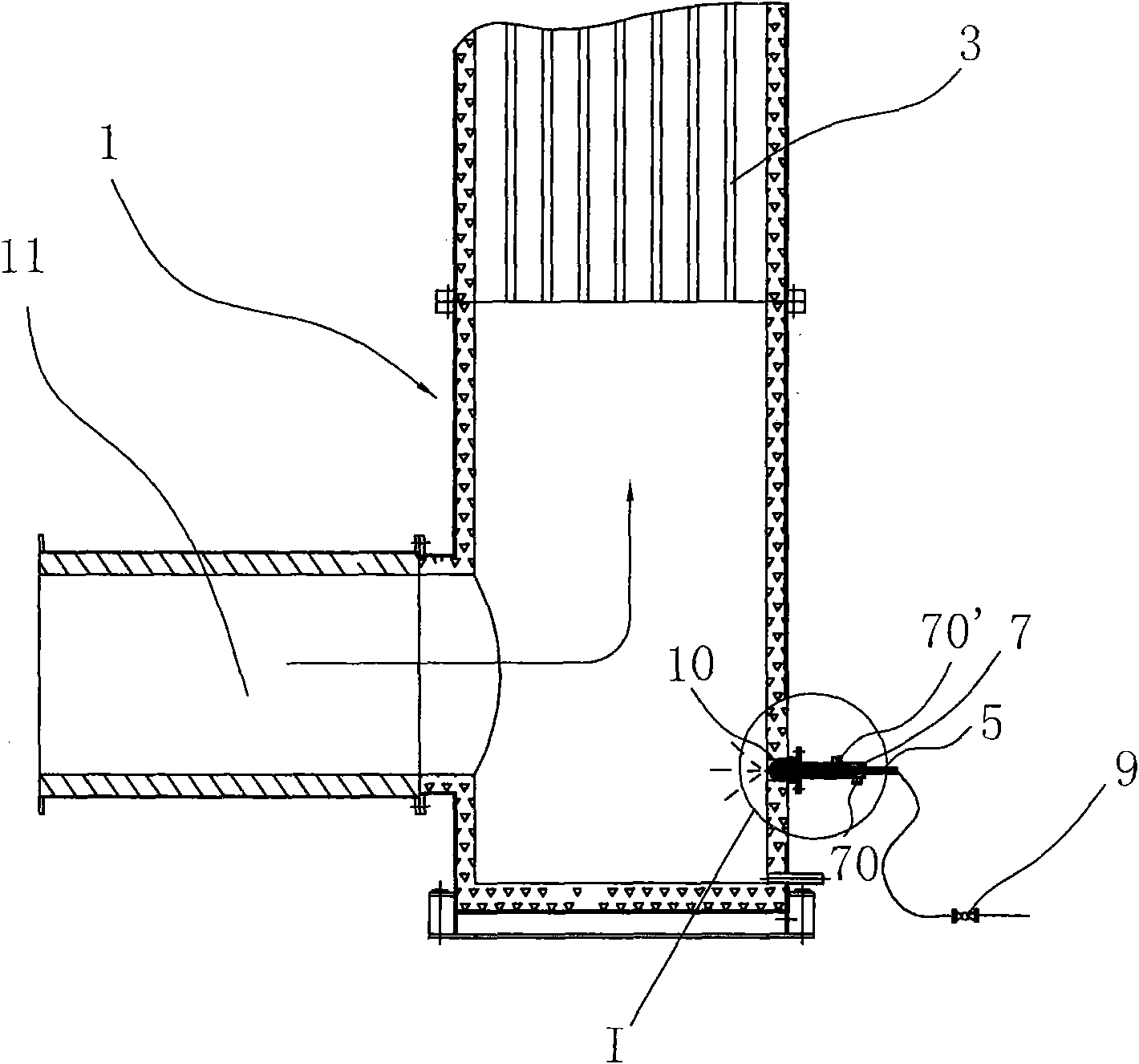

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

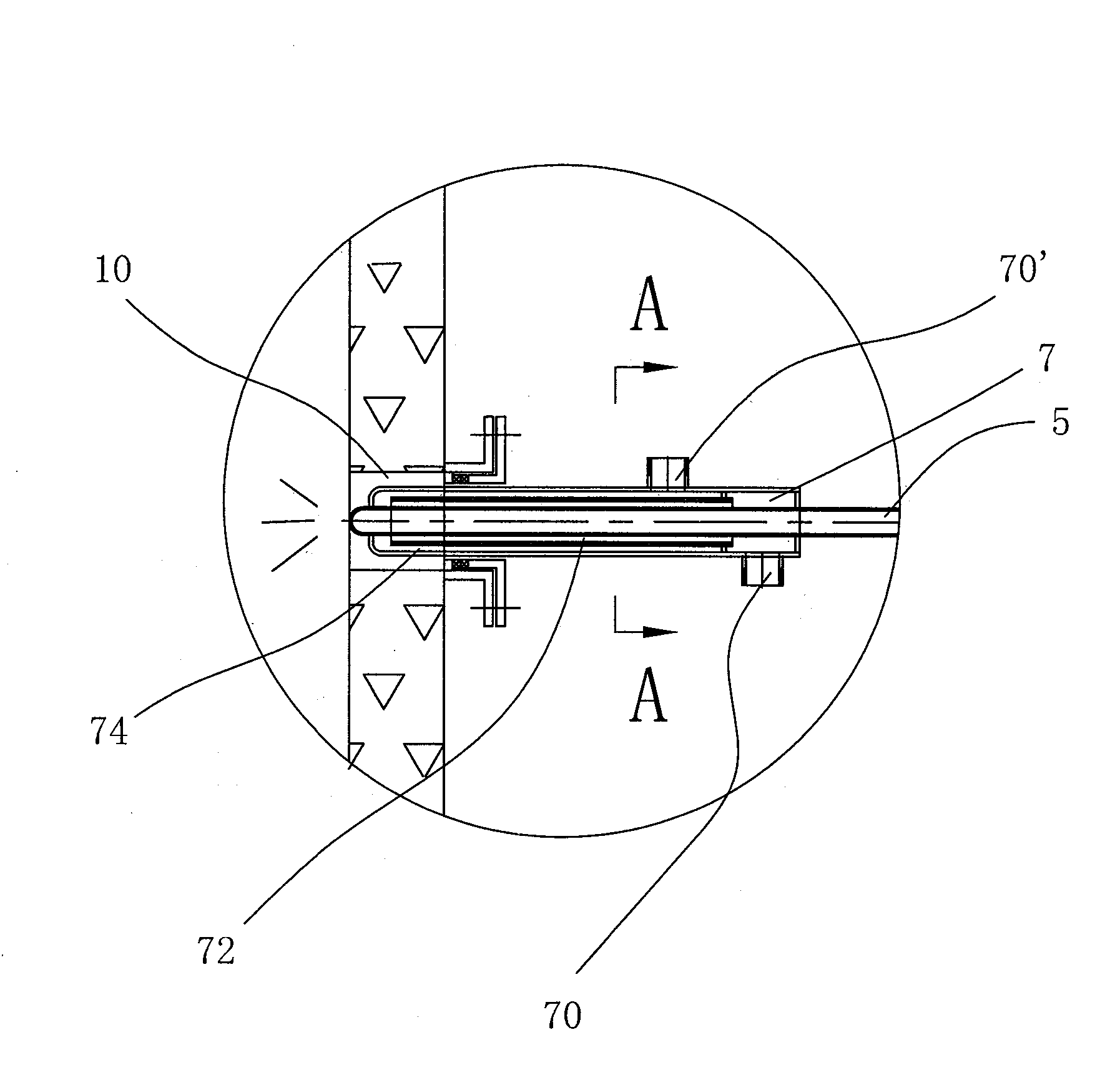

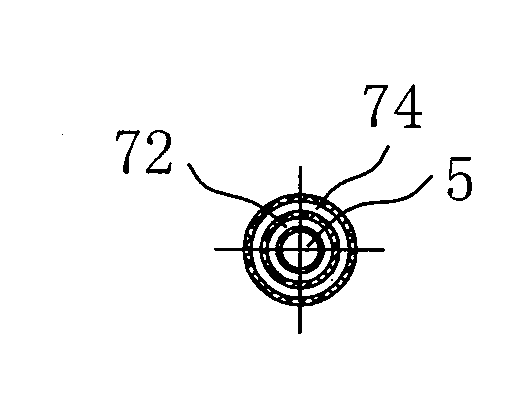

[0027] See Figure 1 ~ Figure 3 , an air preheater, comprising an air preheater main body 1, a flue 11 is arranged on the side wall of the air preheater main body 1, and the flue 11 is connected to a carbon black reaction furnace (not shown in the figure), The main body of the air preheater 1 houses a heat exchange tube 3, and the side wall of the air preheater main body 1 is provided with a water inlet 10 corresponding to the lower part of the heat exchange tube 3, and the water inlet 10 is connected to a pulse type flushing water device. The flushing frequency of the pulse type flushing device is as follows: water is sprayed once every 5-30 minutes, and the water spraying time is 1-5 seconds each time. Of course, the flushing frequency can be properly adjusted according to the heat exchange effect.

[0028] Preferably, the pulse flushing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com