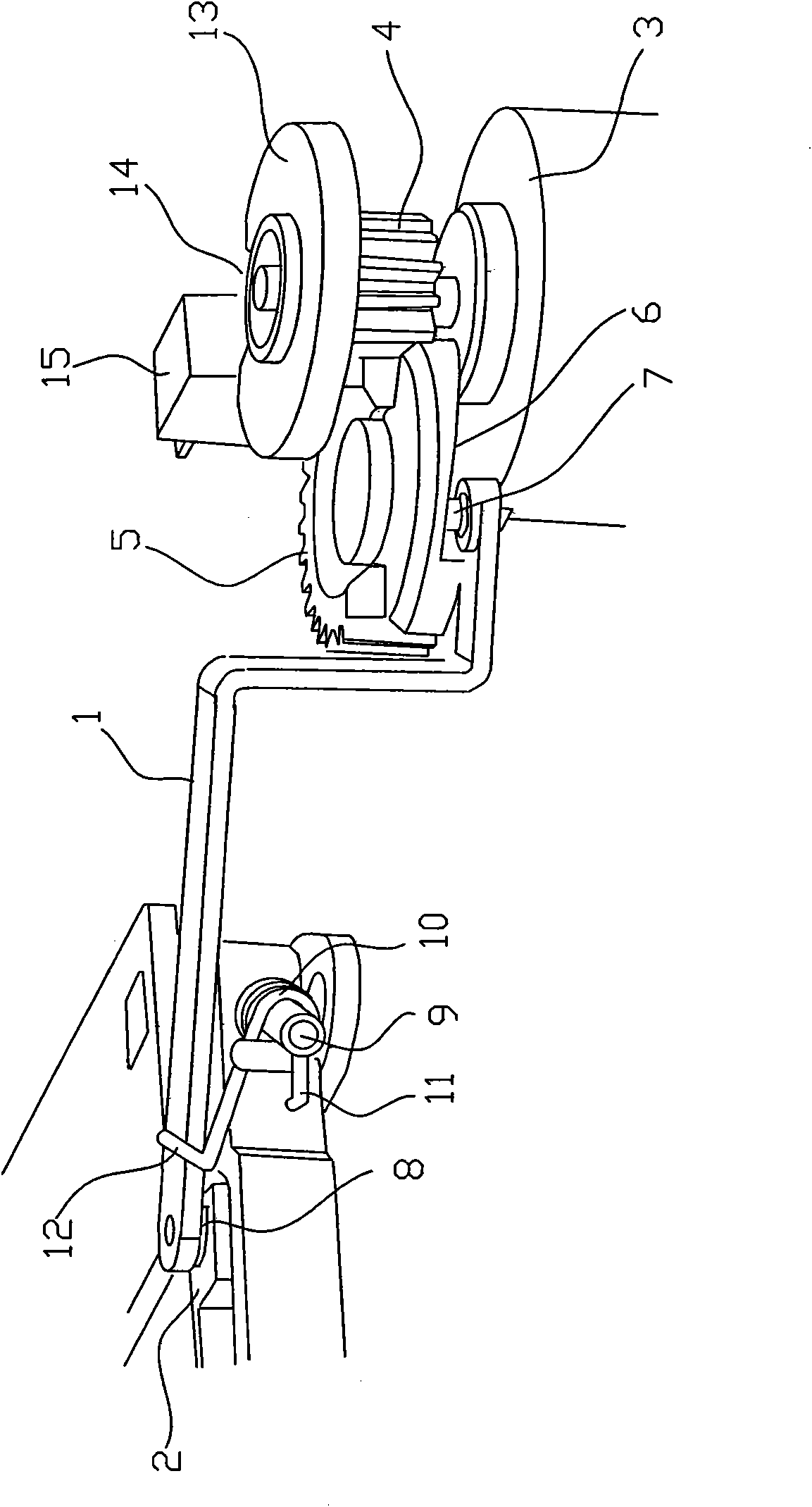

Positioning mechanism of photosensitive unit of hand vibration preventing photography device

A technology of photosensitive unit and positioning mechanism, applied in projection devices, printing devices, optics, etc., can solve the problems of large positioning offset error and insufficient stability, and achieve stable mechanism stability, simple structure, and low precision requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

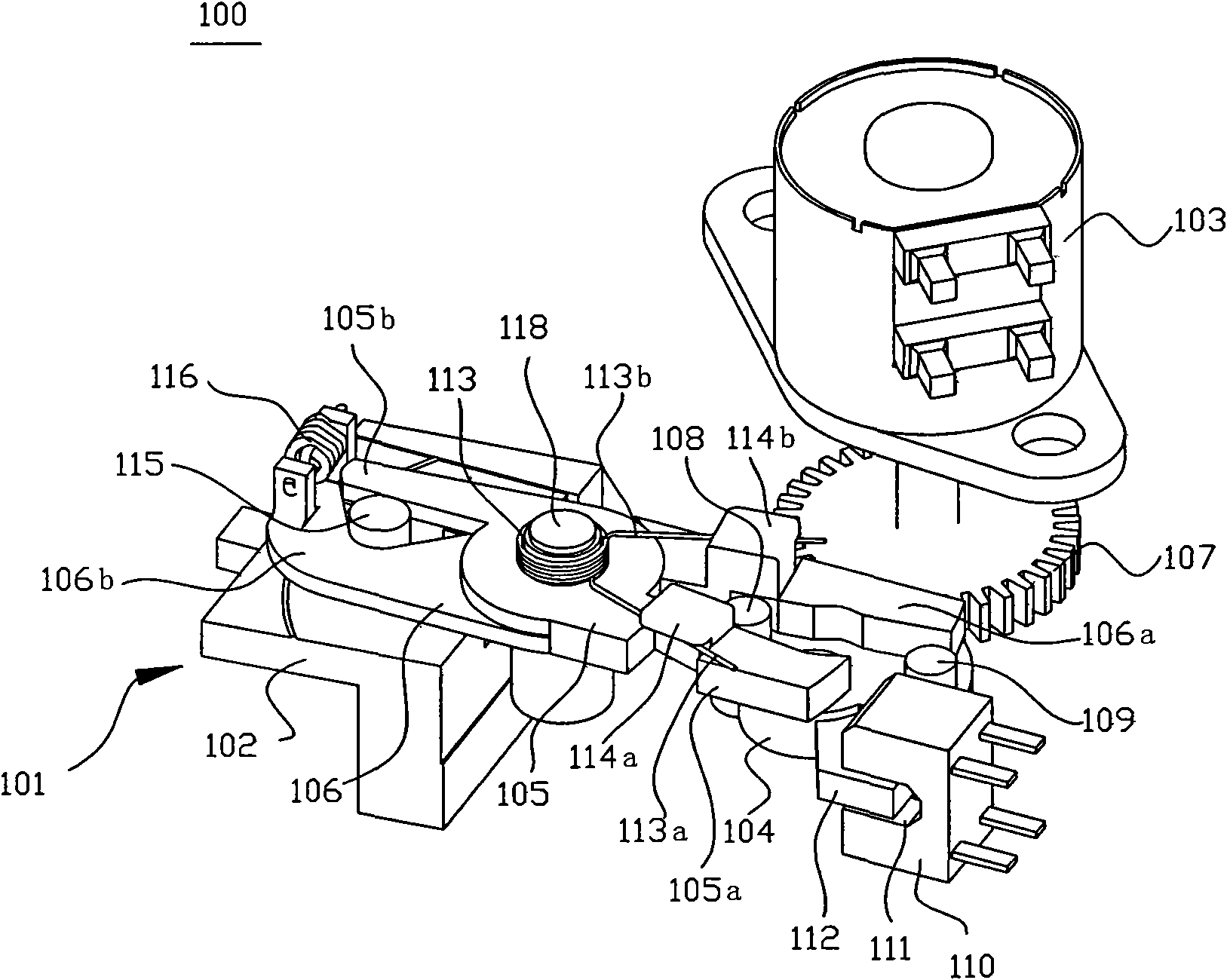

[0030] like image 3 As shown, in the first embodiment of the present invention, the photosensitive unit 101 includes a frame 102 and a photosensitive element (not shown) fixed therein, and the photosensitive element may be, for example, a CCD (Charge Coupled Device, Charge Coupled Device) or a CMOS ( Complementary Metal Oxide Semiconductor Transistor, Complementary Metal Oxide Semiconductor). The positioning mechanism 100 of the photosensitive unit 101 includes: a motor 103 , a cam 104 driven by the motor 103 , and a first positioning plate 105 and a second positioning plate 106 .

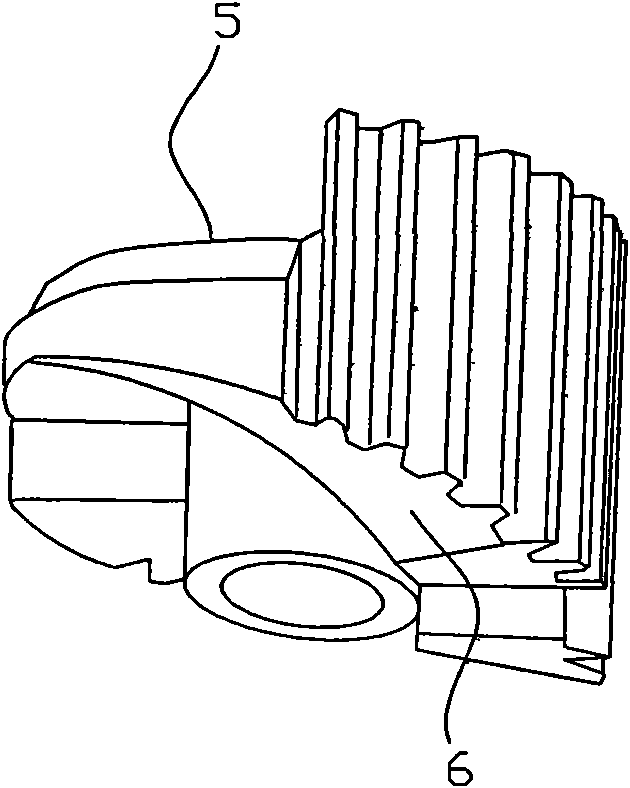

[0031] Wherein, the outer peripheral surface of the cam 104 is provided with a plurality of teeth, and the motor 103 meshes with the cam 104 through the gear 107, and drives the cam 104 to rotate during operation. The cam 104 is provided with a first protrusion 108 and a second protrusion 109 . The cam 104 is provided with teeth only on a part of the outer peripheral surface, and the diameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com